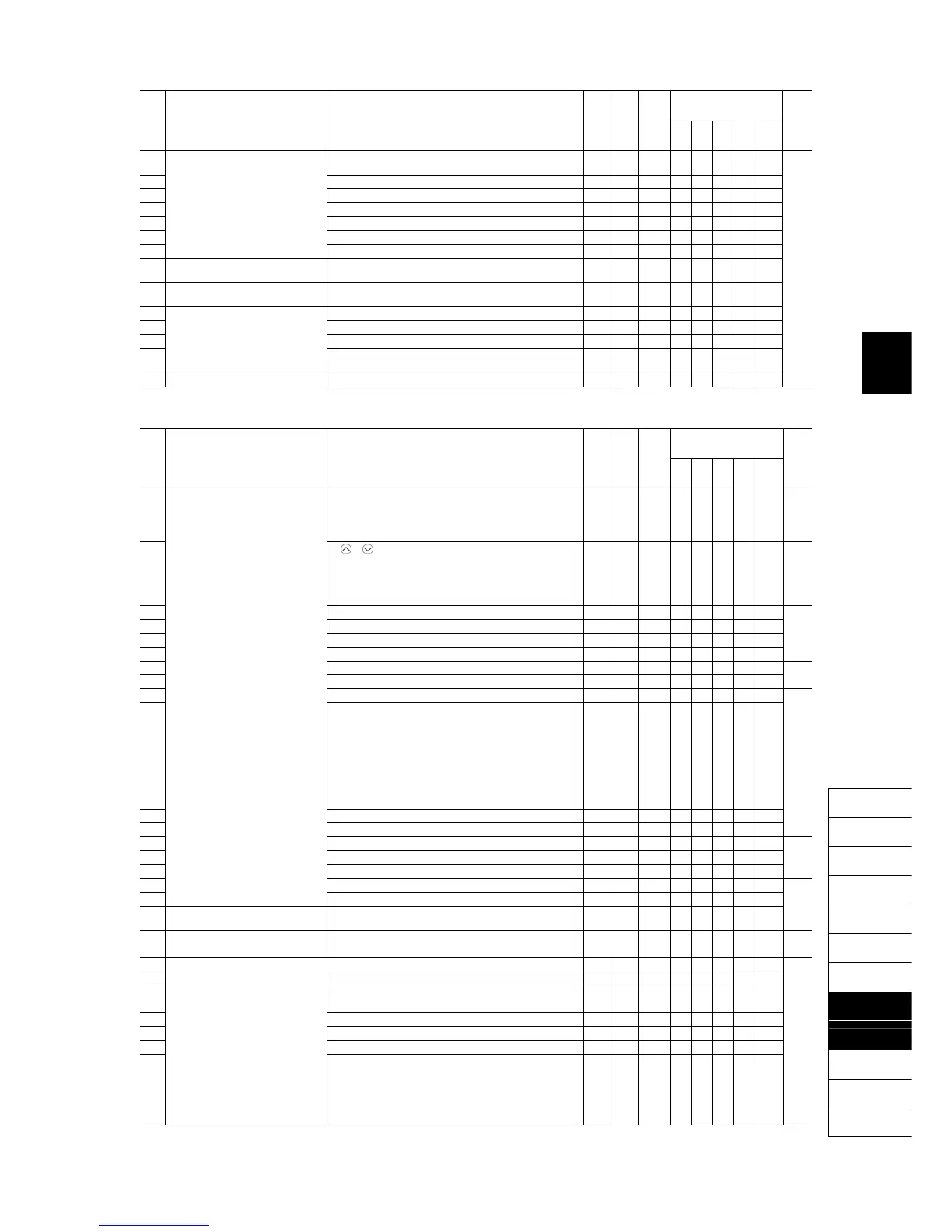

5-18

Chap. 5 FUNCTION CODES

F codes

E codes

C codes

P codes

H codes

A codes

b codes

r codes

J codes

d codes

U codes

y codes

Drive control

Code Name Data setting range

Change when

running

Data copying

Default

setting

V/f

PG

V/f

w/o

PG

w/

PG

Torque

control

Refer

to

page:

r43 Speed Control 4

(Speed command filter)

0.000 to 5.000 s Y Y 0.020 N Y Y Y N ―

r44 (Speed detection filter) 0.000 to 0.100 s Y* Y 0.005 N Y Y Y N

r45 P (Gain) 0.1 to 200.0 times Y* Y 10.0 N Y Y Y N

r46 I (Integral time) 0.001 to 9.999 s Y* Y 0.100 N Y Y Y N

r48 (Output filter) 0.000 to 0.100 s Y Y 0.002 N Y Y Y N

r49 (Notch filter resonance frequency) 1 to 200 Hz Y Y 200 N N N Y N

r50 (Notch filter attenuation level) 0 to 20 dB Y Y 0 N N N Y N

r51 Cumulative Motor Run Time 4 0 to 9999 (The cumulative run time can be modified or reset

in units of 10 hours.)

