78 96-8000

June 1999

OPERATION

3.3 MACHINE H OME

The principal may be seen when doing a manual reference return of all machine axes. When a zero return

(ZERO RET) is performed at machine start up, all three axes are brought to the extreme positive direction until

the limit switch is reached. When this condition is satisfied, the only way to move any of the three axes is in

the negative direction. This is because a new zero was set for each of the three axes automatically when the

machine was brought Home. This is placed at the edge of each axes travel. In effect, now the positive quad-

rants cannot be reached, and all the X and Y moves will be found to be in the X-, Y- quadrant. It is only by

setting a new part zero somewhere within the travel of each axis that other quadrants are able to be reached.

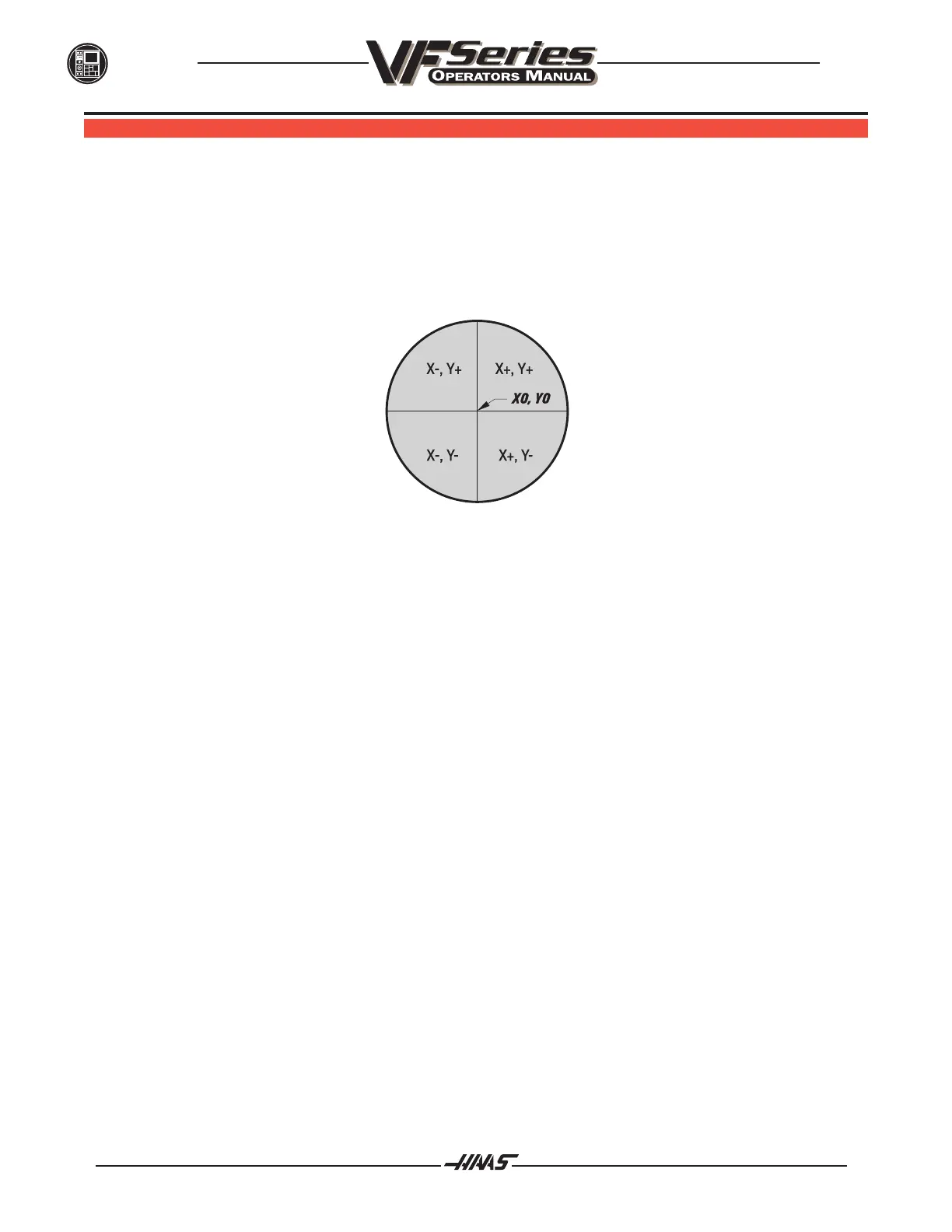

