5-36

F codes

E codes

C codes

P codes

H codes

A codes

b codes

r codes

J codes

d codes

U codes

y codes

Chap. 5 FUNCTION CODES

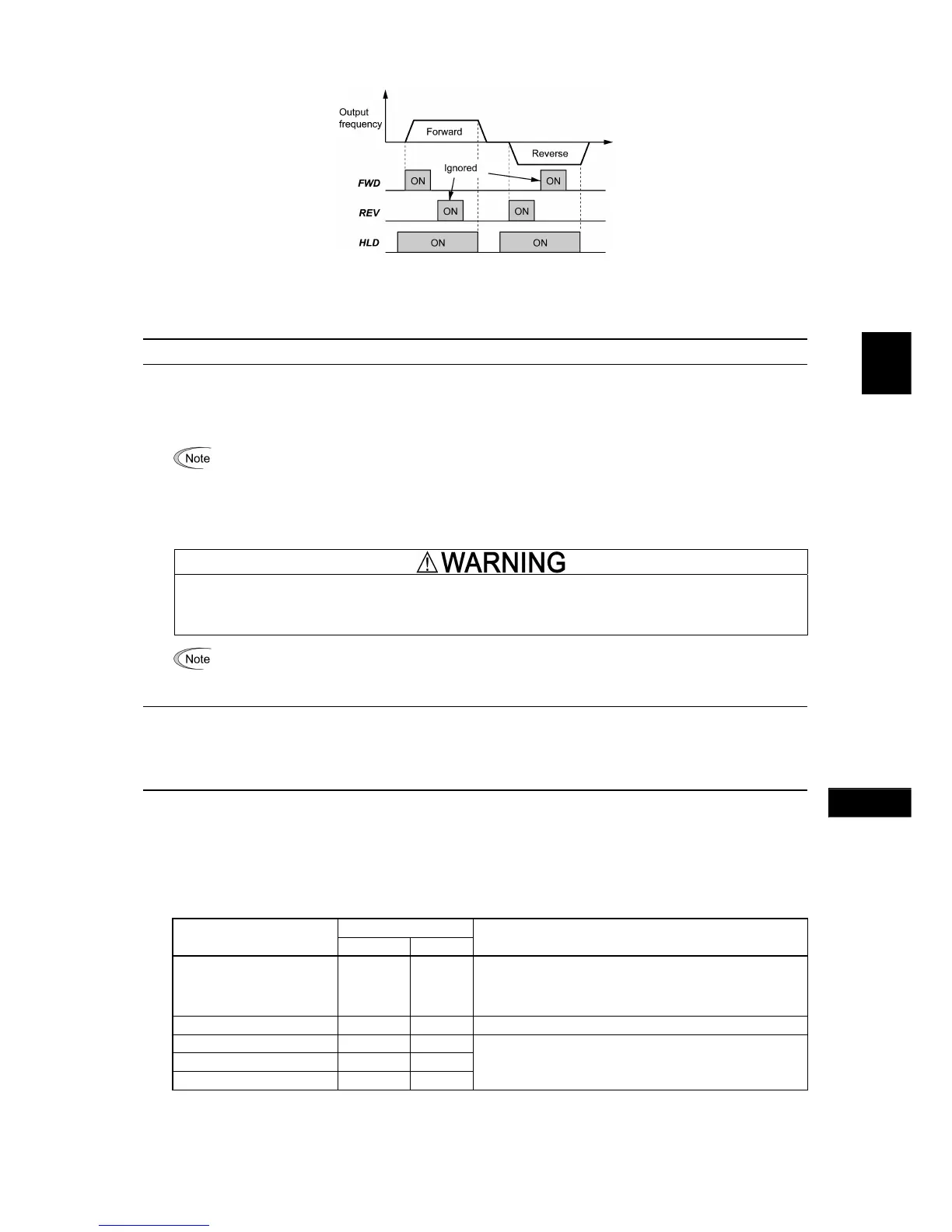

In addition to the run command sources described above, higher priority command sources including remote and local

mode (see Section 7.3.6) and communications link are provided. For details, refer to the block diagrams in Chapter 6 in

FRENIC-MEGA User's Manual.

F03 Maximum Frequency 1

F03 specifies the maximum frequency to limit the output frequency. Specifying the maximum frequency exceeding the

rating of the equipment driven by the inverter may cause damage or a dangerous situation. Make sure that the maximum

frequency setting matches the equipment rating.

- Data setting range: 25.0 to 500.0 (Hz)

• For MD- and LD-mode inverters, set the maximum frequency at 120 Hz or below.

• Under vector control with speed sensor, set the maximum frequency at 200 Hz or below, and under vecto

control without speed sensor, at 120 Hz or below.

• If a setting exceeding the maximum setting value (e.g., 500 Hz) is made, the reference speed and analog

output (FMA) will be based on the full scale/reference value (10V/500 Hz). However, the frequency is

internally limited. Even if 10 V is inputted, the frequency 500 Hz will be internally limited to 200 Hz.

The inverter can easily accept high-speed operation. When changing the speed setting, carefully check the

specifications of motors or equipment beforehand.

Otherwise injuries could occur.

Modifying F03 data to allow a higher reference frequency requires also changing F15 data specifying a

frequency limiter (high).

