3-3

Chap. 3 OPERATION USING THE KEYPAD

3.3 Running Mode

3.3.1 Monitoring the running status

In Running mode, the fourteen items listed below can be monitored. Immediately after the inverter is turned ON, the monitor

item specified by function code E43 is displayed. Press the

key to switch between these monitor items.

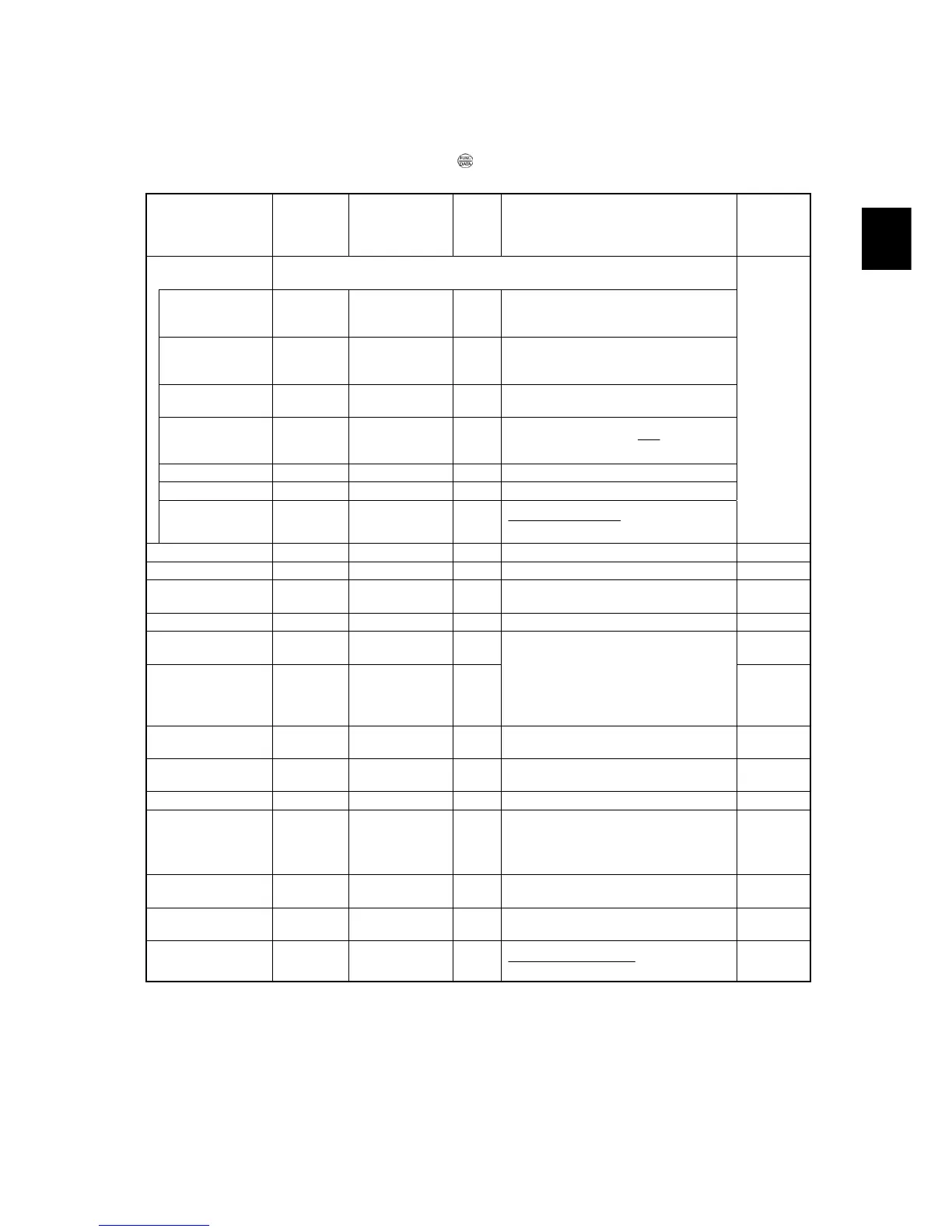

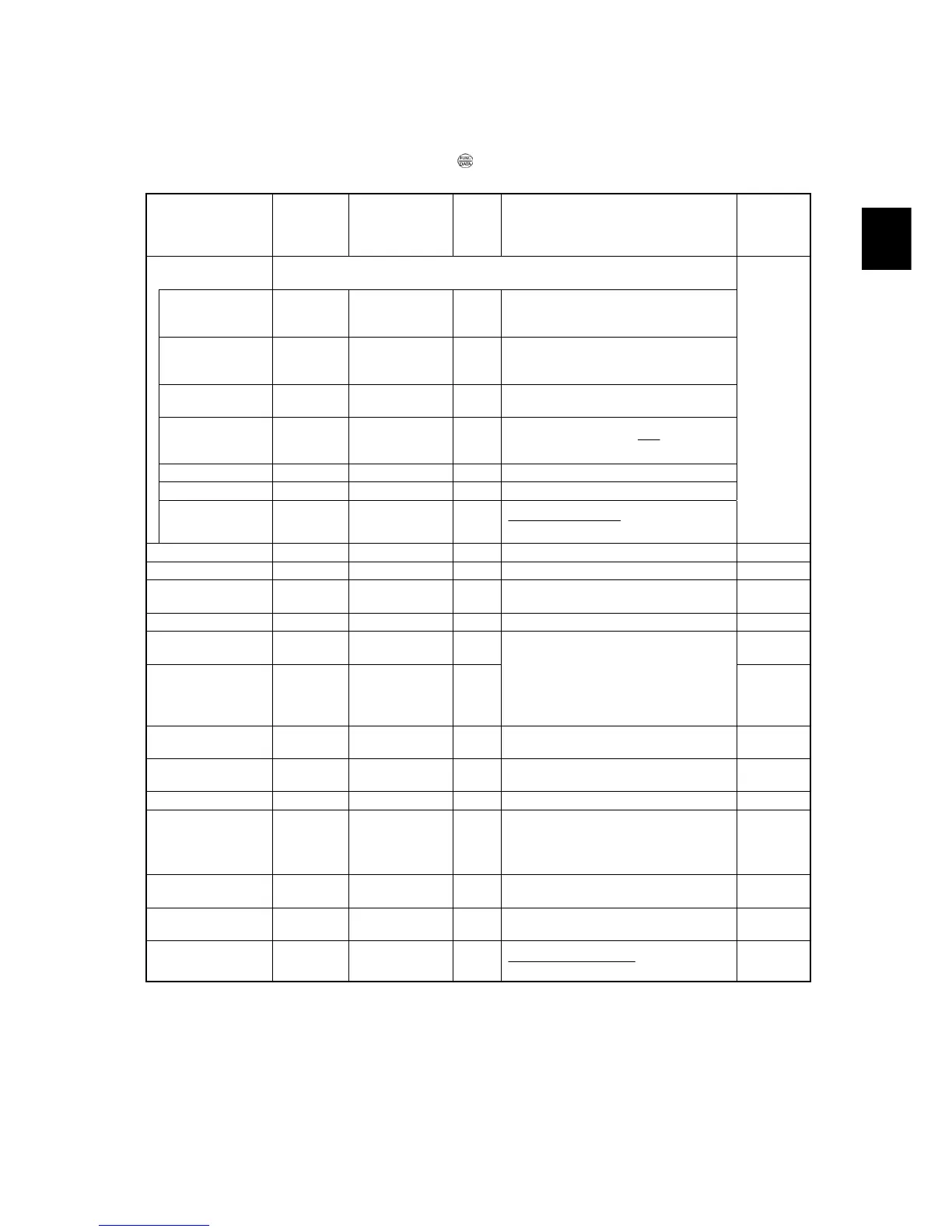

Table 3.3 Monitoring Items

Monitor items

Display

sample on the

LED monitor

*

1

LED indicator

: ON, : OFF

Unit Meaning of displayed value

Function

code data

for E43

Speed monitor

Function code E48 specifies what to be displayed on the LED monitor and LED

indicators.

0

Output frequency 1

(before slip

compensation)

5*00

Hz A kW Hz Frequency actually being output (E48 = 0)

Output frequency 2

(after slip

compensation)

5*00

Hz A kW Hz Frequency actually being output (E48 = 1)

Reference

frequency

5*00

Hz A kW Hz Reference frequency being set (E48 = 2)

Motor speed

1500

Hz A kW r/min

P01

120

× (Hz)frequency Output

(E48 = 3)

Load shaft speed

30*0

Hz A kW r/min Output frequency (Hz) × E50 (E48 = 4)

Line speed

30*0

Hz A kW m/min Output frequency (Hz) × E50 (E48 = 5)

Speed (%)

5*0

Hz A kW %

100x

frequency Maximum

frequencyOutput

(E48 = 7)

Output current

1"34

Hz A kW A Current output from the inverter in RMS 3

Output voltage *

2

200u

Hz A kW V Voltage output from the inverter in RMS 4

Calculated torque

50

Hz A kW %

Motor output torque in %

(Calculated value)

8

Input power

1*25

Hz A kW kW Input power to the inverter 9

PID command

*

3

, *

4

1*0*

Hz A kW ― 10

PID feedback amount

*

3

, *

5

)0*

Hz A kW ―

PID command/feedback amount

transformed to that of virtual physical

value of the object to be controlled (e.g.

temperature)

Refer to function codes E40 and E41 for

details.

