MAINTENANCE, SERVICE AND FAULT FINDING

4-62 25364 Issue 8 March 2018

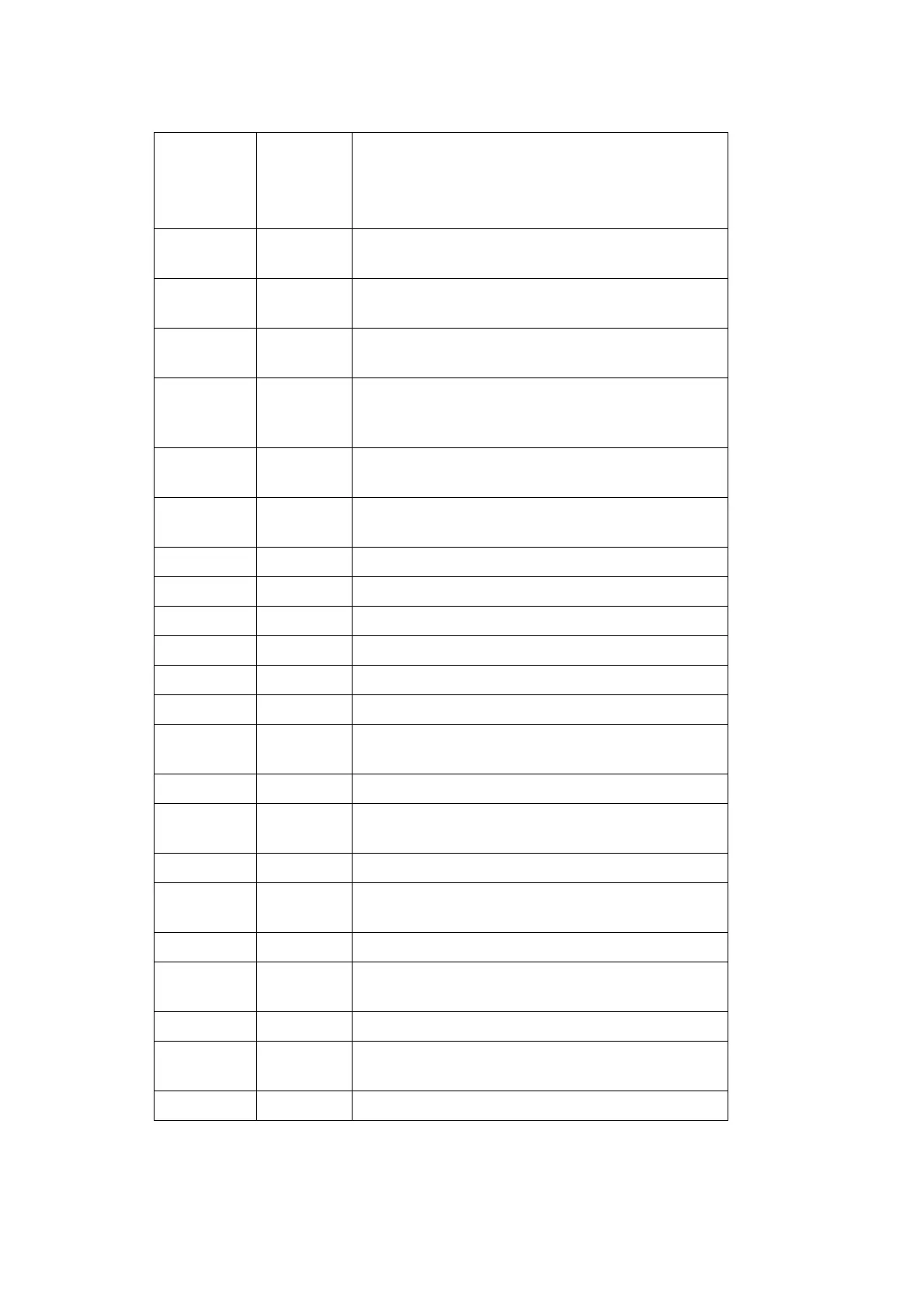

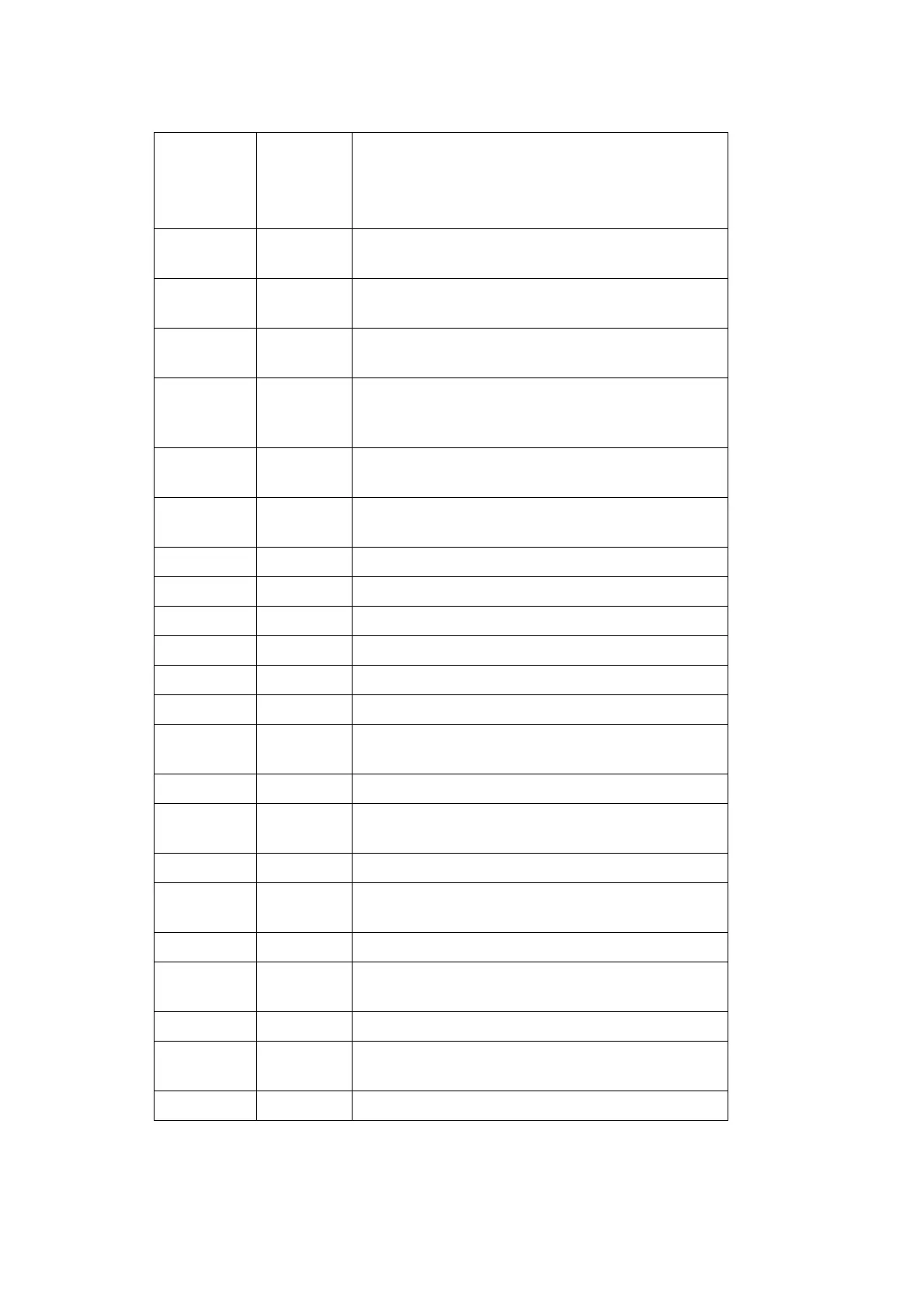

Is the substrate surface clean and suitable for

Thermal Transfer printing?

Is the dwell time sufficient for the amount of print

required?

Is the parent machine giving the printer a print

signal?

Is there too much / not enough start pulse

offset? Is the substrate still moving when

printing?

Is the encoder wheel turning and sending pulses

to the controller?

Is the parent machine advancing the substrate

correctly?

Check that contrast is set to 80 - 100%

Check that preheat is set to 90 - 100%

Check that Ribbon Economy is initially set to 4%

Check that Retraction Offset is set to 1mm

Check that Retraction Offset is set to –1mm

Check that Y-Offset is set to 1 - 2mm

Check that Y-Offset is set to 30mm (dependent

upon speed)

Check that Head down is set to 30ms

Check that Head down is set to 40ms

(dependent upon speed)

Check that Head up is set to 15ms

Check that Head up is set to 15ms (dependent

upon speed)

Check that Motor start offset is set to 6mm

Check that Motor start offset is set to 12mm

(dependent upon speed)

Check that Motor stop offset is set to 2mm

Check that Motor stop offset is set to 5mm

(dependent upon speed)

Is the print head resistance set correctly?

Setting/

Condition

Applicable

to IM

Setting/

Condition

Applicable

to CM

Setting/Condition to Check

Loading...

Loading...