MAINTENANCE, SERVICE AND FAULT FINDING

25364 Issue 8 March 2018 4-61

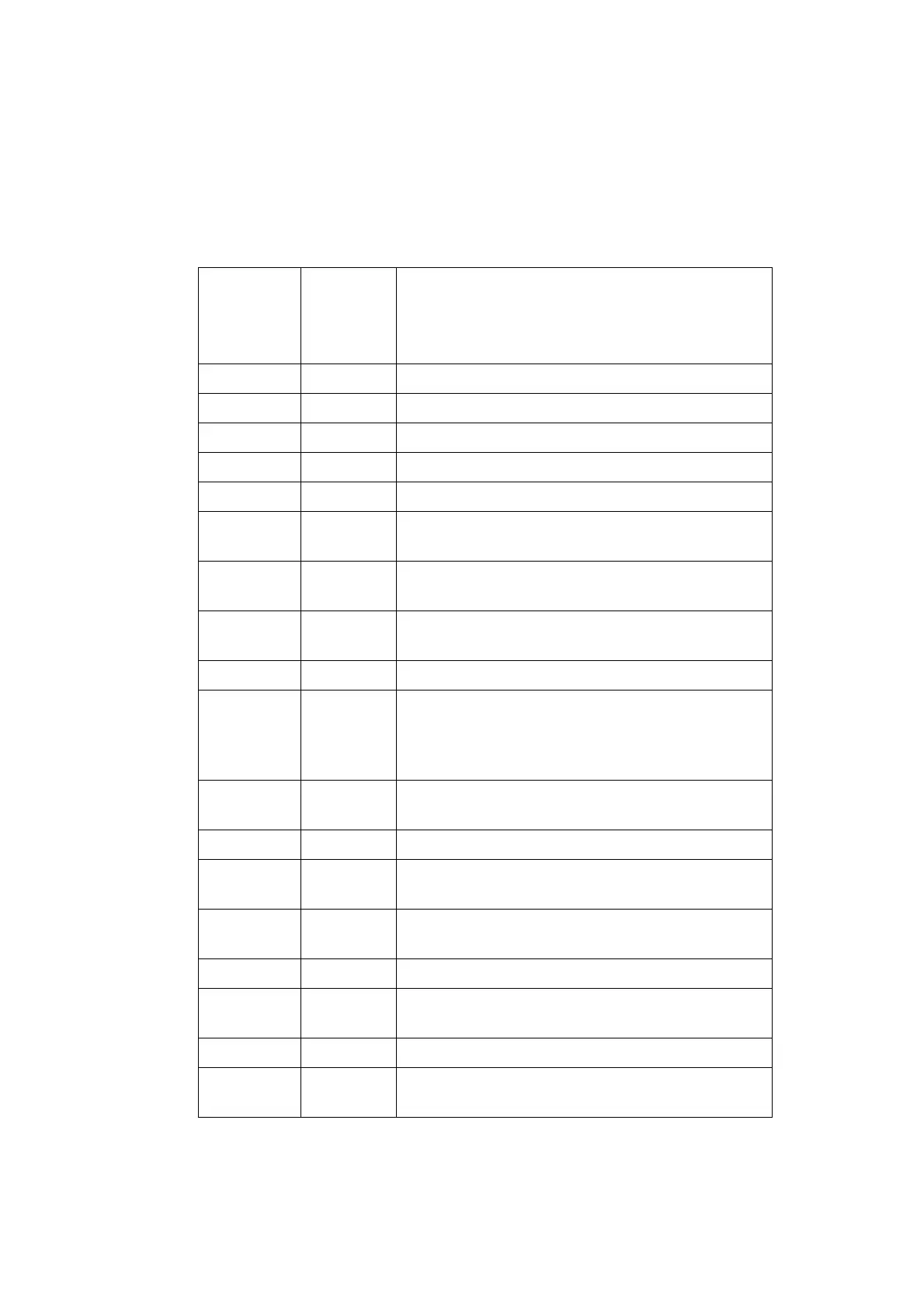

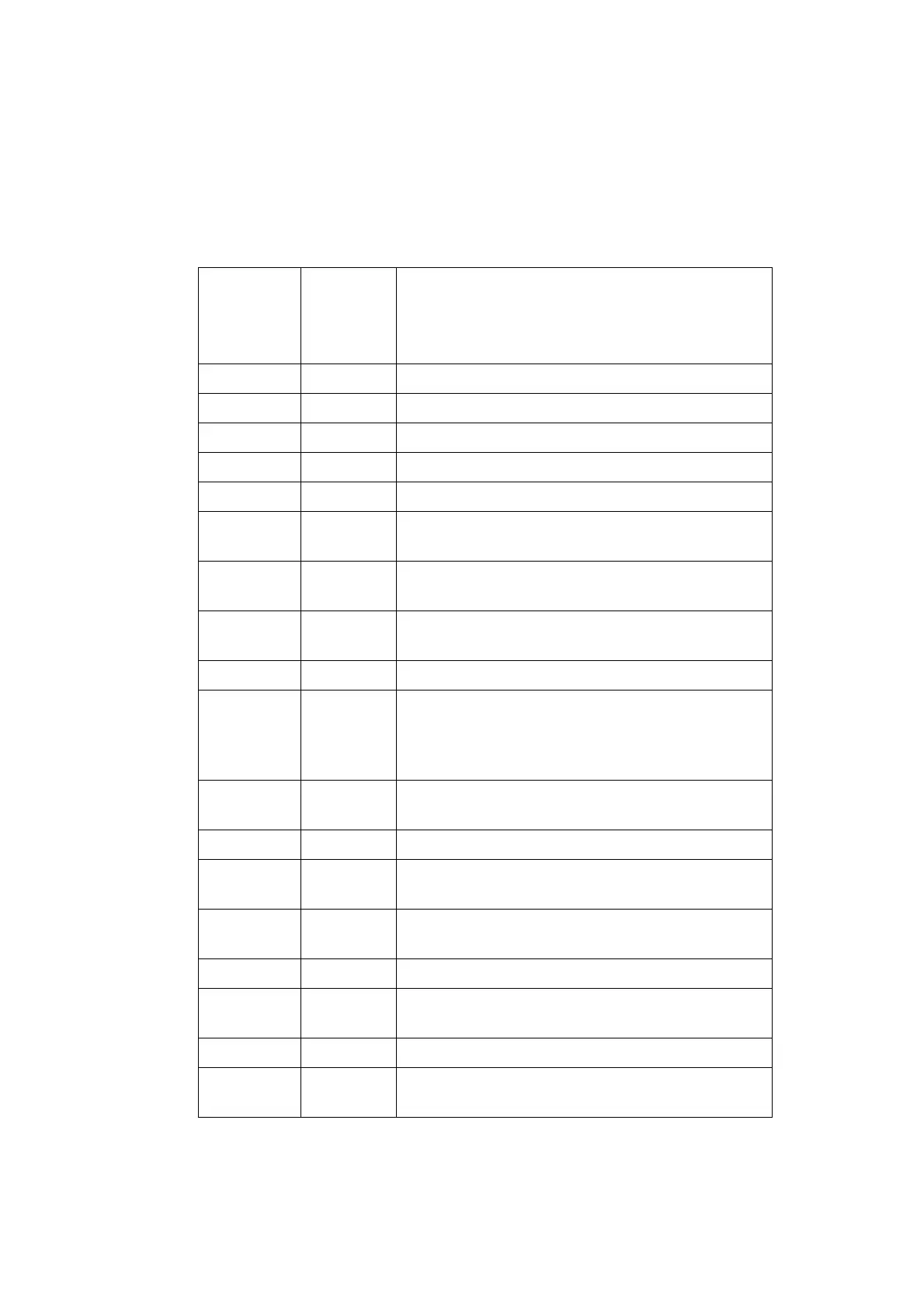

TROUBLESHOOTING GUIDE

Print Problems

When poor print quality occurs, check the following list to ensure that

settings/conditions are correct:

Setting/

Condition

Applicable

to IM

Setting/

Condition

Applicable

to CM

Setting/Condition to Check

Is the printer in ‘Ready’ mode and able to print?

Is the print head clean?

Is the print base rubber clean and undamaged?

Is the print roller clean and undamaged?

Is the printer level in its frame?

Is the gap between the print head and substrate

about 0.2-2.0mm in pre-print position?

Is there adequate air pressure (normally set to

approximately 2.5 - 3.5 bar)?

Is the print head gap even along its length

compared to the substrate?

Is the print head parallel to the print roller?

Is the print head set to ‘Top Dead Centre’ on the

print roller? Bear in mind the printer

may operate slightly better 1 – 2mm before or

after ‘TDC’

Is the print head set at the correct / optimum

angle?

Is the print head damaged?

Is the speed of the parent machine set too high?

Up to 30M/min is acceptable.

Is the speed of the parent machine set too low?

Above 3M/min is acceptable.

Is the ribbon correctly wound on the spindle?

Are the ribbon guide rollers clean, running freely

and unmarked?

Is the tension on the ribbon set correctly?

Is the ribbon of the correct specification for the

printer and substrate?

Loading...

Loading...