12

PID output *

3

, *

4

10**

Hz A kW %

PID output in % as the maximum

frequency (F03) being at 100%

14

Load factor *

6

50;

Hz A kW %

Load factor of the motor in % as the rated

output being at 100%

15

Motor output *

7

)85

Hz A kW % Motor output in kW 16

Analog input monitor

*

8

8"00

Hz A kW ―

An analog input to the inverter in a format

suitable for a desired scale.

Refer to function codes E40 and E41 for

details.

17

Torque current *

9

48

Hz A kW %

Torque current command value or

calculated torque current

23

Magnetic flux

command

*9

50

Hz A kW % Magnetic flux command value 24

Input watt-hour

10*0

Hz A kW kWh

100

(kWh)hour -Input watt

25

*1 A value exceeding 9999 cannot be displayed as is on the 4-digit LED monitor screen, so the LED monitor displays one-tenth of the actual

value with the x10 LED lit.

*2 When the LED monitor displays an output voltage, the 7-segment letter u in the lowest digit stands for the unit of the voltage "V."

*3 These PID related items appear only when the inverter drives the motor under the PID control specified by function code J01 (= 1, 2 or 3).

*4 When the LED monitor displays a PID command or its output amount, the dot (decimal point) attached to the lowest digit of the 7-segment

letter blinks.

*5 When the LED monitor displays a PID feedback amount, the dot (decimal point) attached to the lowest digit of the 7-segment letter lights.

*6 When the LED monitor displays a load factor, the 7-segment letter ; in the lowest digit stands for "%."

*7 When the LED monitor displays the motor output, the unit LED indicator "kW" blinks.

*8 The analog input monitor can appear only when the analog input monitor function is assigned to any of the analog input terminals by any of

function codes E61 to E63 (= 20).

*9

0

appears under the V/f control.

Loading...

Loading...