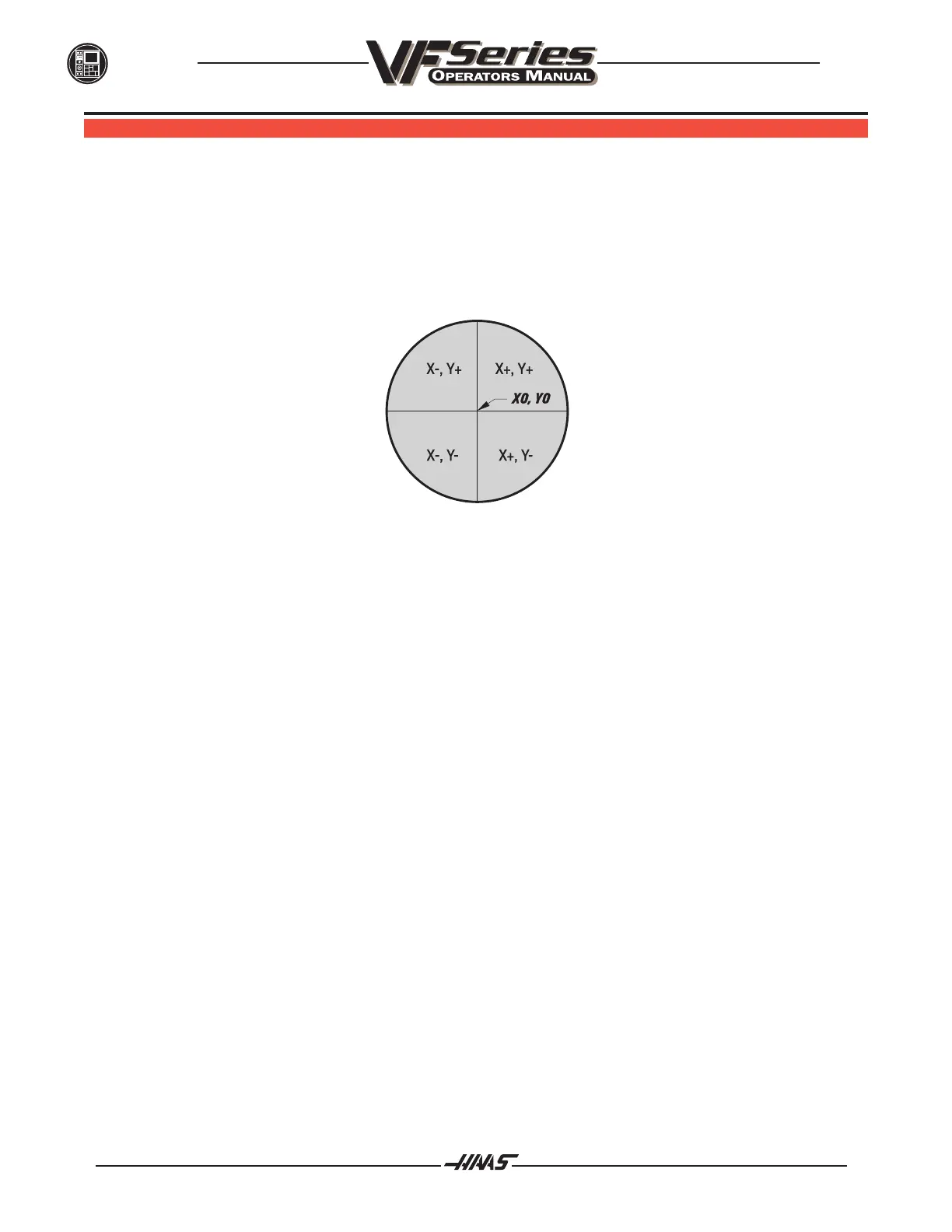

Fig. 3-5 All four quadrants will have to be accessed to machine this part.

Sometimes it is useful in the machining of a part to utilize more than one of the X,Y quadrants. A good example

of this is a round part that has its datum lines running through the center. The setup of such a part may look

like Fig. 3-5.

These are just some examples of how to make use of the four quadrants of the X and Y axes on the machine.

As more experience is gained in the machine tool programming and setup techniques, each programmer and

setup person develops their own methods and style. Some methods will be faster than others, but each

individual will have to determine the needs of each job in question, and reflect back on notes and the previous

jobs completed.

Loading...

Loading...