N N - Y Y Y Y Y

r52 Startup Counter for Motor 4 Indication of cumulative startup count

0000 to FFFF (hex.)

Y N - Y Y Y Y Y

r53 Motor 4 (%X correction factor 1) 0% to 300% Y Y1 Y2 100 Y Y Y Y Y

r54 (%X correction factor 2) 0% to 300% Y Y1 Y2 100 Y Y Y Y Y

r55 (Torque current under vector control) 0.00 to 2000 A N Y1 Y2 *7 N N Y Y Y

r56 (Induced voltage factor under

vector control)

50 to 100 N Y1 Y2 85 N N Y Y Y

r57 Reserved *9 0.000 to 20.000 s Y Y1 Y2 *7 - - - - -

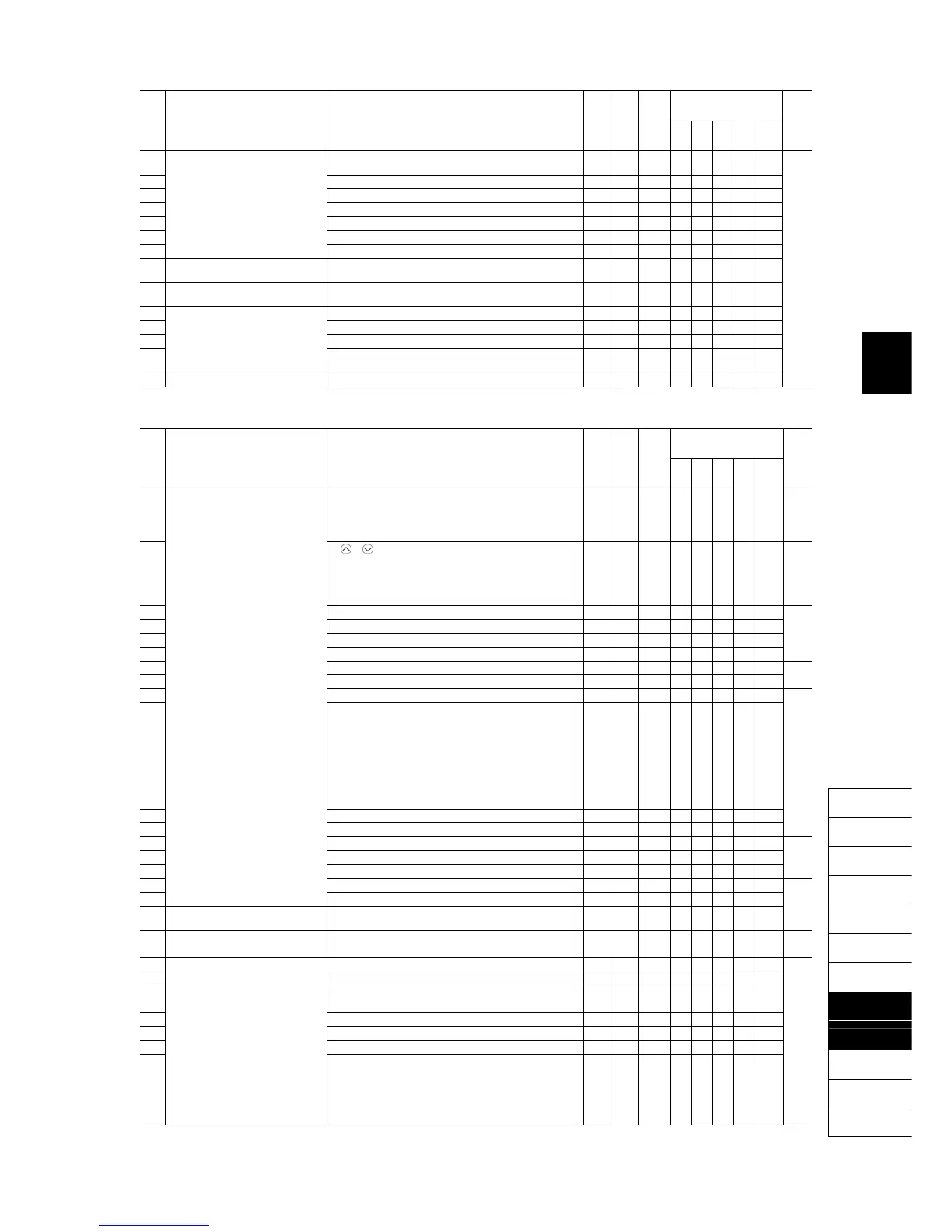

J codes: Application Functions 1

Drive control

Code Name Data setting range

Change when

running

Data copying

Default

setting

V/f

PG

V/f

w/o

PG

w/

PG

Torque

control

Refer

to

page:

