Appendix 13 Making Your Own Measurement Leads, Making Connections to the Multiplexer

A29

Appendix

Recommended Measurement Lead Specifications

Example: UL1354, UL1631, UL1691

Before Wiring

See: "Appendix 7 Unstable Measured Values" (p. A12)

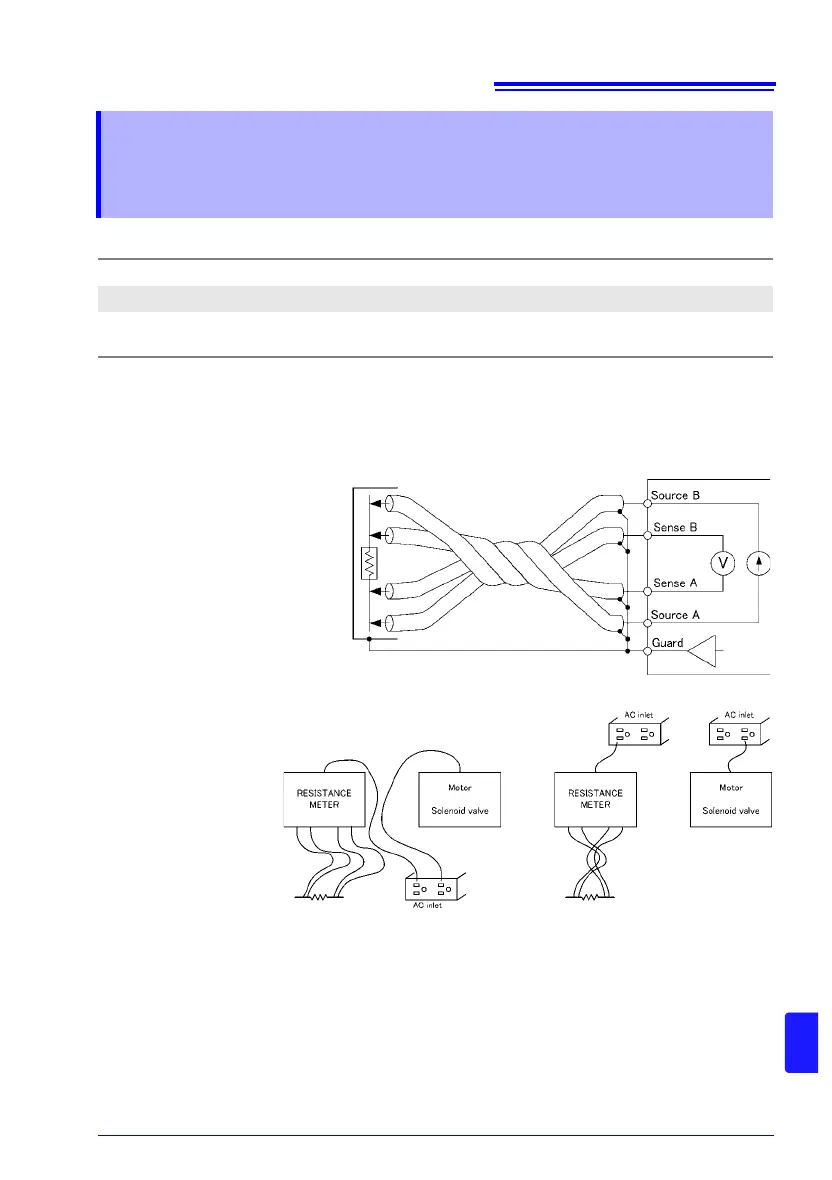

• Use shielded wiring for

measurement leads and

connect the shield potential

to the instrument’s GUARD

terminal. Use the GUARD

potential to shield probes

and near the measurement

target.

Twist the four wires together

and keep loop area small.

