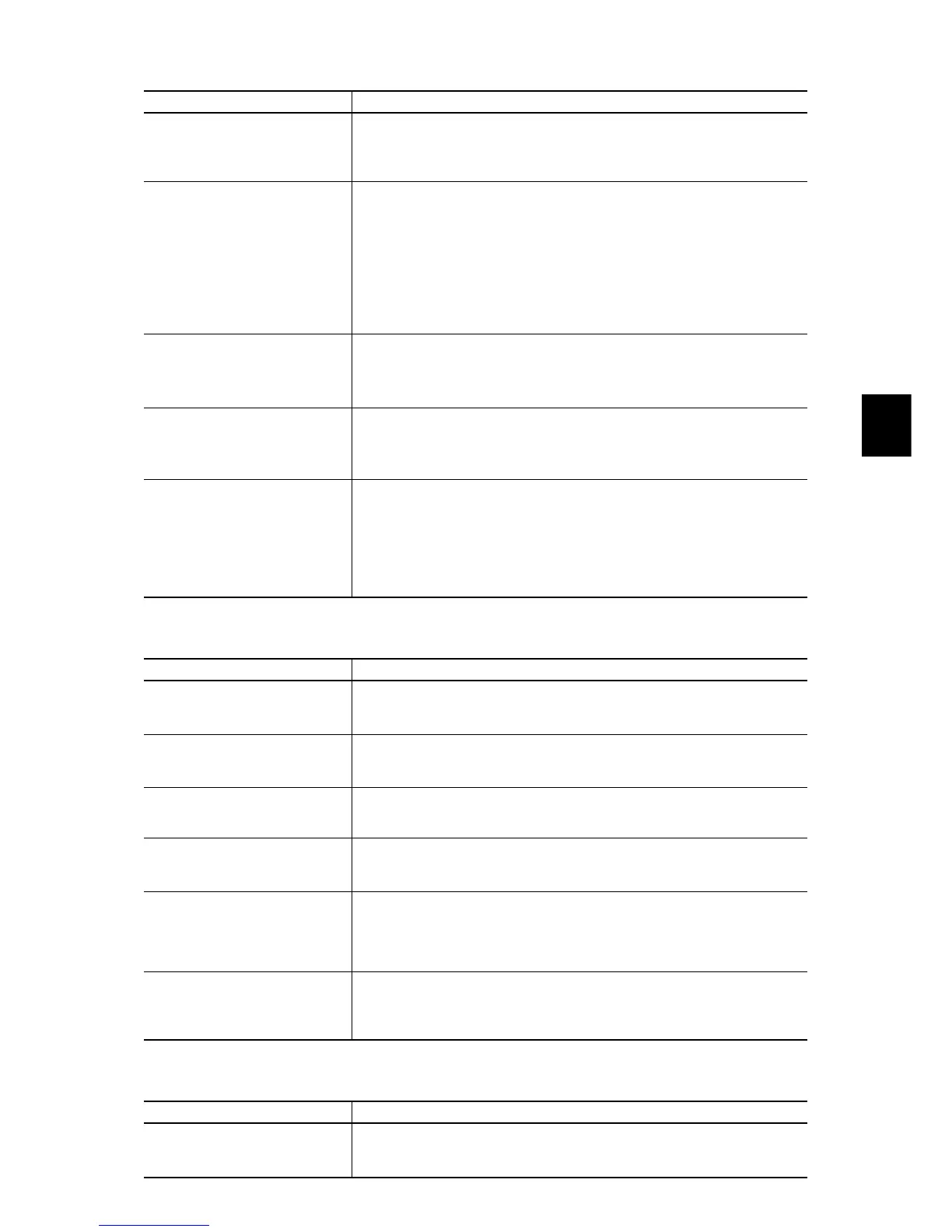

6-11

Chap. 6 TROUBLESHOOTING

Possible Causes What to Check and Suggested Measures

(2) A surge current entered the

input power supply.

In the same power line, if a phase-advancing capacitor is turned ON/OFF or a

thyristor converter is activated, a surge (momentary large increase in the voltage or

current) may be caused in the input power.

Î Install a DC reactor.

(3) The deceleration time was too

short for the moment of inertia

for load.

Recalculate the deceleration torque based on the moment of inertia for the load and

the deceleration time.

Î Increase the deceleration time (F08, E11, E13, E15, and H56).

Î Enable the automatic deceleration (anti-regenerative control) (H69), or

deceleration characteristics (H71).

Î Enable torque limiter (F40, F41, E16, E17, and H73).

Î Set the rated voltage (at base frequency) (F05*) to "0" to improve the braking

capability.

Î Consider the use of a braking resistor.

(4) The acceleration time was too

short.

Check if the overvoltage alarm occurs after rapid acceleration.

Î Increase the acceleration time (F07, E10, E12, and E14).

Î Select the S-curve pattern (H07).

Î Consider the use of a braking resistor.

(5) Braking load was too heavy. Compare the braking torque of the load with that of the inverter.

Î Set the rated voltage (at base frequency) (F05*) to "0" to improve the braking

capability.

Î Consider the use of a braking resistor.

(6) Malfunction caused by noise. Check if the DC link bus voltage was below the protective level when the

overvoltage alarm occurred.

Î Implement noise control measures. For details, refer to the FRENIC-MEGA

User's Manual, "Appendix A."

Î Enable the auto-reset (H04).

Î Connect a surge absorber to magnetic contactor's coils or other solenoids (if

any) causing noise.

