Instructions for use Carina SW 3.2n 109

Reprocessing

Validated reprocessing procedures

The suitable reprocessing procedures result from

the classification.

The effectiveness of the reprocessing procedures

listed has been validated by independent laborato-

ries which are certified to ISO 17025.

At the time of validation, the following reprocessing

procedures were effective and compatible with the

materials used.

Reprocessing non-critical components

Surface disinfection with cleaning

1 Remove soiling immediately. To remove, use a

cloth moistened with disinfectant.

2 Perform surface disinfection.

3 After the contact time has elapsed, remove dis-

infectant residue.

4 Check the product for visible contamination.

Repeat steps 1 to 4 as required.

5 Check product for visible damage and replace it

if necessary.

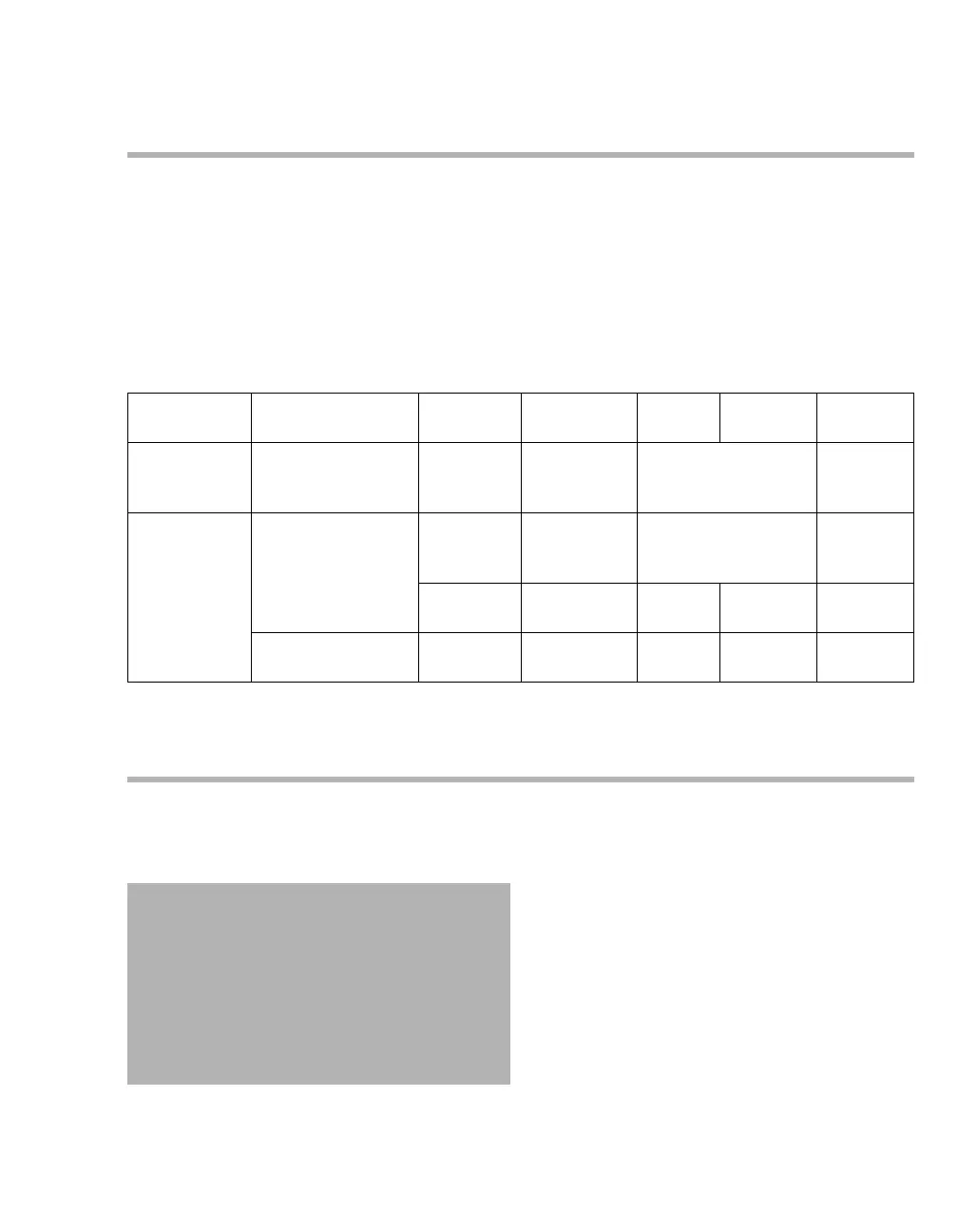

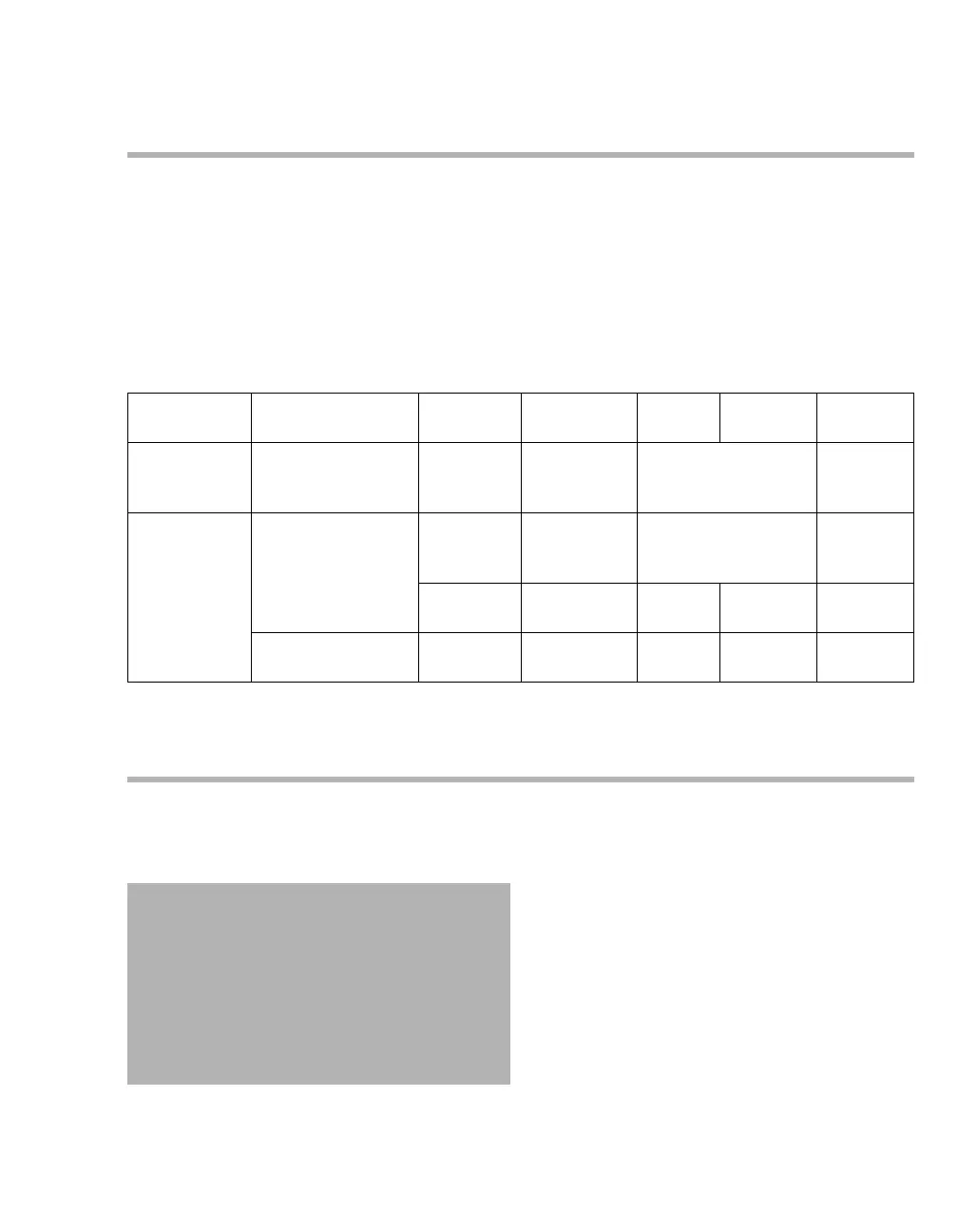

Classification Procedure Agent Manufac-

turer

Concen-

tration

Contact

time

Tempera-

ture

Non-critical Surface disinfection

with cleaning

Virex TB Diversey Dosing and contact

time as specified by

manufacturer

–

Semi-critical A

and B

Machine cleaning

followed by thermal

disinfection

Neodisher

MediClean

Dr. Weigert Dosing and contact

time as specified by

manufacturer

–

–– –10min93°C

(199.4 °F)

Steam sterilization – – – 5 min 134 °C

(273.2 °F)

WARNING

Risk from penetrating liquid

Penetrating liquid my cause the following:

– Damage to the device

– Electric shock at switch-on

– Device malfunctions

Make sure that no liquid penetrates into the

device.

Loading...

Loading...