5-62

F codes

E codes

C codes

P codes

H codes

A codes

b codes

r codes

J codes

d codes

U codes

y codes

Chap. 5 FUNCTION CODES

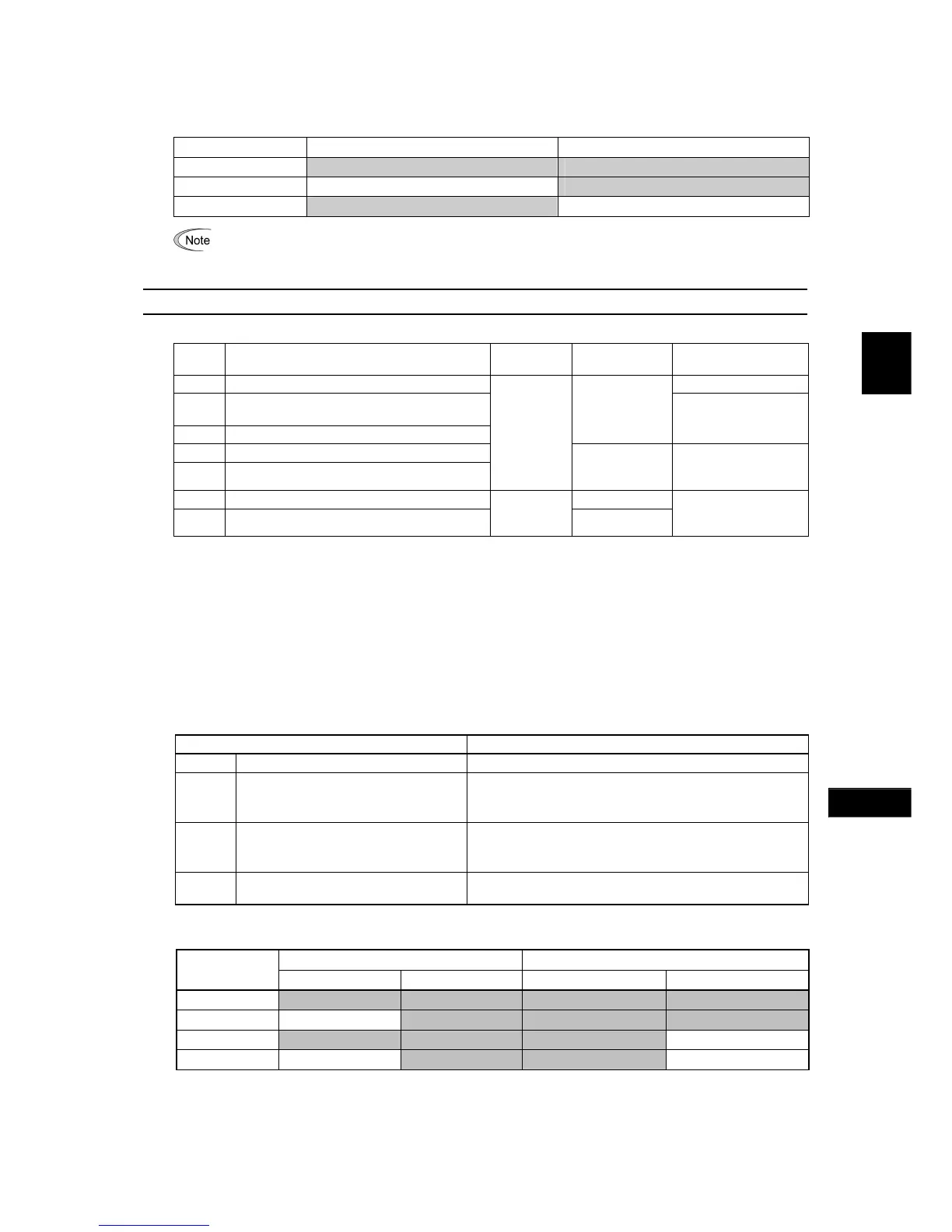

Torque limiter (Operating conditions) (H73)

H73 specifies whether the torque limiter is enabled or disabled during acceleration/deceleration and running at constant

speed.

Data for H73 During accelerating/decelerating During running at constant speed

0 Enable Enable

1 Disable Enable

2 Enable Disable

The torque limiter and current limiter are very similar function each other. If both are activated concurrently,

they may conflict each other and cause hunting in the system. Avoid concurrent activation of these limiters.

F42 Drive Control Selection 1 H68 (Slip Compensation 1 (Operating conditions))

F42 specifies the motor drive control.

Data for

F42

Drive control Basic control Speed feedback Speed control

0 V/f control with slip compensation inactive Frequency control

1

Dynamic torque vector control

(with slip compensation and auto torque boost)

2 V/f control with slip compensation active

Disable

Frequency control

with slip compensation

3 V/f control with speed sensor

4 Dynamic torque vector control with speed sensor

V/f control

Enable

Frequency control

with automatic speed

regulator (ASR)

5 Vector control without speed sensor

Estimated speed

6 Vector control with speed sensor

Vector control

Enable

Speed control

with automatic speed

regulator (ASR)

V/f control with slip compensation inactive

Under this control, the inverter controls a motor with the voltage and frequency according to the V/f pattern specified

by function codes. This control disables all automatically controlled features such as the slip compensation, so no

unpredictable output fluctuation, enabling stable operation with constant output frequency.

