84 96-8000

June 1999

OPERATION

QUESTION:

Can we combine the second and third lines, excluding the M08 code? If so, why do we write the lines sepa-

rate?

ANSWER:

Yes. The four G codes G00, G90, G54, and G43 all belong to different groups. Remember, no two G codes of

the same group can be listed on the same line. However the main reason for using two lines is SAFETY.

Remember, only one line of information can be executed at a time. The X and Y coordinates will position first,

then the tool length and the Z coordinate will execute. If combined, all three axes will move simultaneously, and

any interfering clamps or fixtures can be struck and/or destroyed. When combining X, Y, and Z in positioning,

chances of crashing the machine are greater.

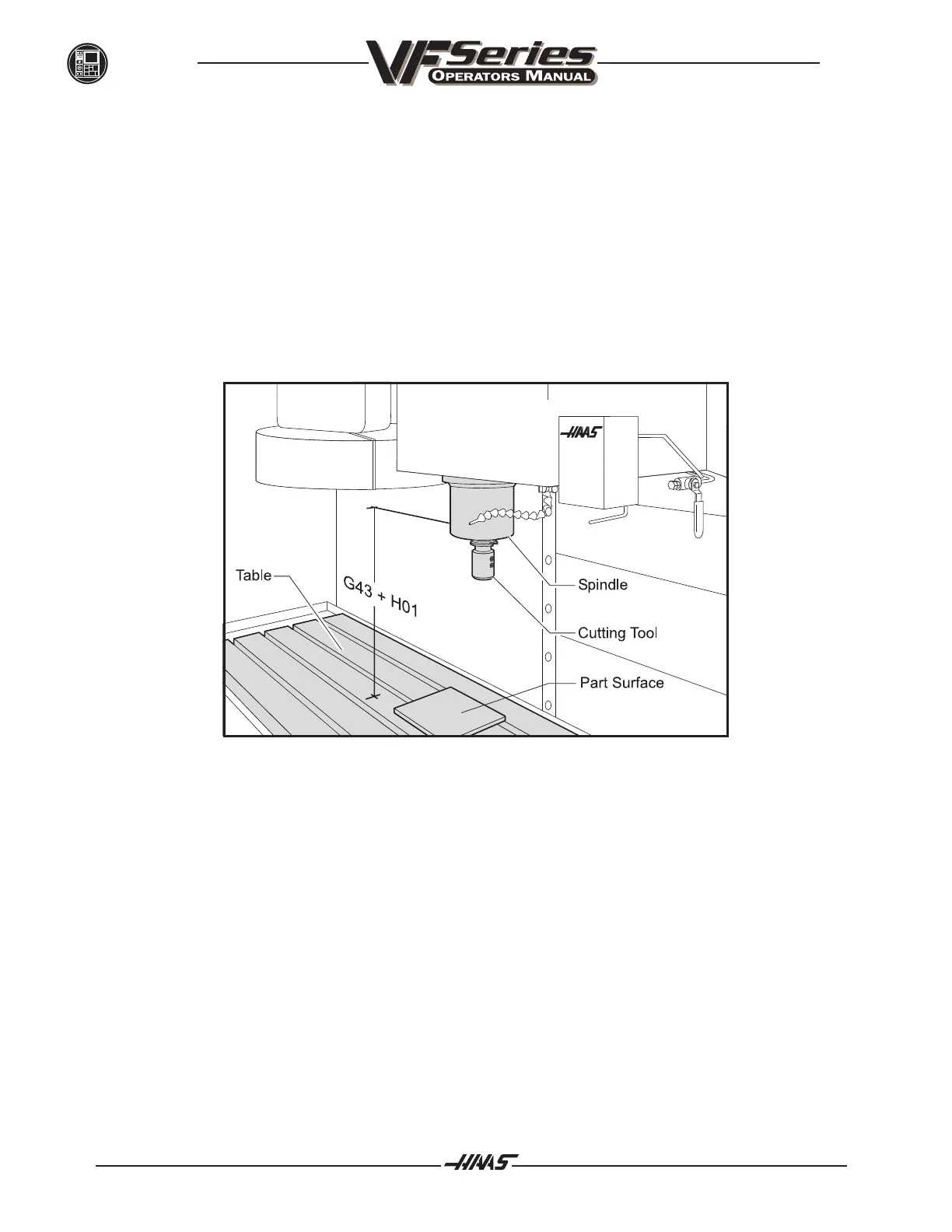

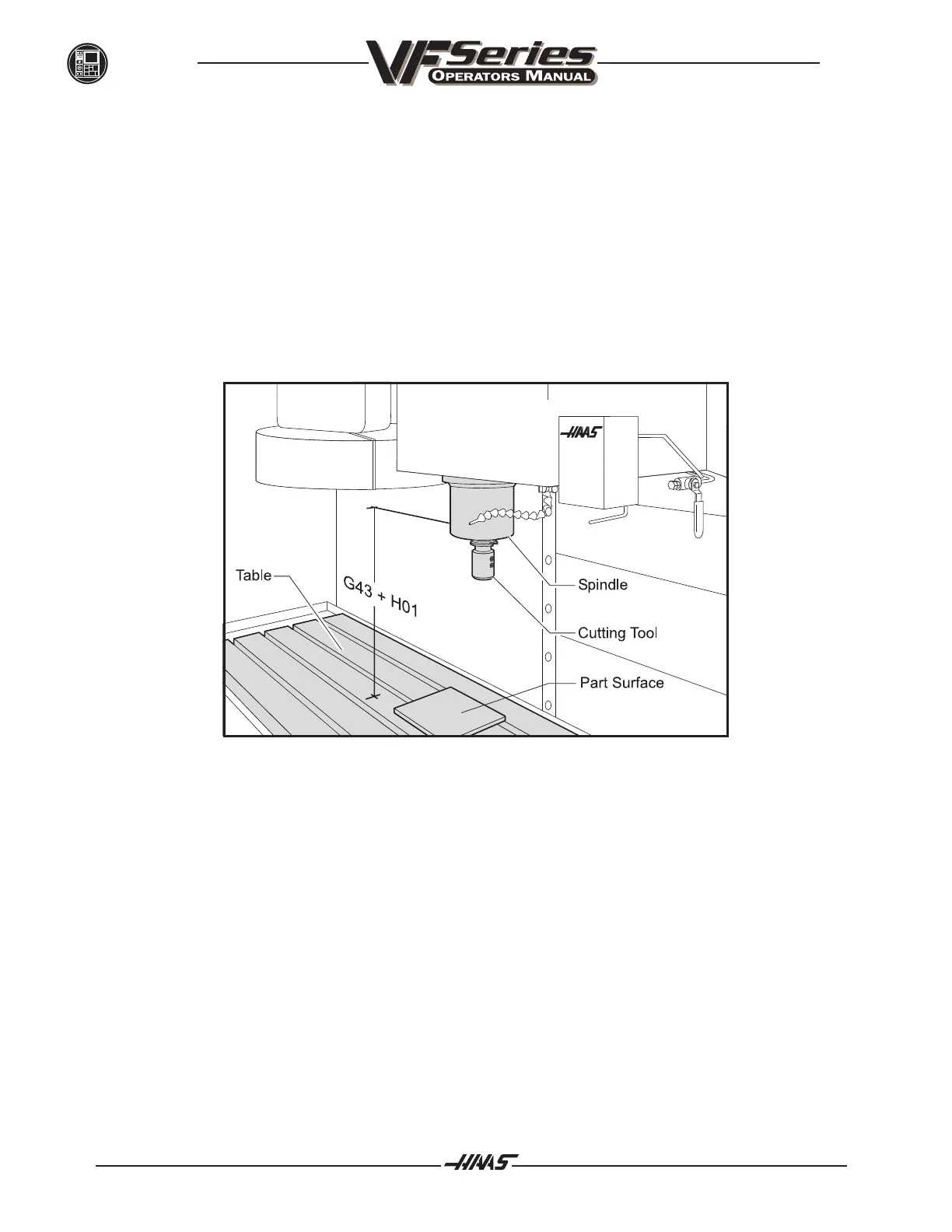

Fig. 3-7 Tool length offset and tool length compensation.

Tool number should always remain numerically matched with the tool length offset number. Setting 15 (the H &

T agreement) will ensure the tool number and tool length offset will match. (Ex. T1 in line #1 should have H01

in line #3, and T2 should have H02 in line #3.)

Loading...

Loading...