4-37

4.12 Troubleshooting when Fault Occurs in Viscometer

Follow the troubleshooting steps below when the error occurs in viscometer.

[Caution] If “Viscosity Reading Instability” or “Viscosity Readings Out of Range” is

occurred , the IJP will automatically switch to the dot count system and operate.

(1) Viscosity Reading Instability

・ Phenomenon: Some unevenness occurred in 5-times measurement results of fall

time. (The difference between the maximum and minimum values

of fall time exceeded 10% of average value.)

・ Estimated cause: Entrance of foreign object

Troubleshooting:(a) Retry “calibration”. If the fault is not recovered, proceed to (b).

(b) Disassemble and clean viscometer. Proceed to (c) if no

recovery is made.

(c) Replace viscometer.

(2) Viscosity Readings Out of Range

・ Estimated cause: Ink adhered to the IN-side of viscometer.

Troubleshooting: Disassemble and wash viscometer.

・ Estimated cause: Proximity sensor was faulty.

Troubleshooting: Replace the proximity sensor.

If there is no recovery with the above troubleshooting, replace the viscometer.

(3) Inside Temperature Too High

・ Cause: Thermistor was faulty.

Troubleshooting: Confirm the connection of connector and/or replace the thermistor.

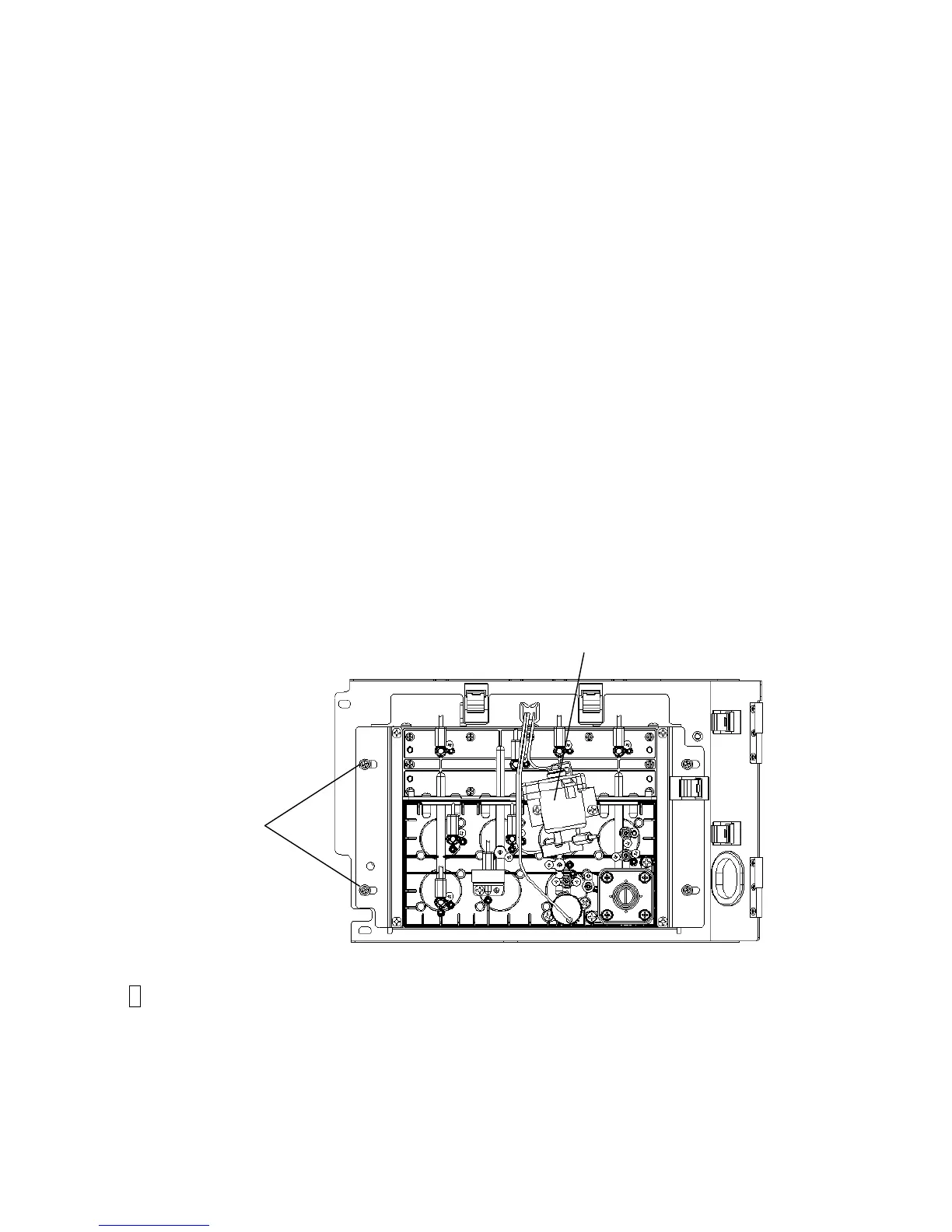

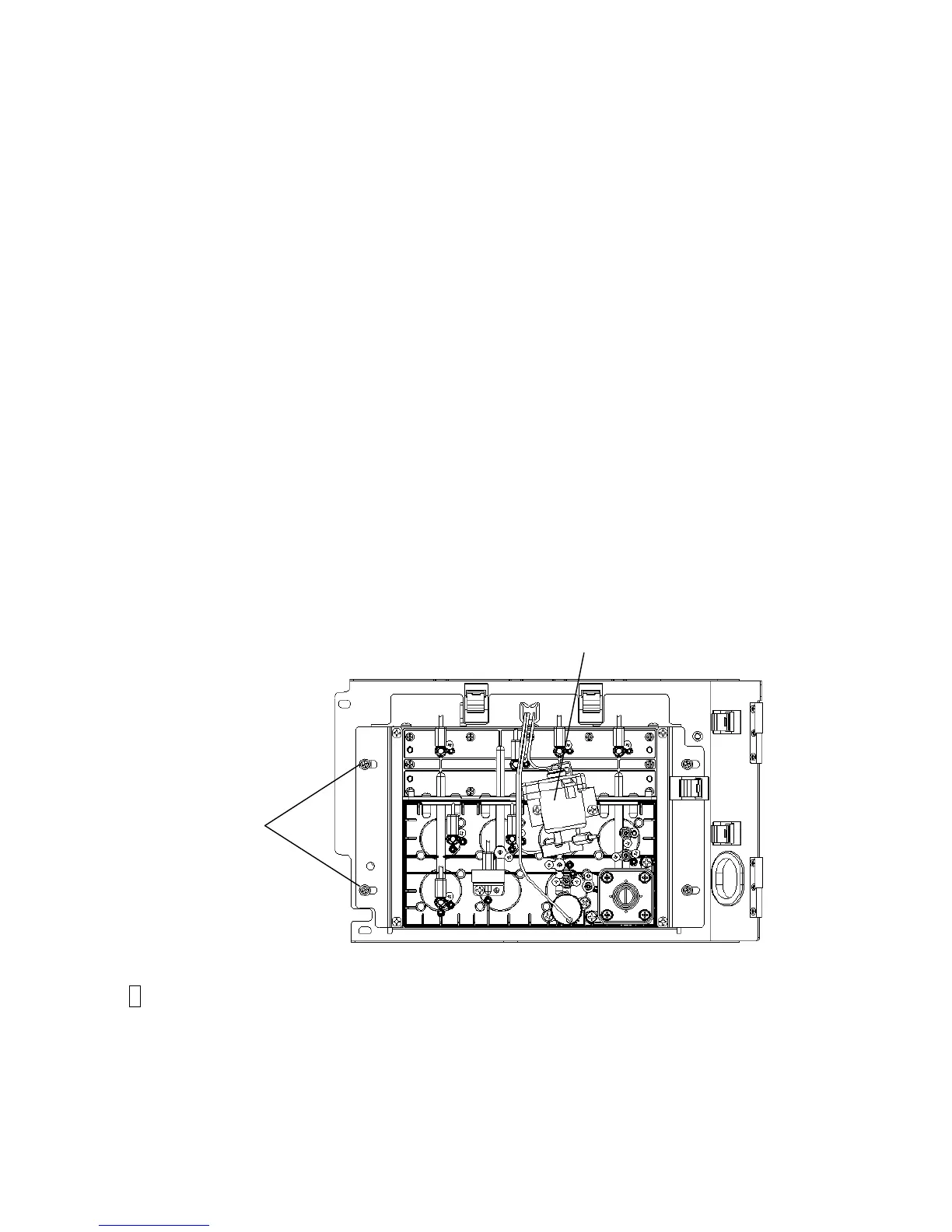

4.12.1 Viscometer removal procedure

[Caution] Disposing of ink is not necessary.

1 Removing the viscometer IN-side tube

(A) Follow the procedures described in “4.1.2 Access to the parts on the front side of

the equipment” and make the viscometer visible.

(B) Release the viscometer IN-side tube (mark G) from the clamp.

(C) Turn the lock nut to remove it.

Fixing screws

Viscometer

Loading...

Loading...