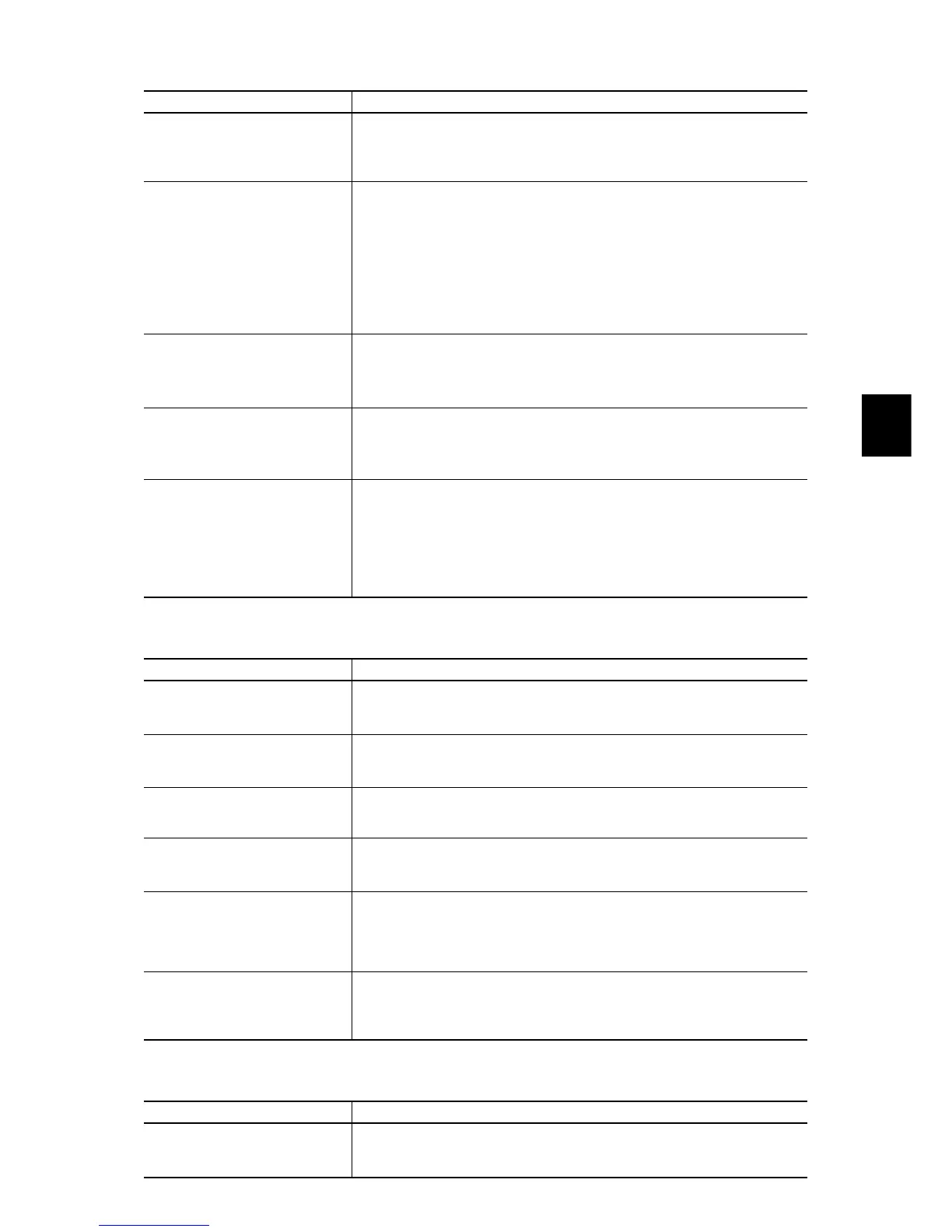

[ 4 ]

lu

Undervoltage

Problem DC link bus voltage has dropped below the undervoltage detection level.

Possible Causes What to Check and Suggested Measures

(1) A momentary power failure

occurred.

Î Release the alarm.

Î If you want to restart running the motor without treating this condition as an

alarm, set F14 to "3," "4," or "5," depending on the load type.

(2) The power to the inverter was

switched back to ON too soon

(when F14 = 1).

Check if the power to the inverter was switched back to ON while the control power

was still alive. (Check whether the LEDs on the keypad light.)

Î Turn the power ON again after all LEDs on the keypad go off.

(3) The power supply voltage did

not reach the inverter's

specification range.

Measure the input voltage.

Î Increase the voltage to within the specified range.

(4) Peripheral equipment for the

power circuit malfunctioned, or

the connection was incorrect.

Measure the input voltage to find which peripheral equipment malfunctioned or

which connection is incorrect.

Î Replace any faulty peripheral equipment, or correct any incorrect connections.

(5) Any other loads connected to

the same power supply has

required a large starting

current, causing a temporary

voltage drop.

Measure the input voltage and check the voltage fluctuation.

Î Reconsider the power supply system configuration.

(6) Inverter's inrush current caused

the power voltage drop because

the power supply transformer

capacity was insufficient.

Check if the alarm occurs when a molded case circuit breaker (MCCB),

residual-current-operated protective device (RCD)/earth leakage circuit breaker

(ELCB) (with overcurrent protection) or magnetic contactor (MC) is turned ON.

ÎReconsider the capacity of the power supply transformer.

[ 5 ]

lin

Input phase loss

Problem Input phase loss occurred, or interphase voltage unbalance rate was large.

Possible Causes What to Check and Suggested Measures

(1) Breaks in wiring to the main

power input terminals.

Measure the input voltage.

Î Repair or replace the main circuit power input wires or input devices (MCCB,

MC, etc.).

Loading...

Loading...