PROGRAMMING EXAMPLES

22796-8000

June 1999

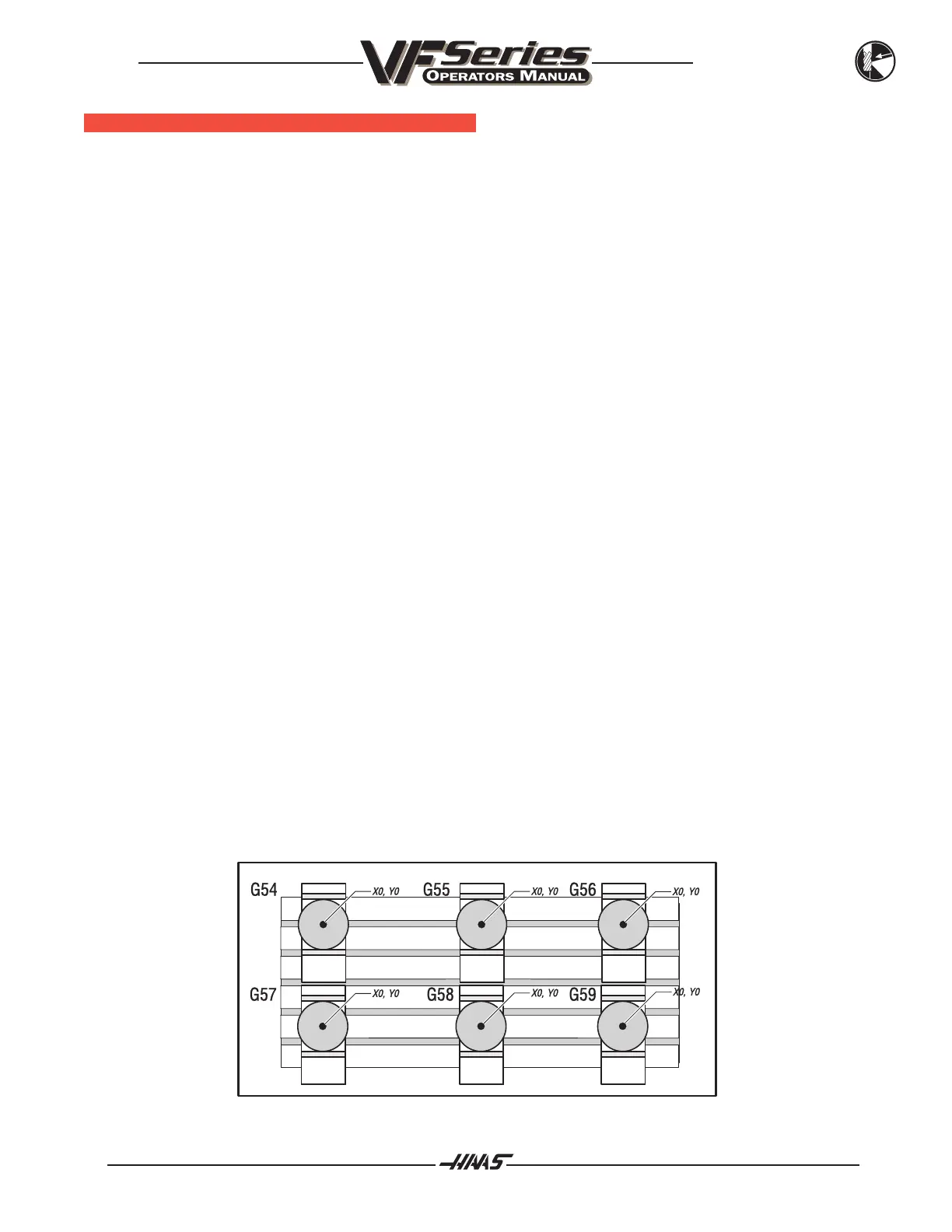

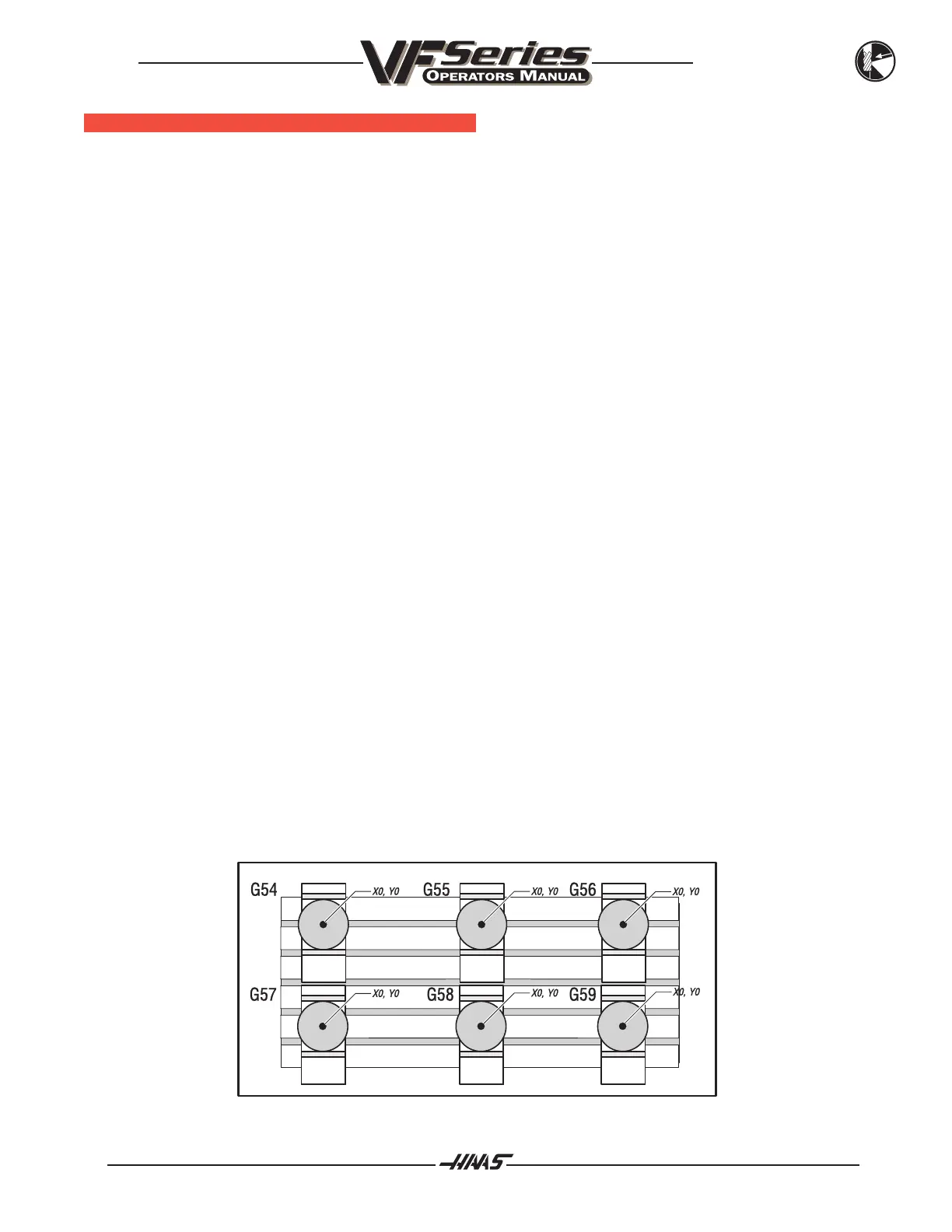

SUBPROGRAMS W ITH M ULTIPLE F IXTURES

So far we have learned that using subprograms with canned cycles can save programming time and help

reduce coordinate input error. Let's take this one step further. There are six vises mounted on the table. Each of

these vises will use a new X,Y zero. They will be called up in the program as G54 through G59. The machine

will have to be told where each of the vises is located on the table. By using an edge finder or an indicator, the

zero point on each part can be established. Use the part zero set key in the work coordinate offset page to

record each X,Y location. Once the X,Y zero position for each vise is in the offset page, the programming can

begin.

By looking at the next page, we can get a good idea of what this setup would look like on the machine table.

For an example, each of these six parts will need to be drilled at the center, X and Y zero.

%%

O2000 O3000

T1 M06 X0 Y0

G00 G90 G54 X0 Y0 S1500 M03 G83 Z-1.0 F15. R.1 Q.2

G43 H01 Z.1 M08 G00 G80 Z.2

M98 P3000 M99

G55 %

M98 P3000

G56

M98 P3000

G57

M98 P3000

G58

M98 P3000

G59

M98 P3000

G00 Z1.0 M09

G28 G91 Y0 Z0

M30

%

The following figure represents a multiple-fixture setup. Each vise will have an absolute zero once it is specified

in the program. This is done by using G54 through G59 and G110 through G129, a total of 26 possible posi-

tions.

Multiple fixture setup.

Loading...

Loading...