MAINTENANCE

74 96-8000

June 1999

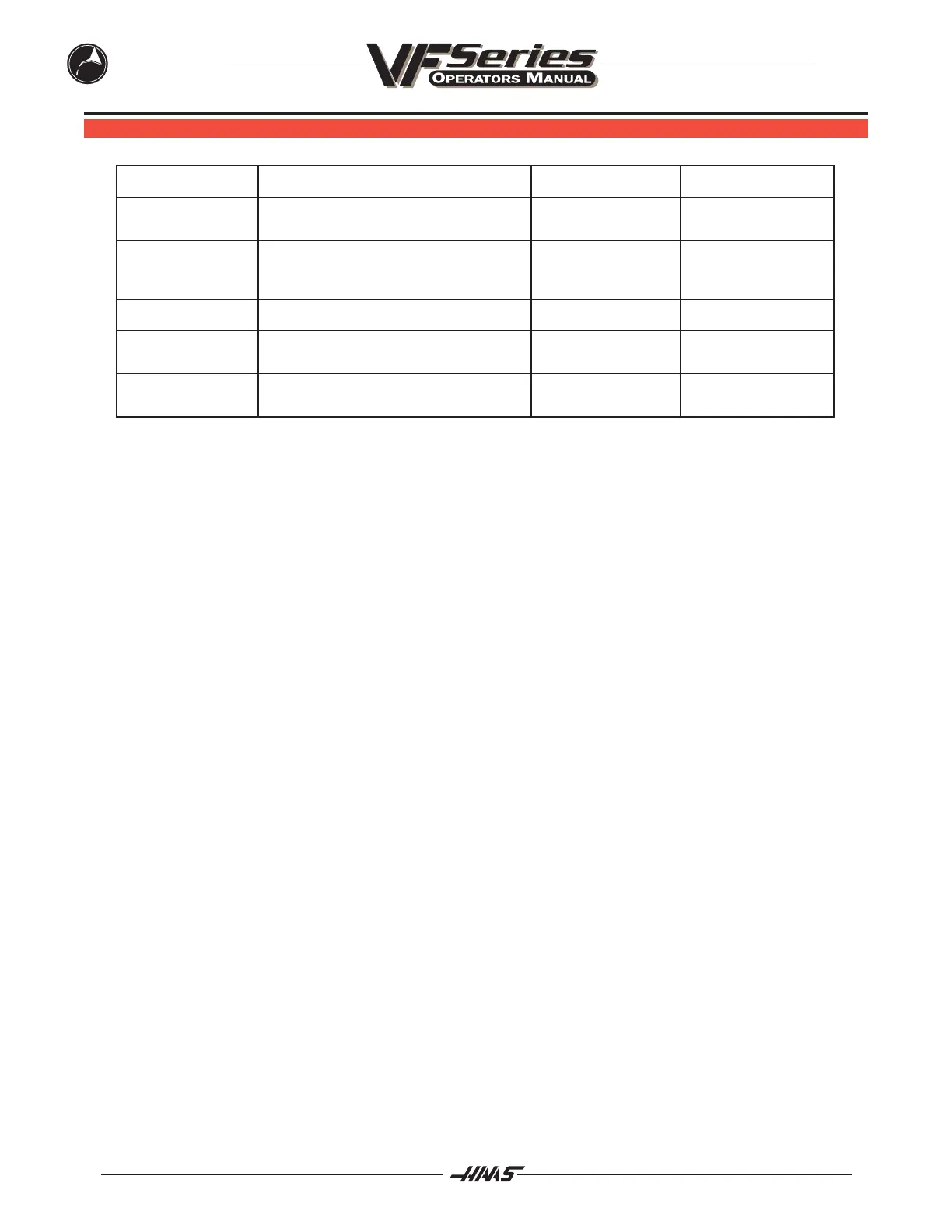

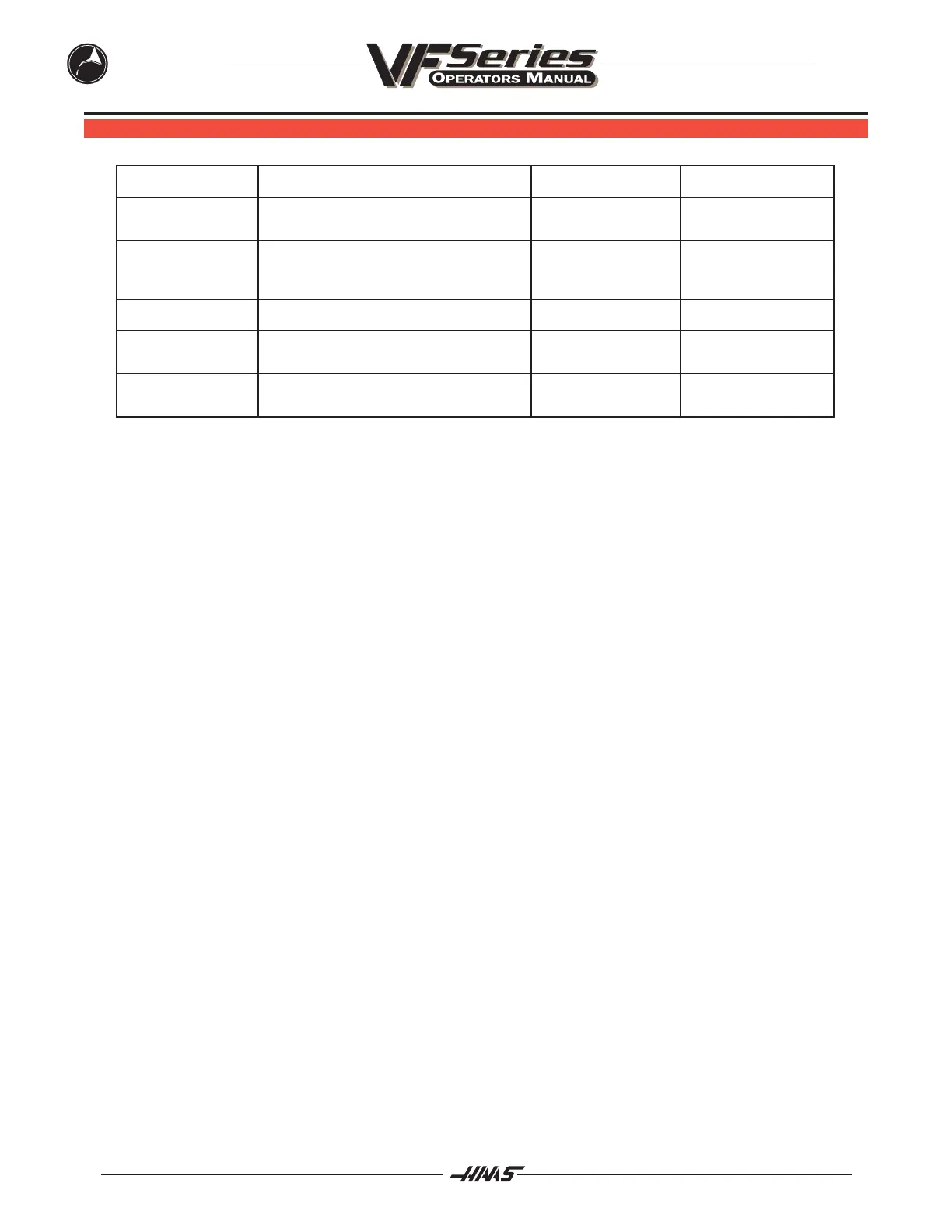

2.2 LUBRICATION C HART

METSYSSCITAMUENPDNAEBULYAWNOISSIMSNARTKNATTNALOOC

NOITACOL

ehtforaerehttalenaplortnocehtrednU

enihcam

eldnipsehtevobA

daeh

enihcamfoediS

NOITPIRCSED

.emitelcycetunim03htiwpmupnotsiP

gninrutsieldnipsnehwnoylnosipmuP

.gnivomsisixanehwro

SETACIRBUL

eldnipsdnastunllab,sediugraeniLylnonoissimsnarT

YTITNAUQ

elytspmupnognidneped.stQ5.2-2tQ-2repat04

zo63repat05

snollaG04

01-6FVsnollaG08

TNACIRBUL

2#artcaVliboM52ETDeliboM,elbulosretaW

citehtnys

WARNING!

The TSC pump is a precision gear pump and will wear out faster and lose pressure if abrasive particles are

present in the coolant.

When machining castings, sand from the casting process and the abrasive properties of cast aluminum

and cast iron will shorten pump life unless a special filter is used in addition to the 100 mesh suction filter.

Contact Haas Automation for recommendations.

Machining of ceramics and the like voids all warranty claims for wear and is done entirely at the customer's

risk. Increased maintenance schedules are absolutely required with abrasive swarf. The coolant must be

changed more often, and the tank thoroughly cleaned of sediment on the bottom. A larger coolant tank is

recommended.

Shortened pump life, reduction of pressure and increased maintenance are normal and to be expected in

abrasive environments and is not covered by warranty.

Loading...

Loading...