5. Synchronisation

5.1 Synchronisation principles

The controller can be used for synchronisation of generator and mains breaker (if installed). Two different synchronisation principles

are available, namely static and dynamic synchronisation (dynamic is selected by default). This chapter describes the principles of

the synchronisation functions and the adjustment of them.

INFO

In the following, the term "synchronisation" means "synchronising and closing of the synchronised breaker".

5.2 Dynamic synchronisation

In dynamic synchronisation, the synchronising genset is running at a different speed than the generator on the busbar. This speed

difference is called slip frequency. Typically, the synchronising genset is running with a positive slip frequency. This means that it is

running with a higher speed than the generator on the busbar. The objective is to avoid a reverse power trip after the

synchronisation.

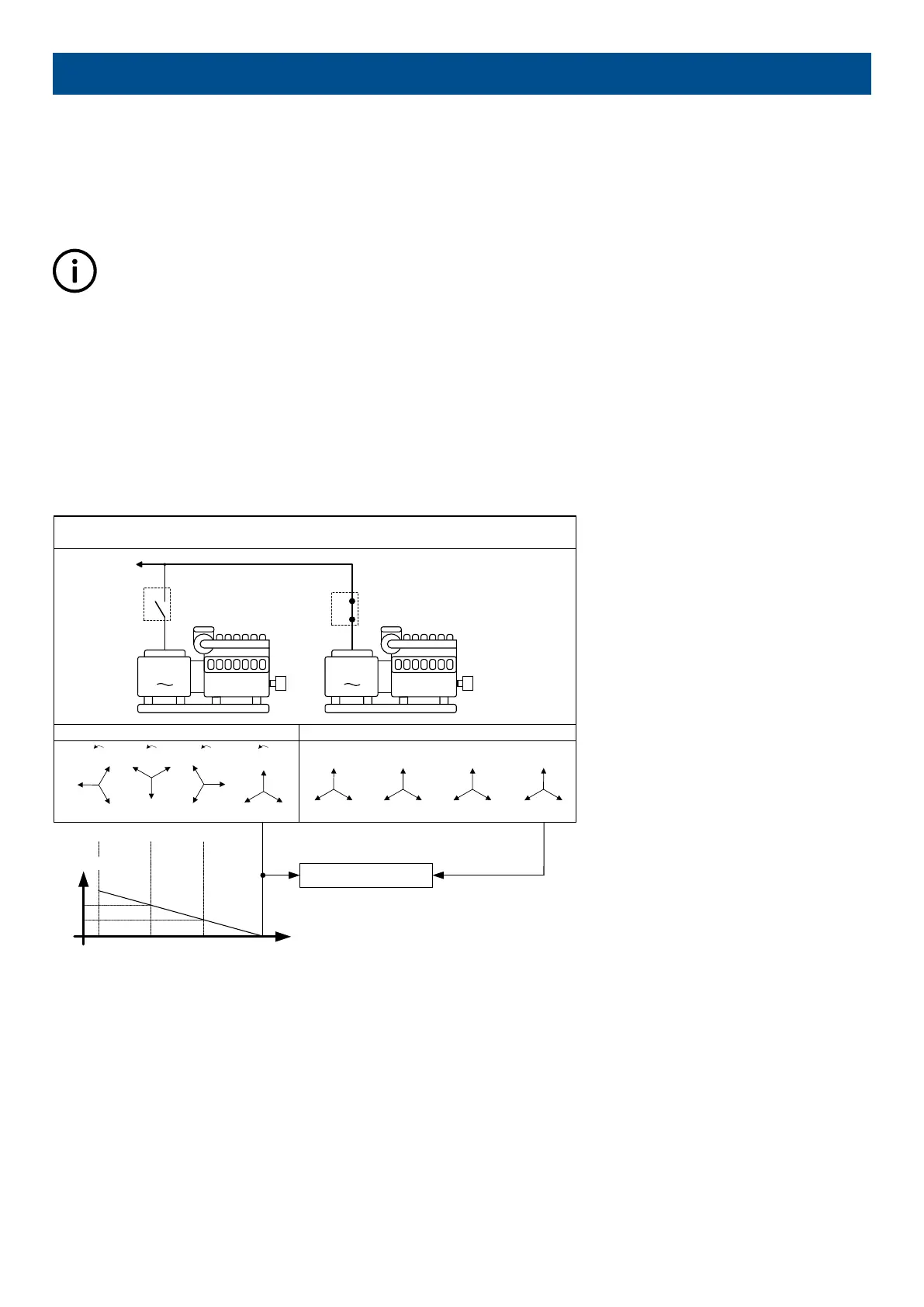

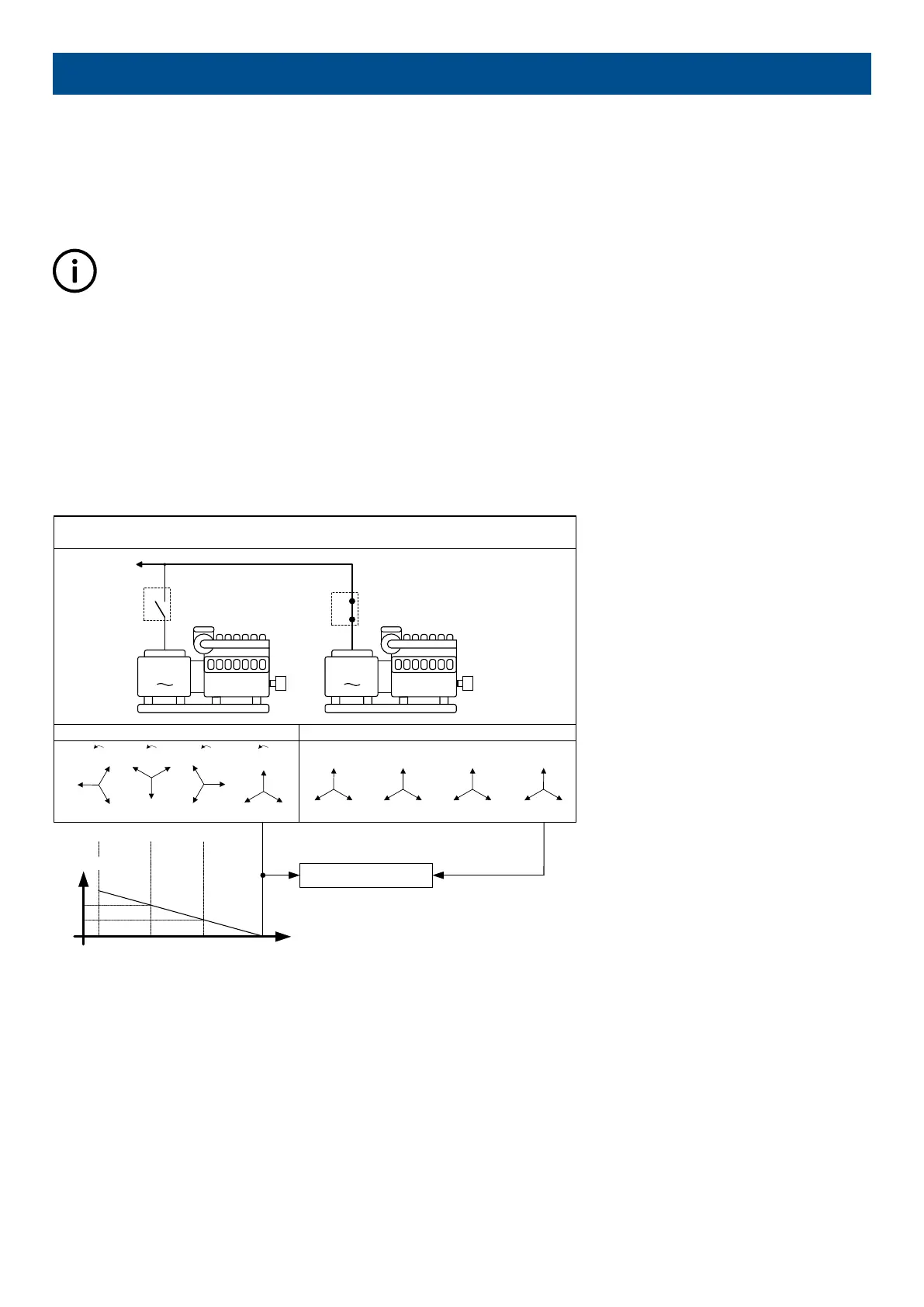

The dynamic principle is illustrated below.

Synchronised

Synchronisation principle – dynamic synchronisation

Speed:

1503 RPM

50.1 Hertz

Speed:

1500 RPM

50.00 Hertz

LOAD

G

GB

G

GB

L1

L2L3

L1

L2L3

L1

L2L3

L1

L2L3

Generator on loadSynchronising generator

L1

L2L3

L1

L2

L3

L1

L2 L3

L1

L2

L3

2.5 s 7.5 s5.0 s0 s

∆t [s]

180°

90°

0°

Angle

L1

gen

/L1

bus

[deg]

In the example above, the synchronising genset is running at 1503 RPM ~ 50.1 Hz. The generator on load is running at 1500 RPM ~

50.0 Hz. This gives the synchronising genset a positive slip frequency of 0.1 Hz.

The intention of the synchronising is to decrease the phase angle difference between the two rotating systems. These two systems

are the three-phase system of the generator and the three-phase system of the busbar. In the illustration above, phase L1 of the

busbar is always pointing at 12 o’clock, whereas phase L1 of the synchronising genset is pointing in different directions due to the

slip frequency.

DESIGNER'S HANDBOOK 4189341275A EN Page 85 of 196

Loading...

Loading...