Chapter 11 Page no. 1782

JC-PM-A-205.fm

GE Healthcare Senographe DS

Revision 1 Service Information and Procedures Class A 2385072-16-8EN

Job Card PM A205 - Mechanical checks and lubrication

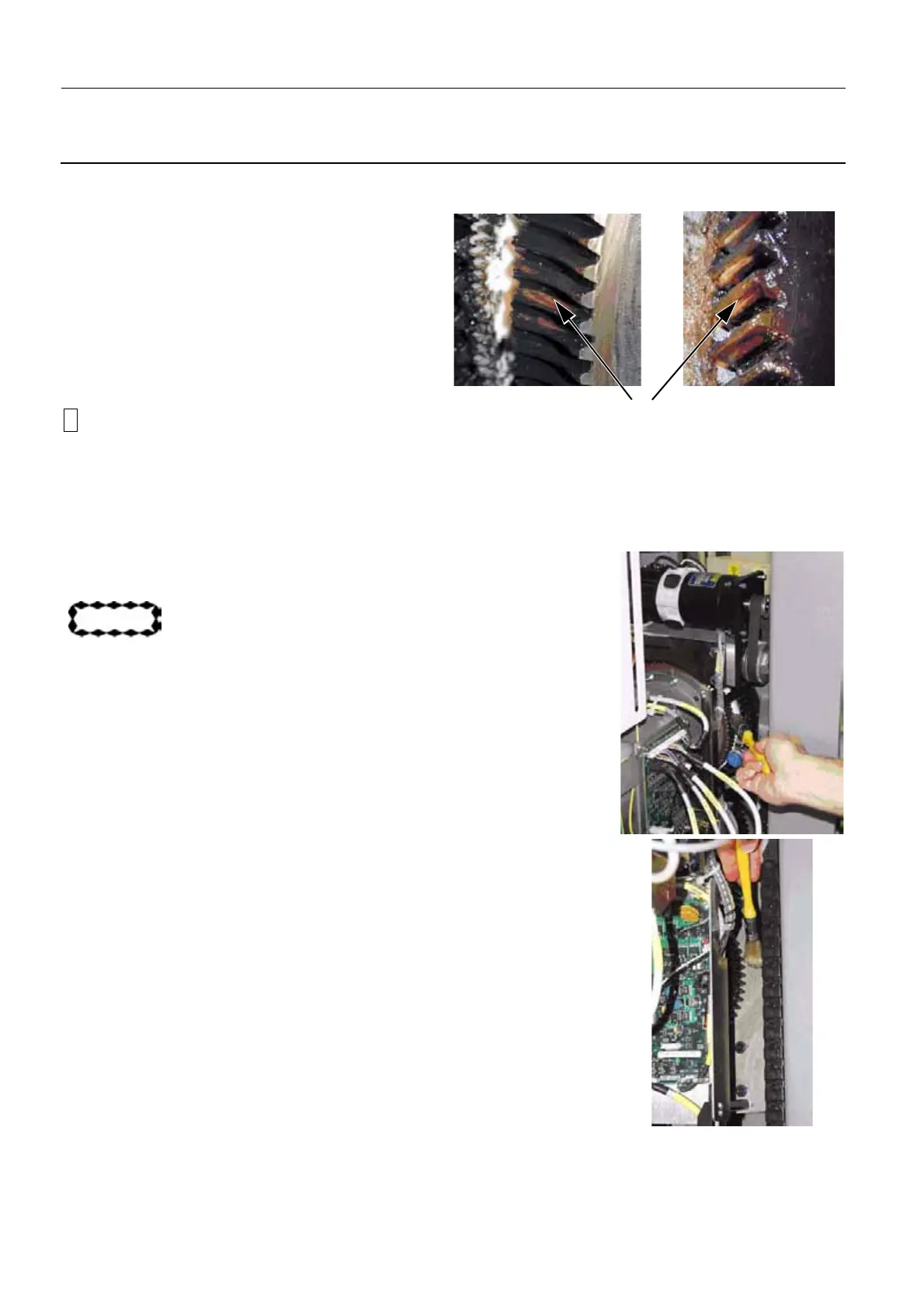

6-3-3 Locate dry surfaces

• Rotate the examination arm between -165°

and +185°.

Check for dry or partly dry surfaces as shown

here (4); this is the visible effect of incorrect

greasing

!

Notice:

Be sure to identify dry or partly dry surfaces before greasing. General greasing may not help! The

most critical areas are visible with the arm in the following positions: 0°, 45°, 135°, and 180°.