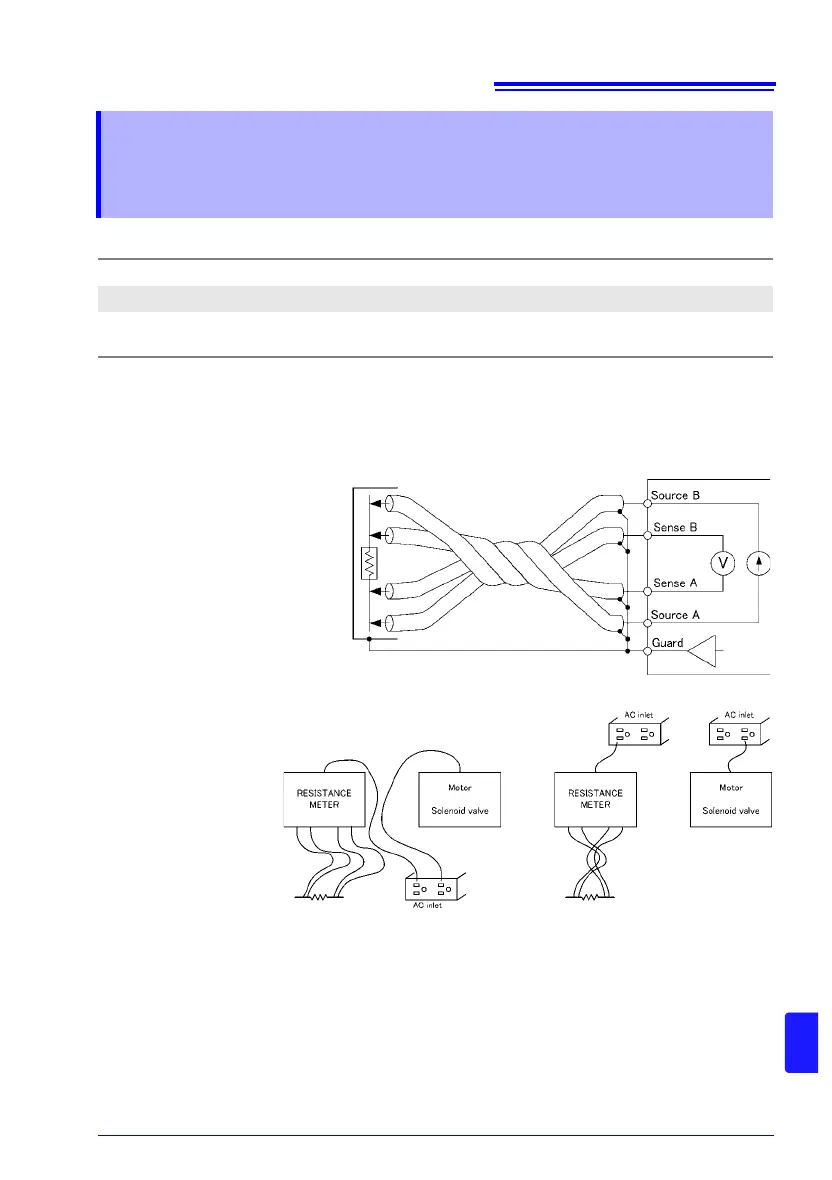

• Keep measurement

leads and the mea-

surement target

away from high-cur-

rent, high-voltage,

and high-frequency

wires (withstanding

voltage testers,

power cords, motors,

solenoid valves).

The phenomenon of induction becomes pronounced in the 10 m and 100 m ranges

(when the measurement current is set to 1 A). Variations in lead position or shape may

cause measured values to vary. Exercise care to prevent positions and shapes from

changing. Additionally, measurement leads and measurement targets should be kept as

far as possible from metallic objects.

• When using two or more RM3545 units, do not group the wires from multiple instruments

together. Induction phenomena may cause measured values to become unstable or the

contact check circuit to generate erroneous results.

Appendix 13 Making Your Own Measurement

Leads, Making Connections to the

Multiplexer

Conductor resistance

500 m/m or less

Capacitance

150 pF/m or less

Cable dielectric material

Polyethylene (PE), Teflon* (TFE), polyethylene foam (PEF)

Insulation resistance at least 100 G (RMS)

Wiring Diagram

Static shielding

Poor example Good example

Power supply on a separate circuit

The same inlet

is used.

Measurement leads are

close to power supply wires.

Loading...

Loading...