56

INSTALLATION

June 1999

96-8000

SECURE T HE F RONT

CAUTION! No heavy or abrasive ties, chains, wraps, or bindings should be placed in contact with painted or

plastic parts of the machine. Damage caused by ignoring this caution is NOT covered by the warranty.

1. Make sure that the machine is locked up and remove any loose material from the table area.

2. Place a pad between the doors, pull them closed, and secure them with two wire ties through the

handles.

3. Wrap some padded packing material around the pendant (control box) and secure with some

heavy-duty tape. Also, place a couple inches thickness of foam or other packing material on the

enclosure behind the control panel.

4. For the VF-3/4, remove the support bolt from the control arm, and swing the arm back and into

shipping position. Put the shipping brace into place and secure with two bolts.

MOVE O NTO T HE P ALLET

NOTE: If you did not store your shipping materials, pallets and crates are available

from Haas Automation. Contact the factory for information.

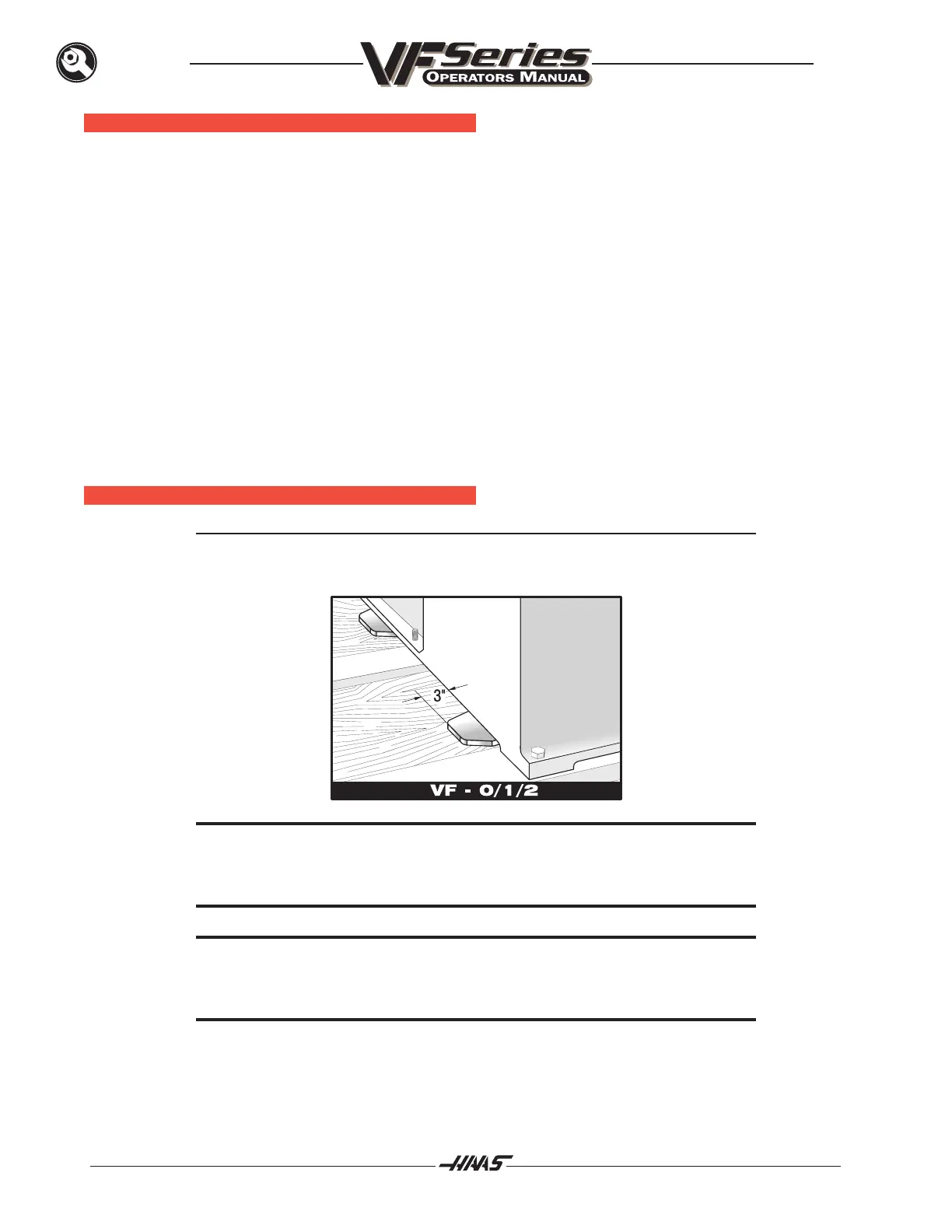

IMPORTANT! Keep in mind when moving the VMC that much of it's weight is concentrated

in the column at the back. Therefore, when lifting a VF-0/1/2 from the

side, it is important that the forks of the forklift be positioned as close to

the back of the machine as possible without being on the pads.

CAUTION! Do not lift the machine any farther than necessary off the floor when moving

it, and move as slowly and cautiously as possible. Dropping the machine,

even from a height of a few inches, can cause injury, result in expensive

repairs, and void the warranty.

Loading...

Loading...