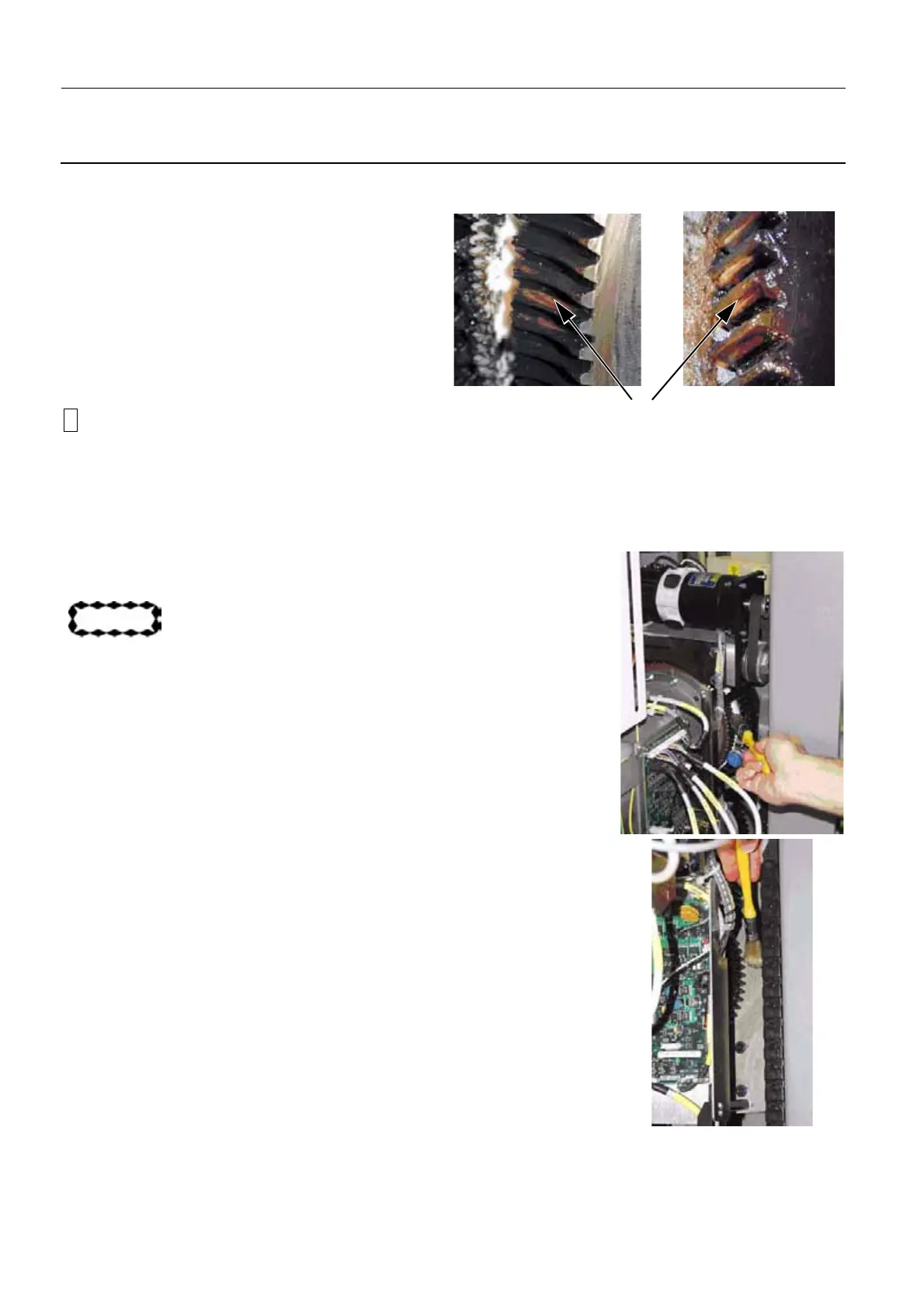

6-3-4 Greasing

• Rotate the arm between the limits of -165° and +185°, to as many

positions as required to fully inspect and grease the gears.

CAUTION

After each movement, switch OFF power while inspecting

and greasing.

• Apply a light film of Grease (for Lift and Rotation) as required to the

teeth of the worm gears and spur gears.

• Do not apply excess grease;

the quality of greasing is more important than the quantity.

• Use a brush to apply grease,

so as to avoid direct skin contact as far as possible.

• Use a suitable cloth to remove excess grease.

4

Loading...

Loading...