Chapter 6: Preventive maintenance and testing

150 EST3X Technical Reference Manual

Visual inspections

Perform visual inspections in accordance with Table 34, or more often if required

by the local AHJ. See Table 36 on page 157 for test methods.

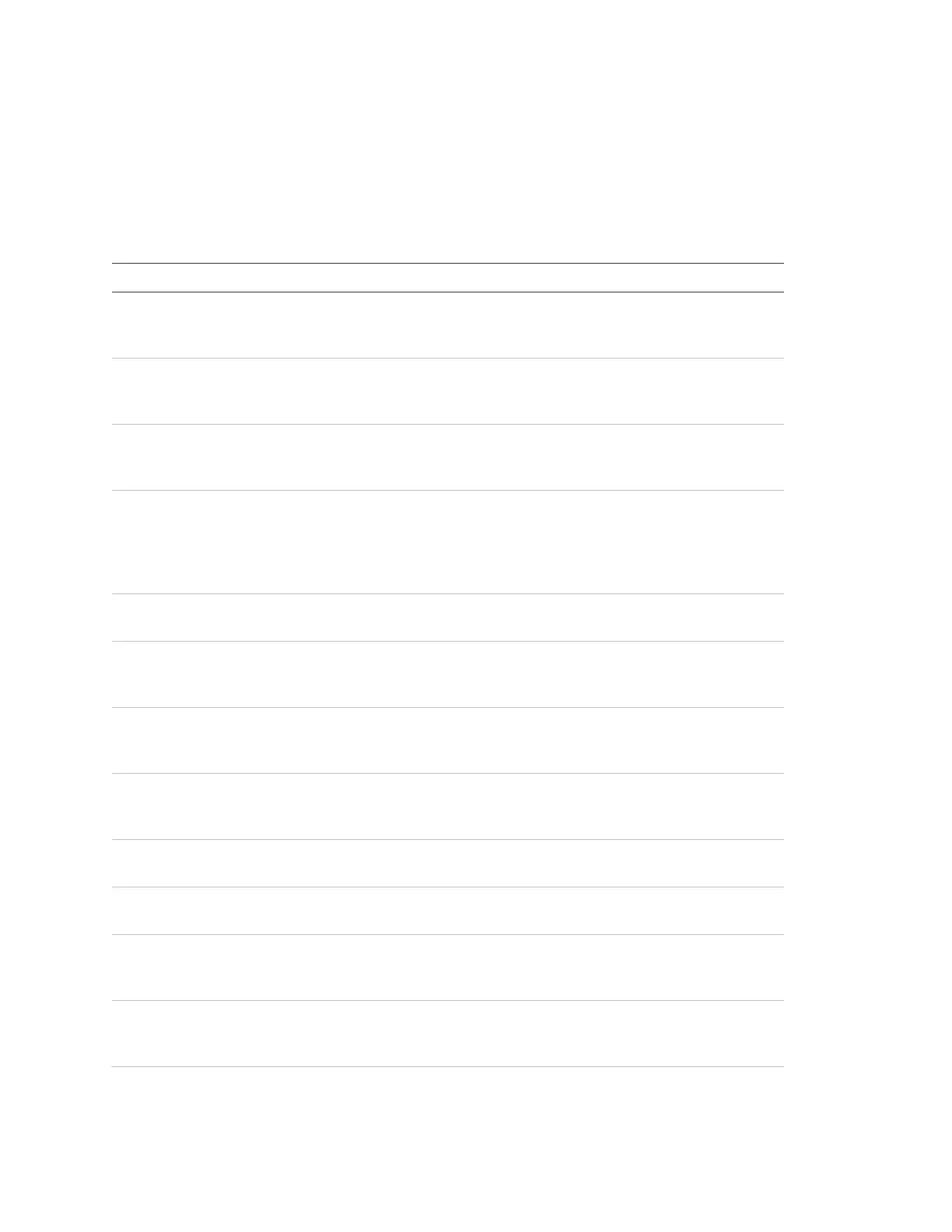

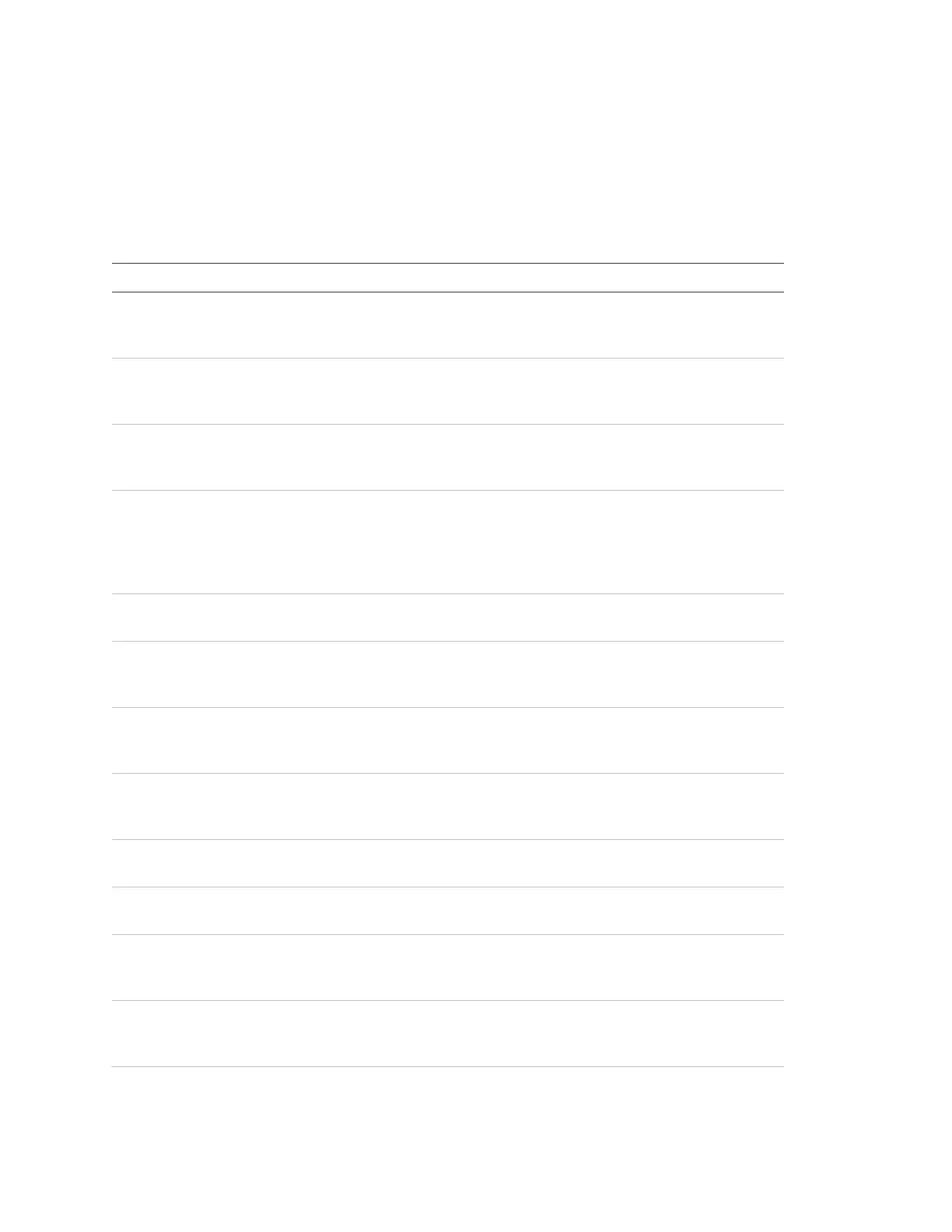

Table 34: Visual inspection schedule

Frequency Recommended procedure

Radiant energy fire detectors

Monthly Inspect the equipment for any visible signs of

damage or other changes that may adversely

affect performance. Clean if necessary.

Supervisory signal devices

Monthly Verify that the module’s green LED flashes.

Ensure there are no changes that may adversely

affect equipment performance.

Monthly Verify that the module’s green LED flashes.

Ensure there are no changes that may adversely

affect equipment performance.

Semiannually Inspect batteries for corrosion or leakage. Verify

that the battery connections are tight and secure.

Clean the connections, if required. Replace

batteries every 5 years, or sooner if conditions

warrant.

it trouble signals Semiannually Ensure there are no changes that may adversely

affect equipment performance.

Emergency voice/alarm

communication equipment

Semiannually Inspect the equipment for any visible signs of

damage or other changes that may adversely

affect performance.

Semiannually Inspect the equipment for any visible signs of

damage or other changes that may adversely

affect performance.

Semiannually Inspect the equipment for any visible signs of

damage or other changes that may adversely

affect performance.

Electromechanical releasing

devices

Semiannually Ensure there are no changes that may adversely

affect equipment performance.

Fire extinguishing systems or

suppression systems

Semiannually Ensure there are no changes that may adversely

affect equipment performance.

Semiannually Inspect the equipment for any visible signs of

damage or other changes that may adversely

affect performance.

Semiannually Inspect the equipment for any visible signs of

damage or other changes that may adversely

affect performance. Clean if necessary.

Loading...

Loading...