V/f control with slip compensation active

Applying any load to an induction motor causes a rotational slip due to the motor characteristics, decreasing the motor

rotation. The inverter’s slip compensation function first presumes the slip value of the motor based on the motor torque

generated and raises the output frequency to compensate for the decrease in motor rotation. This prevents the motor

from decreasing the rotation due to the slip.

That is, this function is effective for improving the motor speed control accuracy.

Function code Operation

P12 Rated slip frequency Specify the rated slip frequency.

P09 Slip compensation gain for driving

Adjust the slip compensation amount for driving.

Slip compensation amount for driving =

Rated slip x Slip compensation gain for driving

P11 Slip compensation gain for braking

Adjust the slip compensation amount for braking.

Slip compensation amount for braking =

Rated slip x Slip compensation gain for braking

P10 Slip compensation response time

Specify the slip compensation response time.

Basically, there is no need to modify the default setting.

To improve the accuracy of slip compensation, perform auto-tuning.

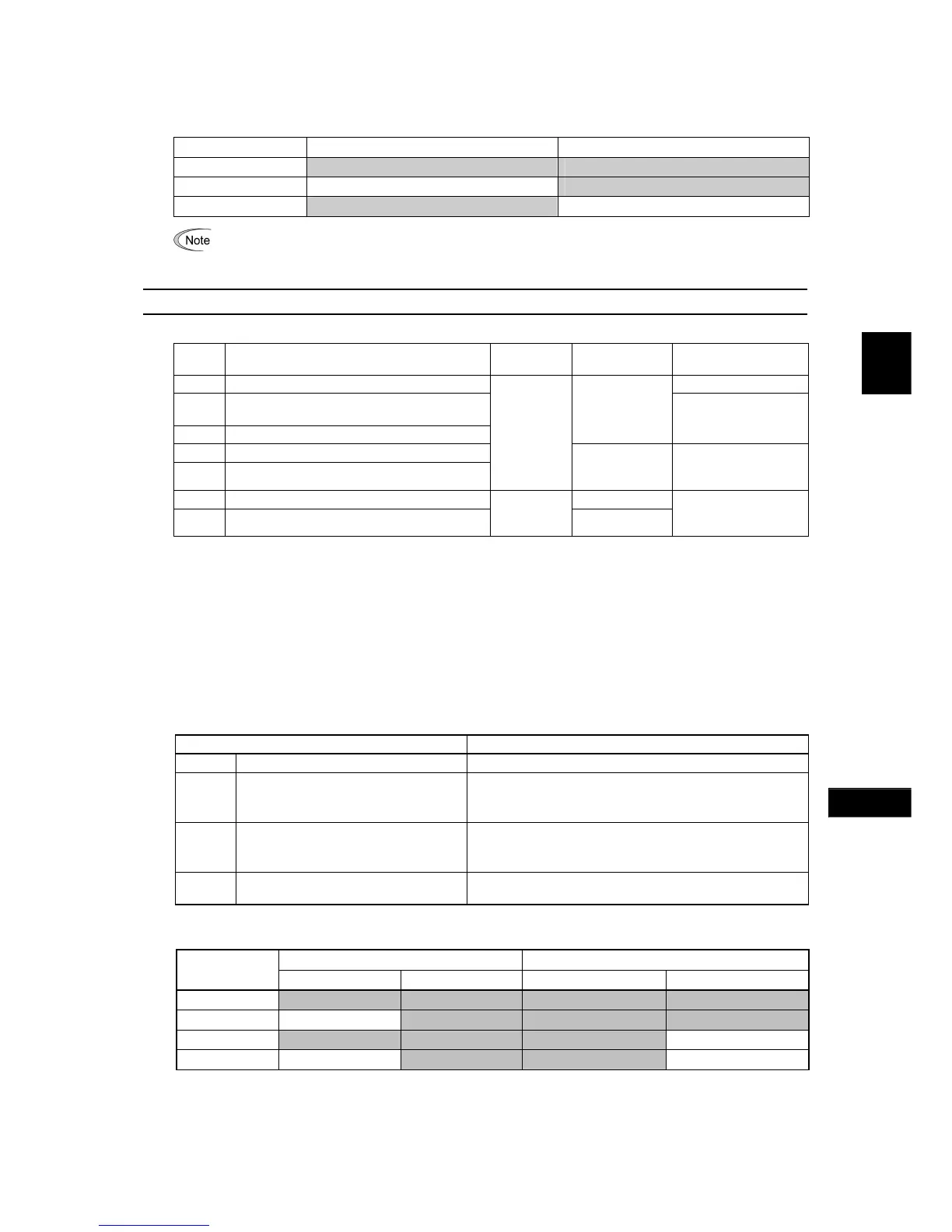

H68 enables or disables the slip compensation function according to the motor driving conditions.

Motor driving conditions Motor driving frequency zone

Data for H68

Accel/Decel

Constant speed Base frequency or below Above the base frequency

0 Enable Enable Enable Enable

1 Disable Enable Enable Enable

2 Enable Enable Enable Disable

3 Disable Enable Enable Disable

Loading...

Loading...