Conguraon

Before operang the pump congure the motor controller sengs so that they are suitable for

the applicaon.

If the system is designed to operate with parallel control and monitoring, there is no facility to

change the majority of the motor controller sengs once the pump is installed on the system.

The pump is supplied with all sengs at factory default values, as shown in Table 45 on page

95. If any of the motor controller sengs are to be changed, change them before installing

the pump on the system.

The pump can be congured using the customer serial comms over the serial interface.

Congure the pump using serial commands on page 35 details the commands that will be

needed to congure the motor controller. Alternavely, use the Edwards TIC Turbo and

Instrument Controller, TIC Turbo Controller or TAG Controller. Further informaon regarding

this is detailed in . The Edwards nST PC soware can also be used to congure the pump, either

via the serial interface or via the USB service port.

Note:

The standby speed may be adjusted using the buon on the motor controller as described in

Standby speed seng on page 39.

If the pump is operated with parallel control and monitoring and the controller sengs will not

be recongured, go straight to Before starng the pump on page 44.

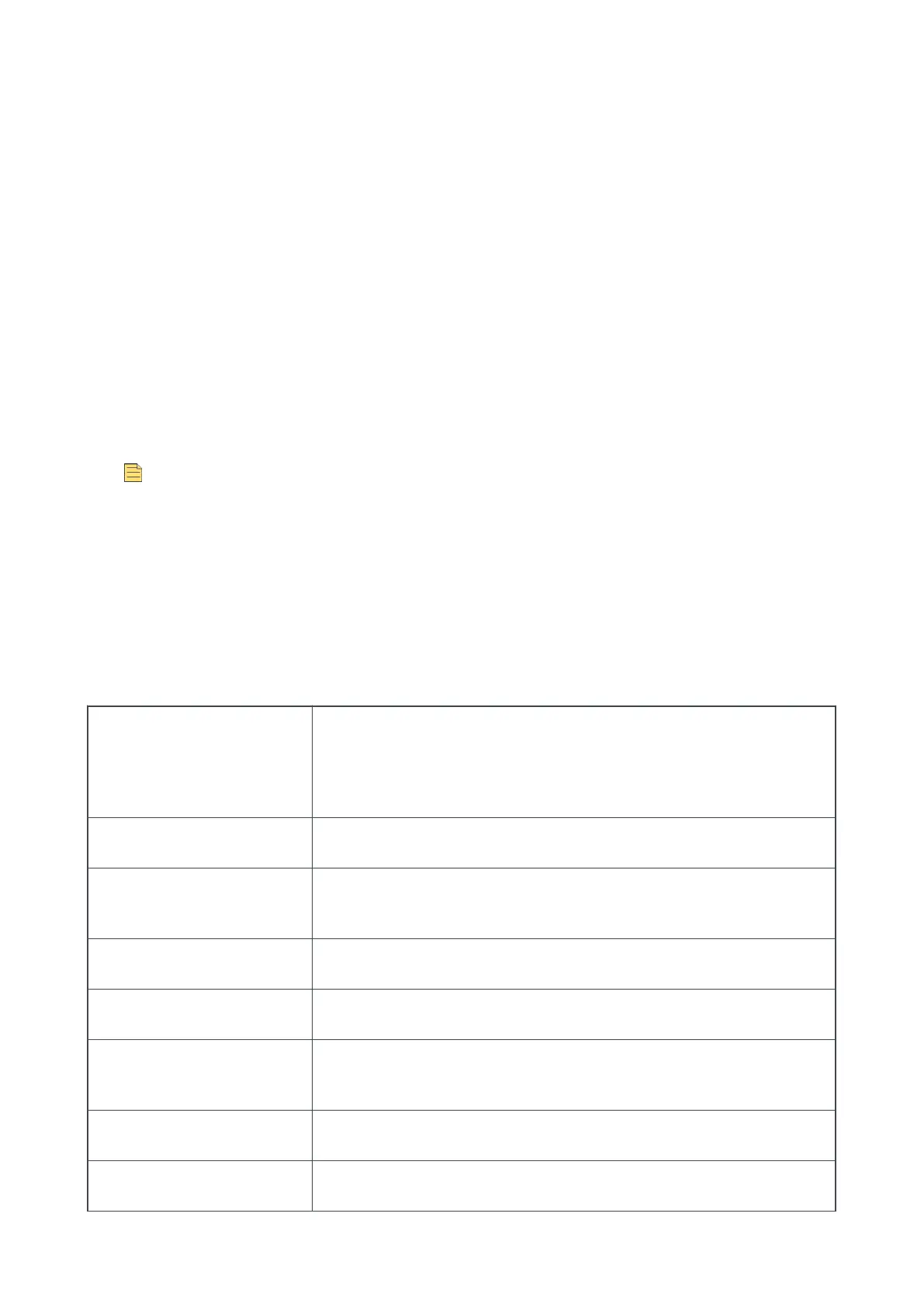

Congure the pump using serial commands

Refer to Table 45 on page 95 for a summary of the full set of serial commands, parameter

ranges and factory defaults for each

seng.

Message structure The message structure and command set are the same for RS485 and

RS232 opons. To communicate a message to the nEXT85 pump, the

characters must be sent in a specic order. If the message does not

conform to the correct structure it will be ignored and no reply will be

sent.

Command and reply table

denions

Explanaon of the command and reply characters.

Power limit seng The pump is supplied with a default power limit. If this limit is not suitable

for the applicaon, change it to any value between the maximum and

minimum seng.

Powering a fan from the motor

controller

A fan can be powered from the nEXT85 motor controller on auxiliary

output 2.

Controlled venng opons If the motor controller is used to automacally control a vent valve, there

are a number of venng opons available.

Standby speed seng The pump can be run at standby speed rather than full rotaonal speed.

The standby speed is a user-congurable opon and can be set to any

value between 55% and 100% full rotaonal speed.

Normal speed seng The normal speed is a user-congurable seng and can be set to any

value between 50% and 100% full rotaonal speed.

Timer seng and opons The meout period is a user-congurable opon and can be set to any

value from 1 to 30 minutes.

B8G0-00-880A - Conguraon

Page 35

Loading...

Loading...