12

INSTALLATION

June 1999

96-8000

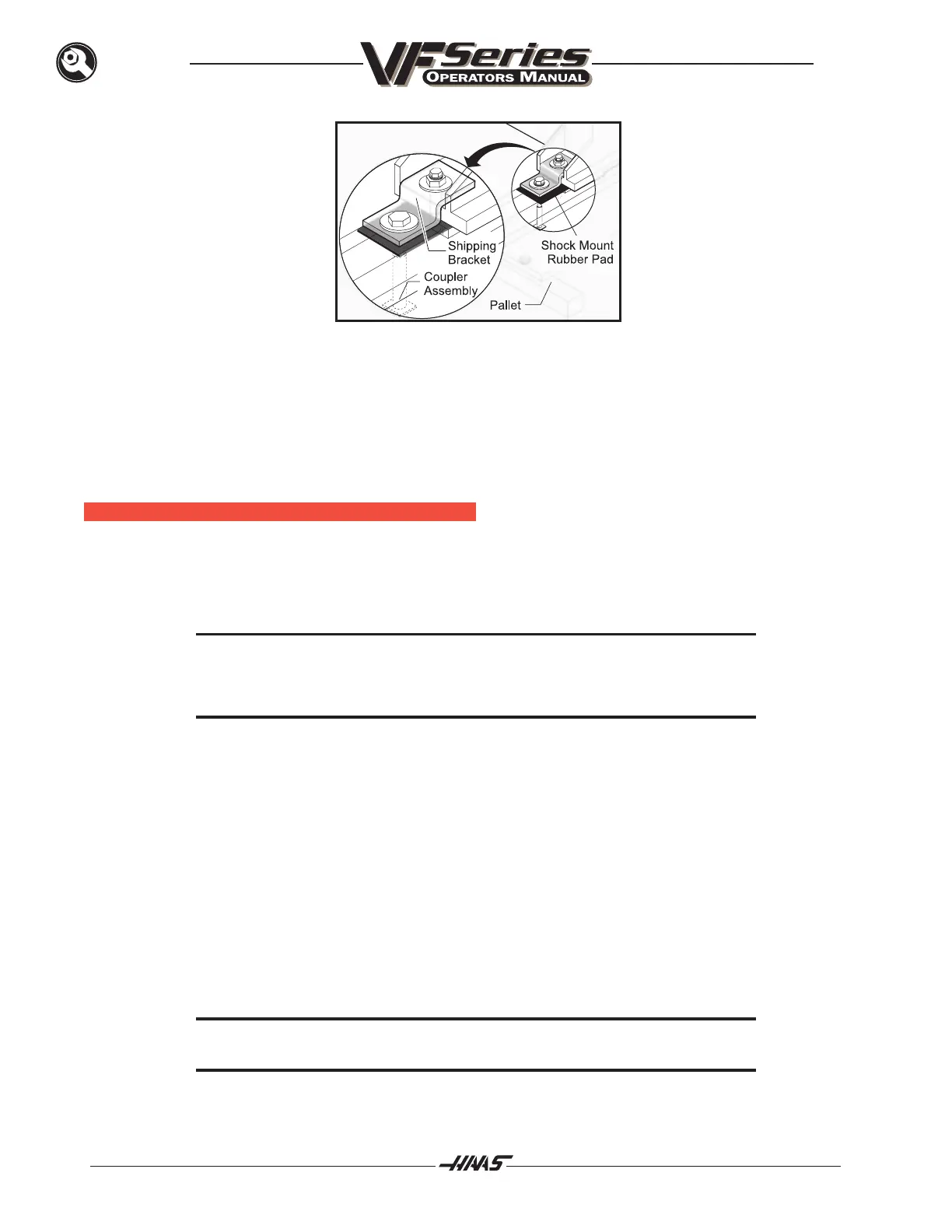

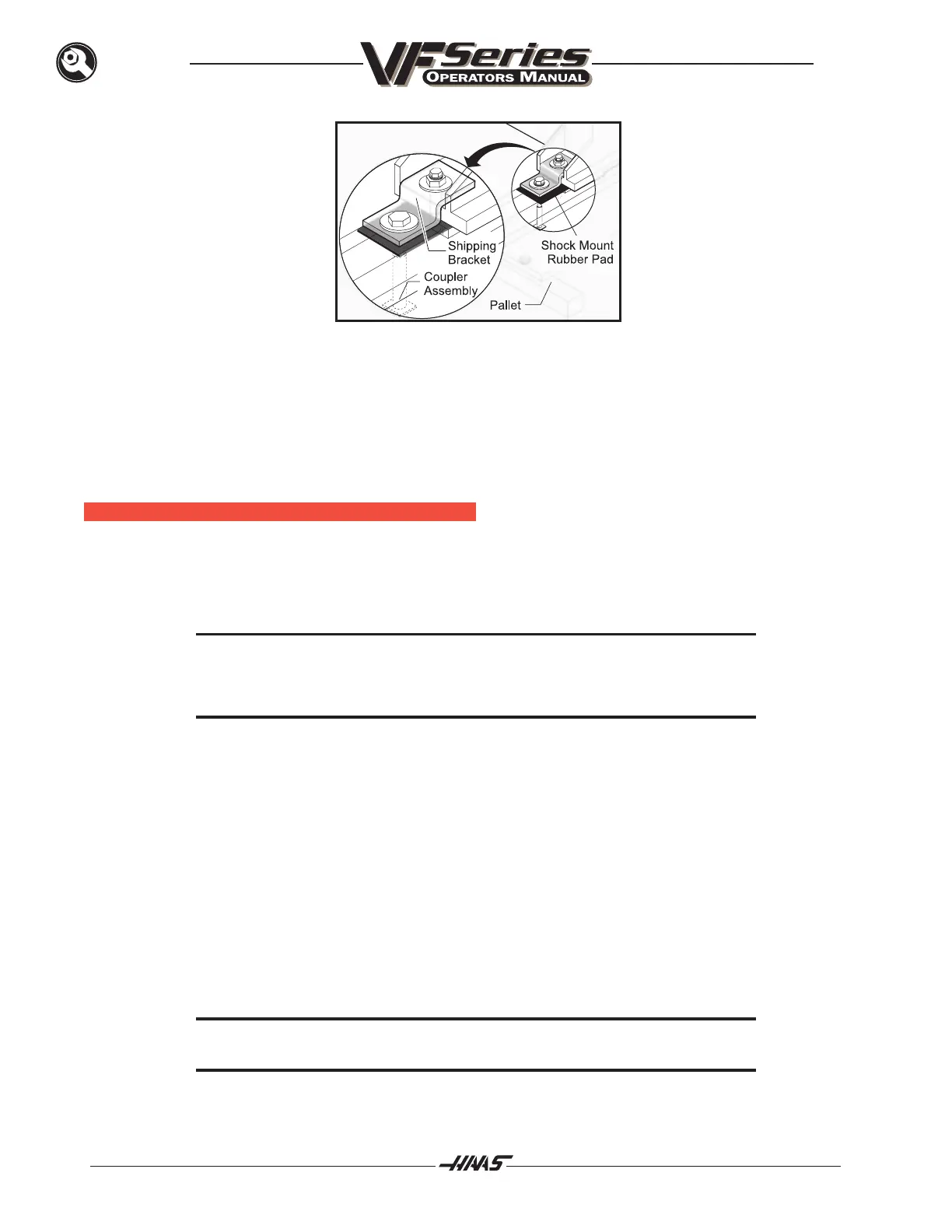

6. Unbolt shipping bracket.

7. Remove the nuts, on the leveling screws, holding the shipping bracket to the base casting. Re-

move the shipping brackets.

8. Lift the machine off the pallet.

SETTING IN P LACE

Keep in mind when moving the VMC that much of it's weight is concentrated in the column at the back.

Therefore, when lifting a VF-0/1/2 from the side, it is important that the forks of the forklift be positioned as

close to the back of the machine as possible without being on the pads.

CAUTION! Do not lift the machine any farther than necessary off the floor when moving

it, and move as slowly and cautiously as possible. Dropping the machine,

even from a height of a few inches, can cause injury, result in expensive

repairs, and void the warranty.

For the VF-0/1/2: The only acceptable way to move a VF-0/1/2 is to pick it up from the SIDE with a forklift.

Follow the machine weight and fork length specifications described earlier. The forks must be set as far apart

as possible without being on the pads. The forks must be positioned all the way to the back of the VMC and

they must extend at least 3" past the far side of the machine base. Also, there must be about approximately 6"

clearance between the forklift and the side of the machine.

For the VF-3 through 10: The VF-3 through 10 must be lifted from the BACK of the machine with a forklift.

IMPORTANT! Follow the machine weight and fork length specifications described earlier. The forks must be

set as far apart as possible without being on the pads. Also, there must be about approximately 6" clearance

between the forklift and the back of the machine.

Attempting to move the machine any other way may void the warranty.

CAUTION! When lifting the machine with a forklift, be careful not to damage the sheet

metal aprons with the forks.

Loading...

Loading...