61

INSTALLATION

June 1999

96-8000

PROCEDURE

1. Prepare the machine as described in the "Preparation for Shipping the VMC" section up to the

point of putting it on a pallet. Make sure the spindle is on tool number one. Replace and secure

the shipping bracket -- even for the shortest moves. Tie-wrap the doors together and stow the air

filter from the control panel door (on the back of the machine) inside the panel.

2. To transport the machine without a pallet, you need four metal tie-downs. (Additional tie-downs can

be purchased from Haas if you have lost yours.) After raising the machine with a forklift, turn the

four corner levelling adjustment screws clockwise, with the 9/16" hex wrench, until they a protrude

at least ½" through the bottom of the machine. Tighten the ¾-11 nuts until the levelling screws are

secured in the casting. Place a metal tie-down on each of the four levelling screws (the small hole

in the tie-down slips over the top of the screw and rests on the top of the ¾-11 nut). Position the

tie-downs so they are at 45

0

angles to the front, back, and sides of the machine and secure them

on the screws with additional ¾-11 nuts.

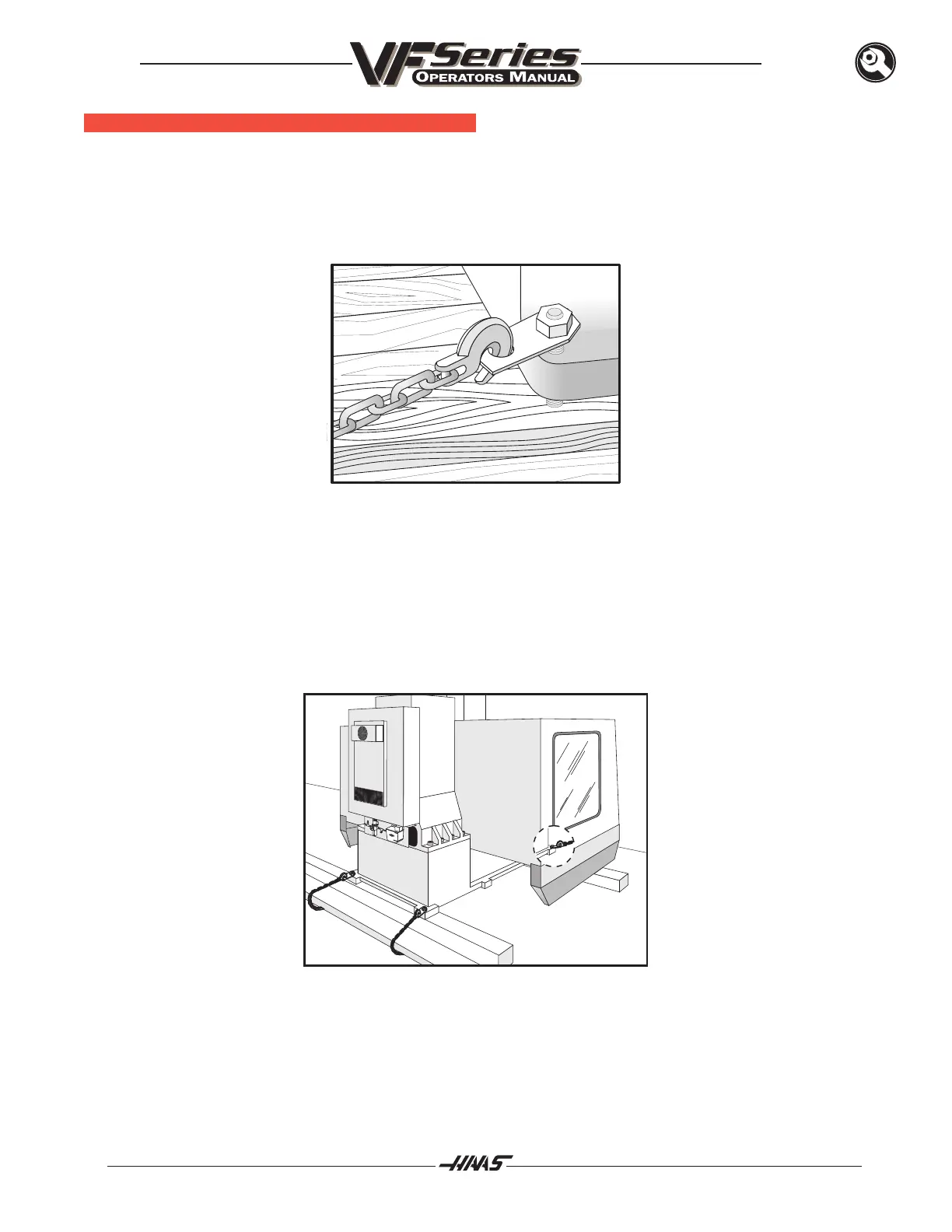

3. Place two 4 x 4's that are least 5' long on the truck. Lower the VMC onto the truck and align the

two pieces of lumber under the leveling screws at the corners of the machine. Remove the forklift

and have the rigger secure the machine using the large holes in the four tie-downs as the attach-

ment points for the riggers' chains. When the chains are tightened, the leveling screws dig into the

4 x 4's to help hold the machine in place.

Loading...

Loading...