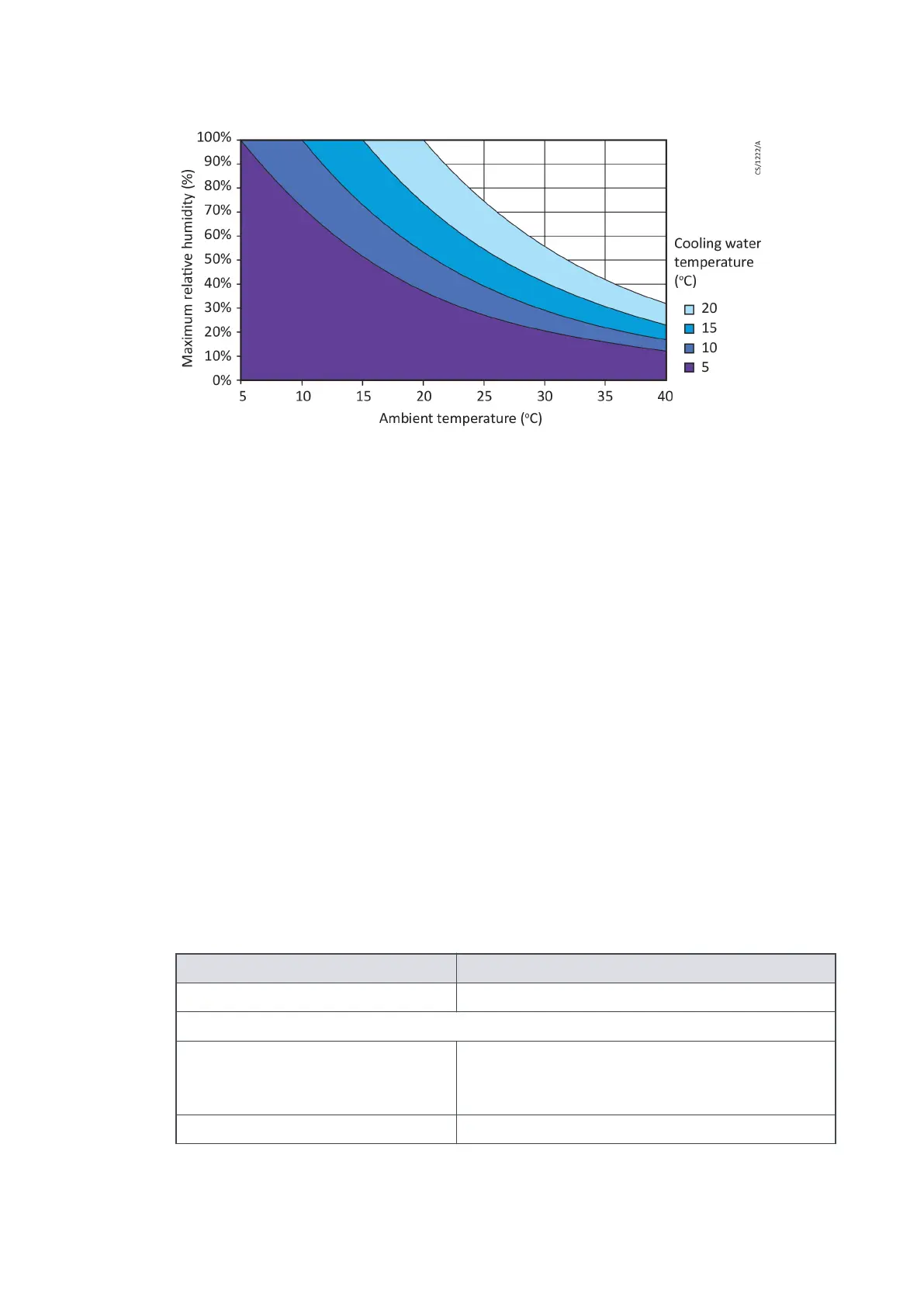

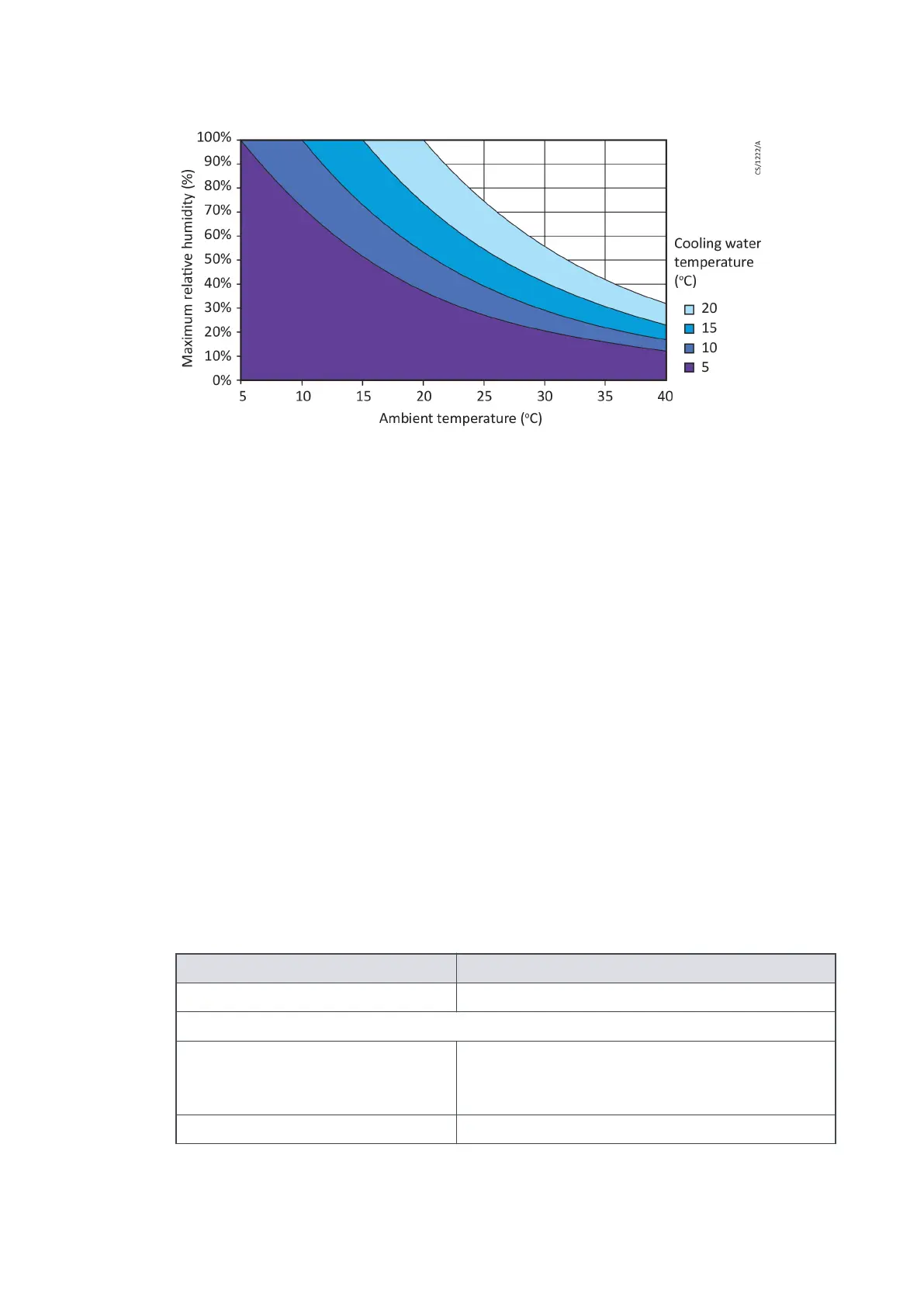

Figure 16

Maximum relave humidity to avoid condensaon with water cooling

Electrical data

The nEXT85 pumps can be driven by either the customers system or by the Edwards TIC Turbo

Instrument Controller, TIC Turbo Controller or TAG Controller.

If using the customer system, an appropriate, pre-approved, UL/CSA rated 24 - 48 V d.c. power

supply should be used. The size of the power supply required depends on the applicaon and

the power limit congured in the nEXT85 pump. The power limit seng determines how

quickly the pump ramps up and dictates the size of the power supply required. If serial

communicaons is available, the power limit seng of the nEXT85 pump can be selected.

Refer to Table 43 on page 91 for the maximum power limit sengs for nEXT85 pumps. If the

applicaon requires rapid cycling of the pump, faster ramp mes can be achieved if the power

supply delivers higher current, up to a maximum in accordance with Table 43 on page 91.

If the facility to adjust the power limit seng is not available, use a power supply capable of

delivering enough current to meet the Edwards factory default power limit seng, shown in

Table 43 on page 91.

Logic interface connector

nEXT85 pumps have a 15-way logic interface connector on the end of the logic interface cable.

Use a suitable connector mang half (not supplied) to connect the nEXT85 pump to the

customer equipment. Refer to the following table for the connector mang half type.

Table 43

Logic interface technical data

Logic interface items

Connector

*

15-way D-type male

nEXT85 pumps electrical supply:

Allowable voltage range

(including any ripple)

24 V d.c. to 48 V d.c. +5%, -10%

(21.6 V d.c. to 50.4 V d.c.)

Maximum voltage ripple 0.5 V rms

B8G0-00-880A - Technical Reference

Page 91

Loading...

Loading...