96-8000 427

OPTIONS

June 1999

PROGRAMMING

PROGRAM C OMMANDS

The APC is controlled by a program in CNC memory. M codes are used in the parts program to control the

APC. The pallet change routine is run by using an M50 code in the parts program, which accesses a macro

program that cannot be viewed or edited. In order for M50 to work, Parameter 81 (M MACRO CALL 09000)

must be set to 50.

The APC can be programmed to run one program on both pallets, or a different program on each pallet. The

"Sample Programs" section consists of two basic programs: the first sample program runs the same part on

both pallets, and the second program runs a different part on each pallet.

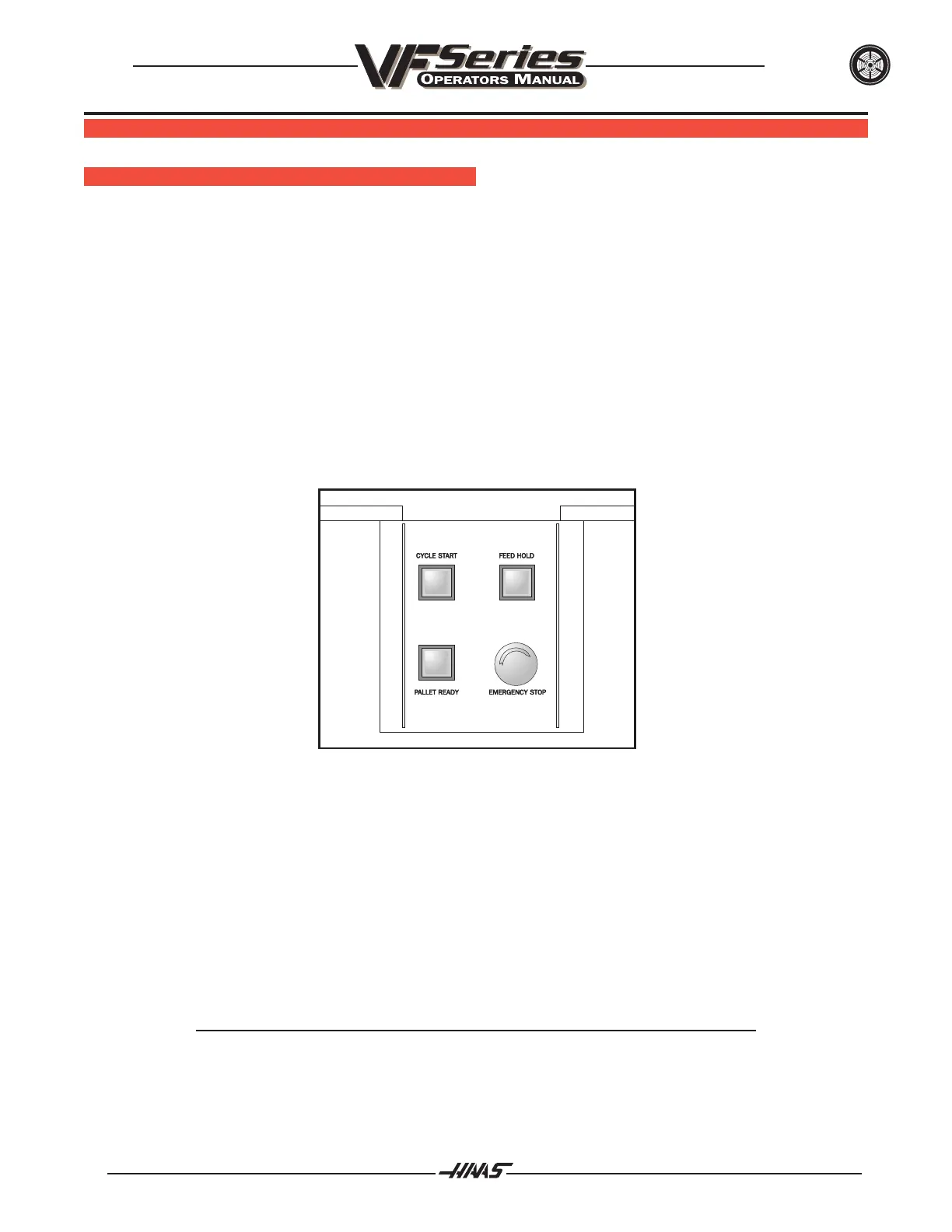

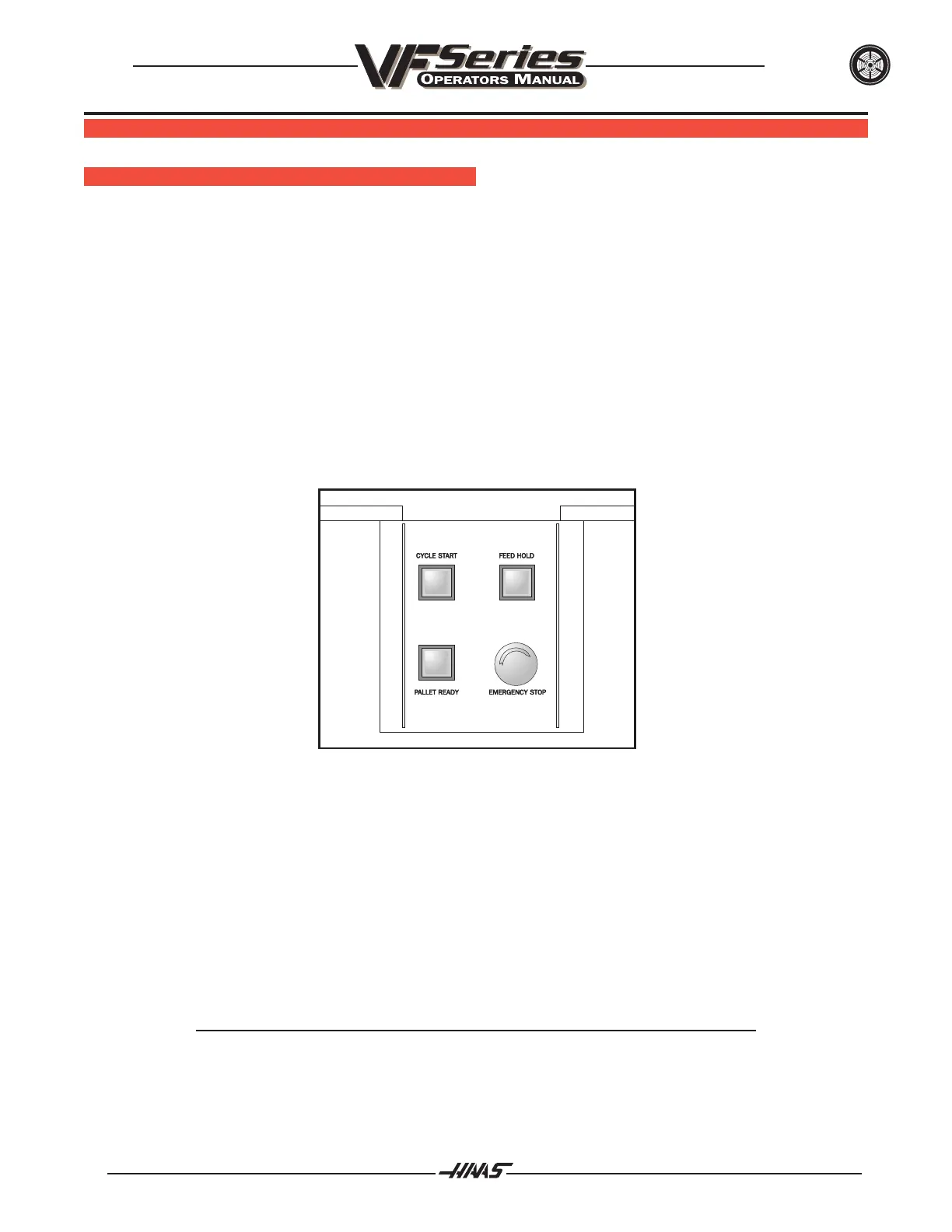

The APC has its own operator's panel, which includes CYCLE START, FEED HOLD, and EMERGENCY STOP

buttons that perform the same functions as those on the VMC control panel. This panel also includes a

PALLET READY button, which is used for APC functions (Refer to figure 11.29).

Figure 11.29 APC operator's control panel (top view).

When an M36 is programmed prior to an M50, the APC will flash the "PALLET READY" light at the completion

of the user's part program, and wait until the PALLET READY button has been pressed before performing the

pallet change. This M code is optional, but is recommended because it prevents a pallet change from occurring

before the operator is ready. The PALLET READY button can be pressed at any time and will be recognized

when the next program is finished and a pallet change is required.

Important! If any alignment adjustments are necessary during operation, refer to the "Installation" section and

modify the appropriate macro variables.

Note: Use caution when changing macro variable #510 during operation. An alarm

will be received if the control and the limit switches disagree on pallet position.

Loading...

Loading...