Chapter 9 Page no. 958

JC-DIAG-A-1000.fm

GE Healthcare Senographe DS

Revision 1 Service Information and Procedures Class A 2385072-16-8EN

Job Card DIAG A1000 - Gantry Diagnostic

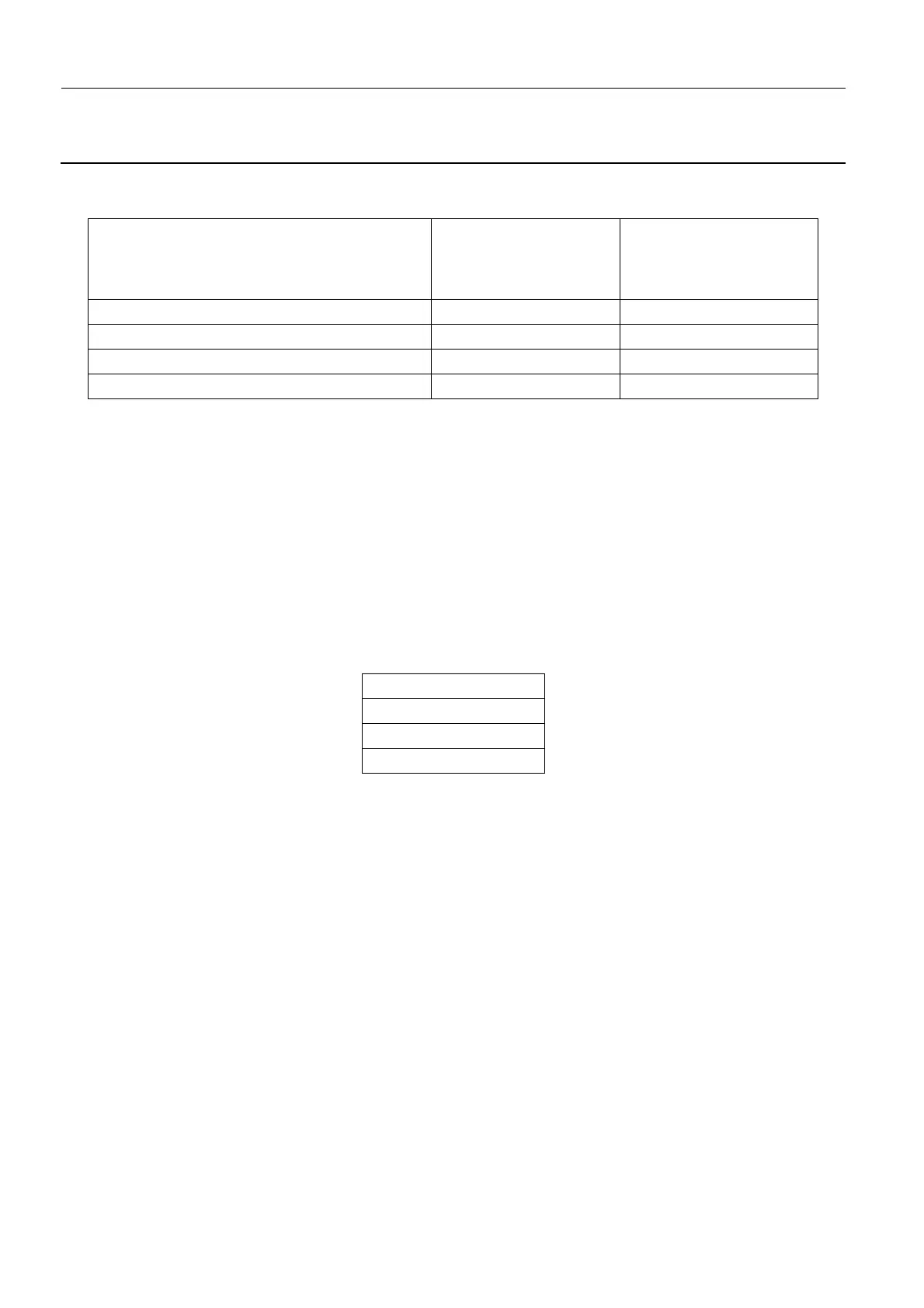

Check the potentiometer resistance between pins 1-2, 1-3, and 2-3. The acceptable resistances

between the pins are summarized in the table below.

If the measured resistance is not between the excepted limits, change the Compression Potentiome-

ter (see Job Card D/R A243 - Compression Potentiometer and Cable on page 1289).

Note:

The new Compression Potentiometer ordered will be a Type 3 Compression Potentiometer.

• If the error persists, check that the potentiometer screw runs normally as the trolley moves. If the

potentiometer screw does not move normally, change the Compression Potentiometer (see Job Card

D/R A243 - Compression Potentiometer and Cable on page 1289).

• If the error persists, change the compression motor and encoder (see Job Card D/R A244 - Com-

pression Motor with Encoder and Compression Belt on page 1297).

• If the error persists, change the Compression Board (see Job Card D/R A250 - Compression Board

on page 1323).

FRUs:

Recalibration is necessary if the Compression Board or the potentiometer is changed.

2-28 JC DIAG A1206 COMPRESSION CONTROL FAILURE

Diagnostic for:

122/006 error code (CAN code is 0x502B) step lost error

122/007 error code (CAN code is 0x6004) overspeed error.

• First make a careful visual check of the mechanical parts:

worm gear, upper (screw) brake, timing belt, motor unit.

• If no mechanical defect is detected:

- Check the brake air gap. The gap must be 0.2 mm for correct operation.

- Check the incremental encoder cable (W302) and its connection on the Compression Board (J4).

• Check the brake cable (W309) and brake coils by measuring the brake resistance. The resistance

value must be 192 ohm (+/-10 ohm). If it is out of these limits, change the brake and cables (see Job

Card D/R A246 - Manual Compression Brake on page 1301).

• If the error persists, remove power from the Compression Board. Apply 48 VDC on the brake cable

connector (check polarity!), then try to move the mechanics manually by pulling on the timing belt.

- If you cannot move by hand, first oil the mechanics.

Resistance on Type 1

or Type 2

Compression

Potentiometer

Resistance on Type 3

Compression

Potentiometer

Pins 1-3 (Resistance 1) 0.9 kOhm to 1.1 kOhm 9 kOhm to 11 kOhm

Pins 1-2 (Resistance 2) 0 kOhm to 1.1 kOhm 0 kOhm to 11 kOhm

Pins 2-3 (Resistance 3) 0 kOhm to 1.1 kOhm 0 kOhm to 11 kOhm

Resistance 2 + Resistance 3 must be between 0.9 kOhm to 1.1 kOhm 9 kOhm to 11 kOhm

Pot+cable

Mot+Enc with cable

Timing belt

Compression Board

Loading...

Loading...