J01 PID Control (Mode selection) 0: Disable

1: Enable (Process control, normal operation)

2: Enable (Process control, inverse operation)

3: Enable (Dancer control)

N Y 0 Y Y Y Y N 5-120

J02 (Remote command SV) 0:

/

keys on keypad

1: PID command 1

(Analog input terminals [12], [C1], and [V2])

3: UP/DOWN

4: Command via communications link

N Y 0 Y Y Y Y N 5-121

J03 P (Gain) 0.000 to 30.000 times Y Y 0.100 Y Y Y Y N 5-124

J04 I (Integral time) 0.0 to 3600.0 s Y Y 0.0 Y Y Y Y N

J05 D (Differential time) 0.00 to 600.00 s Y Y 0.00 Y Y Y Y N

J06 (Feedback filter) 0.0 to 900.0 s Y Y 0.5 Y Y Y Y N

J08 (Pressurization starting frequency) 0.0 to 500.0 Hz Y Y 0.0 Y Y Y Y N 5-126

J09 (Pressurizing time) 0 to 60 s Y Y 0 Y Y Y Y N

J10 (Anti reset windup) 0% to 200% Y Y 200 Y Y Y Y N 5-127

J11 (Select alarm output)

0: Absolute-value alarm

1: Absolute-value alarm (with Hold)

2: Absolute-value alarm (with Latch)

3: Absolute-value alarm (with Hold and Latch)

4: Deviation alarm

5: Deviation alarm (with Hold)

6: Deviation alarm (with Latch)

7: Deviation alarm (with Hold and Latch)

Y Y 0 Y Y Y Y N

J12 (Upper level alarm (AH)) -100% to 100% Y Y 100 Y Y Y Y N

J13 (Lower level alarm (AL)) -100% to 100% Y Y 0 Y Y Y Y N

J15 (Stop frequency for slow flowrate) 0.0: Disable; 1.0 to 500.0 Hz Y Y 0.0 Y Y Y Y N 5-126

J16 (Slow flowrate level stop latency) 0 to 60 s Y Y 30 Y Y Y Y N 5-128

J17 (Starting frequency) 0.0 to 500.0 Hz Y Y 0.0 Y Y Y Y N

J18 (Upper limit of PID process output) -150% to 150%; 999: Depends on setting of F15 Y Y 999 Y Y Y Y N 5-128

J19 (Lower limit of PID process output) -150% to 150%; 999: Depends on setting of F16 Y Y 999 Y Y Y Y N

J21 Dew Condensation Prevention

(Duty)

1% to 50% Y Y 1 Y Y Y Y Y

J22 Commercial Power Switching

Sequence

0: Keep inverter operation (Stop due to alarm)

1: Automatically switch to commercial-power operation

N Y 0 Y Y N N Y 5-67

5-129

J56 PID Control (Speed command filter) 0.00 to 5.00 s Y Y 0.10 Y Y Y Y N 5-129

J57 (Dancer reference position) -100% to 0% to 100% Y Y 0 Y Y Y Y N

J58 (Detection width of dancer

position deviation)

0: Disable switching PID constant

1% to 100% (Manually set value)

Y Y 0 Y Y Y Y N

J59 P (Gain) 2 0.000 to 30.000 times Y Y 0.100 Y Y Y Y N

J60 I (Integral time) 2 0.0 to 3600.0 s Y Y 0.0 Y Y Y Y N

J61 D (Differential time) 3 0.00 to 600.00 s Y Y 0.00 Y Y Y Y N

J62 (PID control block selection) 0 to 3

bit 0: PID output polarity

0: Plus (add), 1: Minus (subtract)

bit 1: Select compensation factor for PID output

0 = Ratio (relative to the main setting)

1 = Speed command (relative to maximum frequency)

N Y 0 Y Y Y Y N

*7 The motor parameters are automatically set, depending upon the inverter's capacity and shipping destination. See Table C.

*9 These function codes are reserved for particular manufacturers. Unless otherwise specified, do not access these function codes.

Loading...

Loading...