6-10

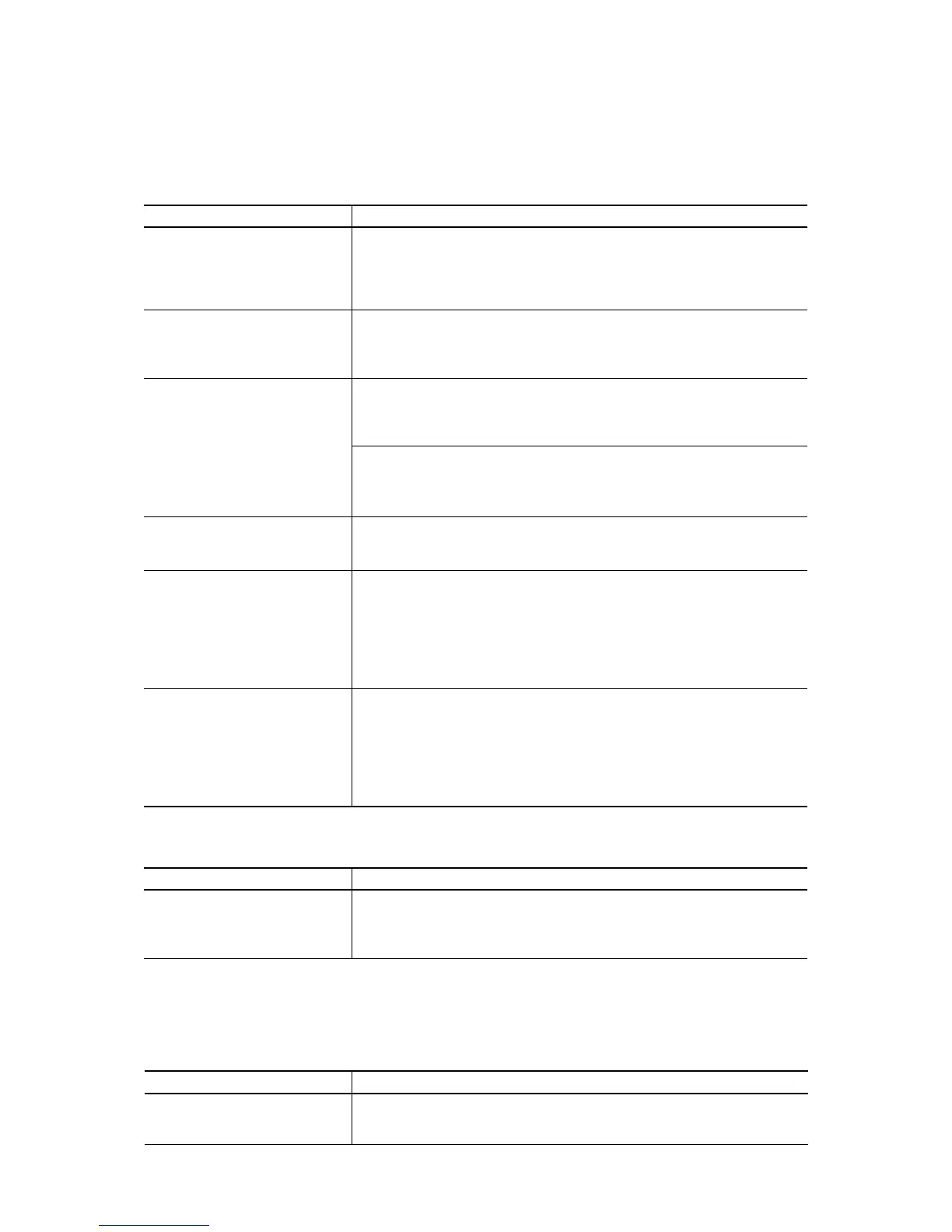

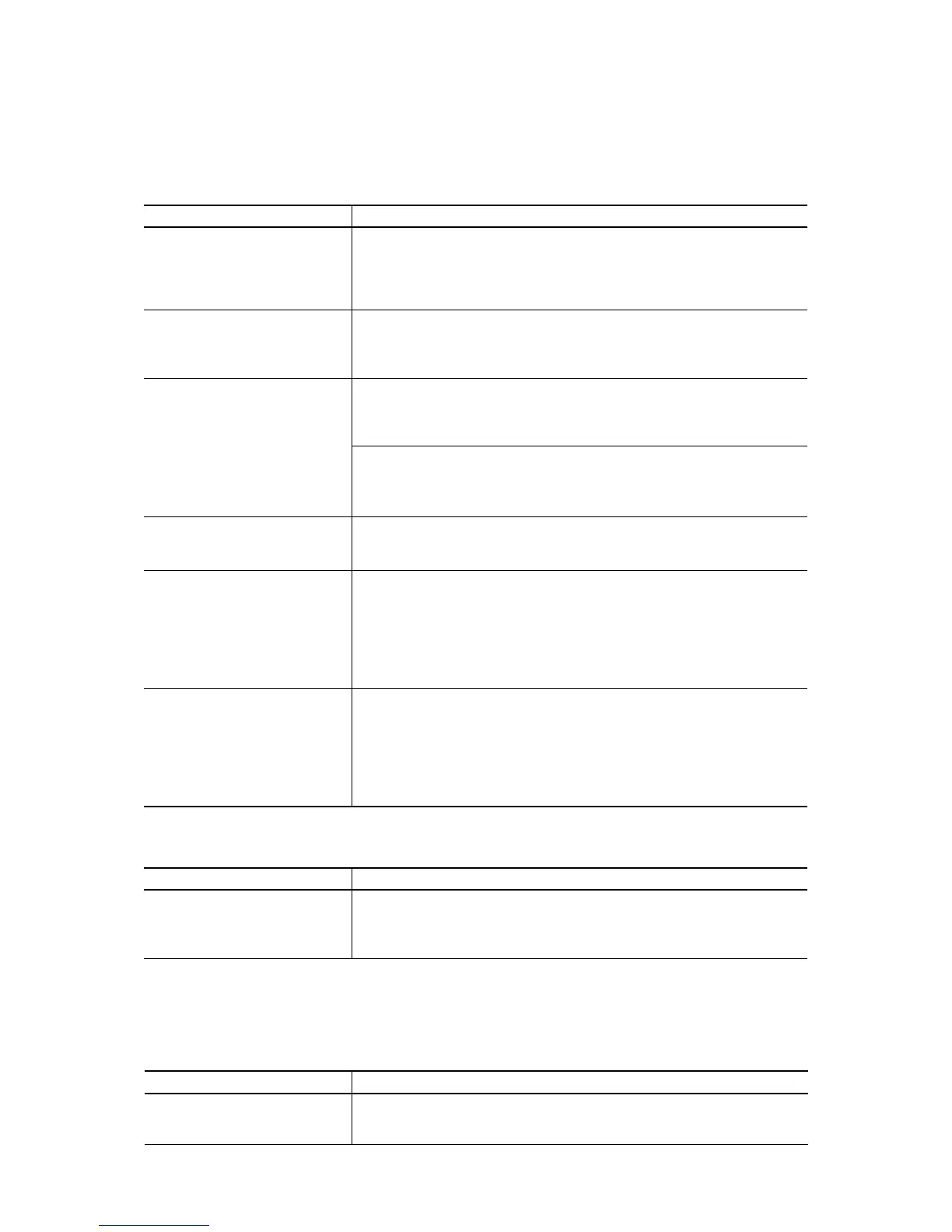

6.4 If an Alarm Code Appears on the LED Monitor

[ 1 ]

0cn

Instantaneous overcurrent

Problem The inverter momentary output current exceeded the overcurrent level.

0c1

Overcurrent occurred during acceleration.

0c2

Overcurrent occurred during deceleration.

0c3

Overcurrent occurred during running at a constant speed.

Possible Causes What to Check and Suggested Measures

(1) The inverter output lines were

short-circuited.

Disconnect the wiring from the inverter output terminals ([U], [V] and [W]) and

measure the interphase resistance of the motor wiring. Check if the resistance is too

low.

Î Remove the short-circuited part (including replacement of the wires, relay

terminals and motor).

(2) Ground faults have occurred at

the inverter output lines.

Disconnect the wiring from the output terminals ([U], [V] and [W]) and perform a

Megger test.

Î Remove the grounded parts (including replacement of the wires, relay terminals

and motor).

Measure the motor current with a measuring device to trace the current trend. Then,

use this data to judge if the trend is over the calculated load value for your system

design.

ÎIf the load is too heavy, reduce it or increase the inverter capacity.

(3) Overload.

Trace the current trend and check if there are any sudden changes in the current.

Î If there are any sudden changes, make the load fluctuation smaller or increase

the inverter capacity.

Î Enable instantaneous overcurrent limiting (H12 = 1).

(4) Excessive torque boost

specified.

(when F37* = 0, 1, 3, or 4)

Check whether decreasing the torque boost (F09*) decreases the output current but

does not stall the motor.

Î If no stall occurs, decrease the torque boost (F09*).