F04 to F05

F06

Base Frequency 1, Rated Voltage at Base Frequency 1

Maximum Output Voltage 1

H50, H51 (Non-linear V/f Pattern 1 (Frequency and Voltage))

H52, H53 (Non-linear V/f Pattern 2 (Frequency and Voltage))

H65, H66 (Non-linear V/f Pattern 3 (Frequency and Voltage))

These function codes specify the base frequency and the voltage at the base frequency essentially required for running

the motor properly. If combined with the related function codes H50 through H53, H65 and H66, these function codes

may profile the non-linear V/f pattern by specifying increase or decrease in voltage at any point on the V/f pattern.

The following description includes setups required for the non-linear V/f pattern.

At high frequencies, the motor impedance may increase, resulting in an insufficient output voltage and a decrease in

output torque. To prevent this problem, use F06 (Maximum Output Voltage 1) to increase the voltage. Note, however,

that the inverter cannot output voltage exceeding its input power voltage.

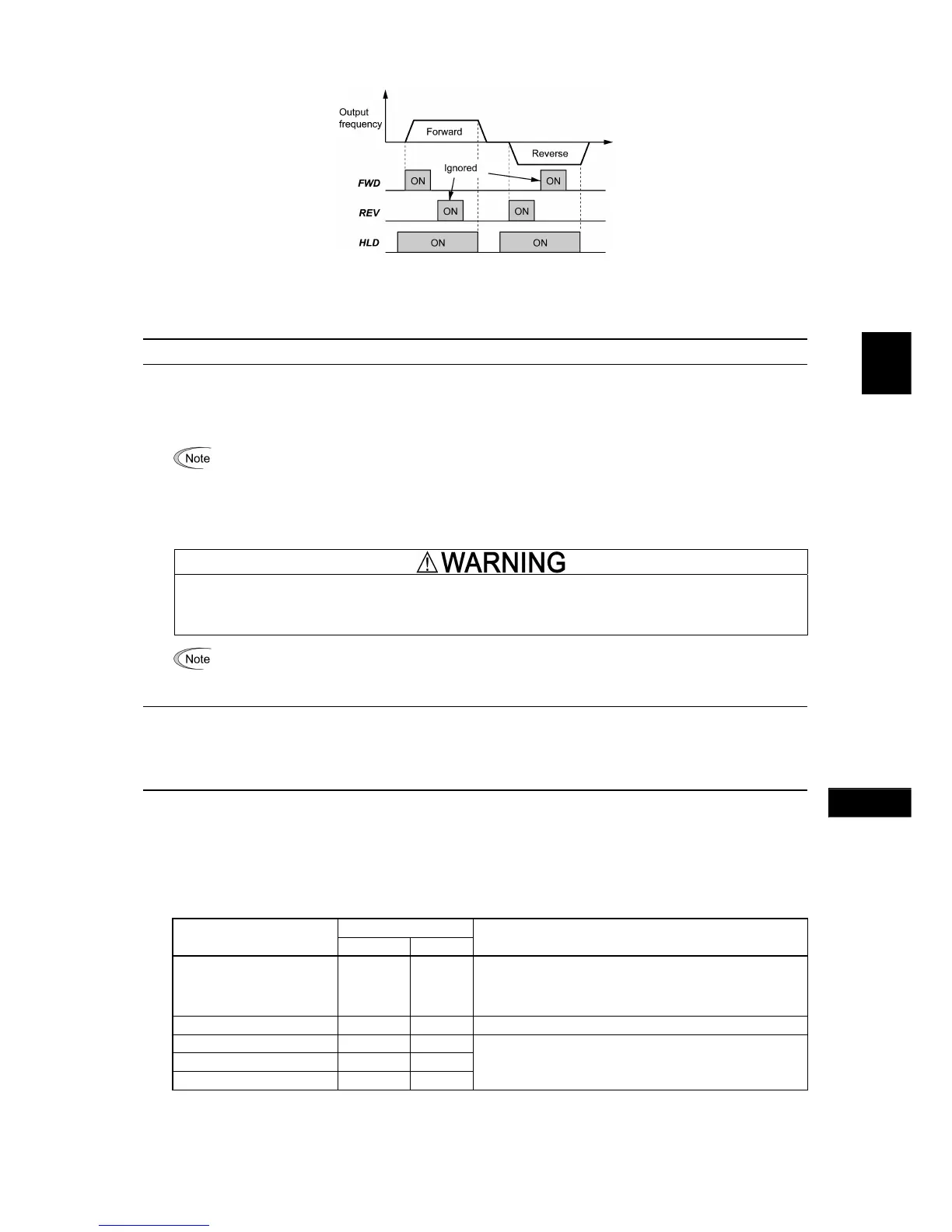

Function code

V/f point

Frequency Voltage

Remarks

Maximum frequency F03 F06

The setting of the maximum output voltage is disabled

when the auto torque boost, torque vector control, vector

control without speed sensor, or vector control with speed

sensor is selected.

Base frequency F04 F05

Non-linear V/f pattern 3 H65 H66

Non-linear V/f pattern 2 H52 H53

Non-linear V/f pattern 1 H50 H51

Disabled when the auto torque boost, torque vector

control, vector control without speed sensor, or vector

control with speed sensor is selected.

Loading...

Loading...