(5) The acceleration/ deceleration

time was too short.

Check that the motor generates enough torque required during

acceleration/deceleration. That torque is calculated from the moment of inertia for

the load and the acceleration/deceleration time.

Î Increase the acceleration/deceleration time (F07, F08, E10 through E15, and

H56).

Î Enable the current limiter (F43) and torque limiter (F40, F41, E16, and E17).

Î Increase the inverter capacity.

(6) Malfunction caused by noise. Check if noise control measures are appropriate (e.g., correct grounding and routing

of control and main circuit wires).

Î Implement noise control measures. For details, refer to the FRENIC-MEGA

User's Manual, "Appendix A."

Î Enable the Auto-reset (H04).

Î Connect a surge absorber to magnetic contactor's coils or other solenoids (if

any) causing noise.

[ 2 ]

ef

Ground fault

Problem A ground fault current flew from the output terminal of the inverter.

Possible Causes What to Check and Suggested Measures

(1) Inverter output terminal(s)

grounded (ground fault).

Disconnect the wiring from the output terminals ([U], [V], and [W]) and perform a

Megger test.

Î Remove the grounded parts (including replacement of the wires, relay terminals

and motor).

[ 3 ]

0un

Overvoltage

Problem The DC link bus voltage was over the detection level of overvoltage.

0u1

Overvoltage occurred during acceleration.

0u2

Overvoltage occurred during deceleration.

0u3

Overvoltage occurred during running at constant speed.

Possible Causes What to Check and Suggested Measures

(1) The power supply voltage

exceeded the inverter's

specification range.

Measure the input voltage.

Î Decrease the voltage to within the specified range.

Loading...

Loading...