1.3.2 Installation procedure

Perform an installation work of the unit according to the following procedure at the

unpacking.

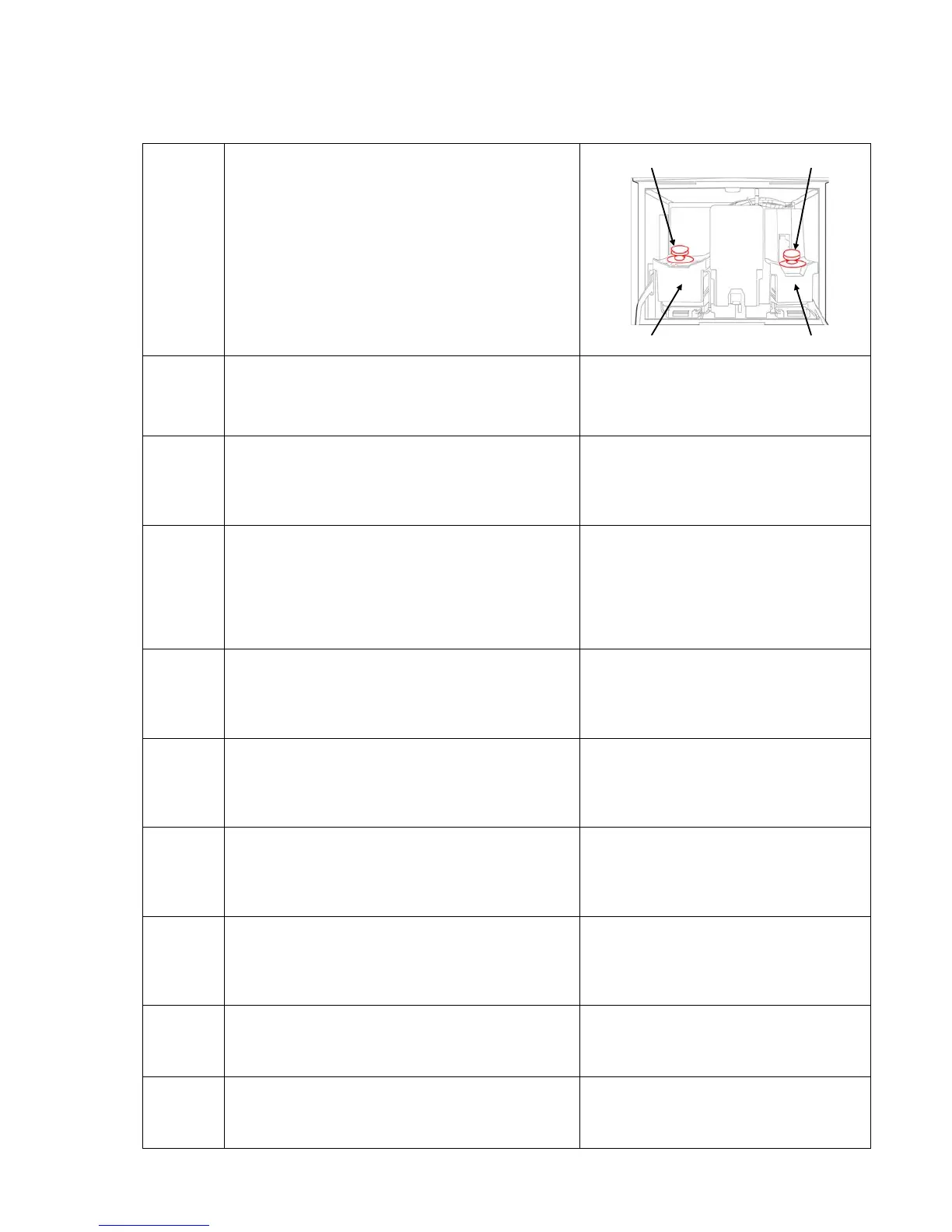

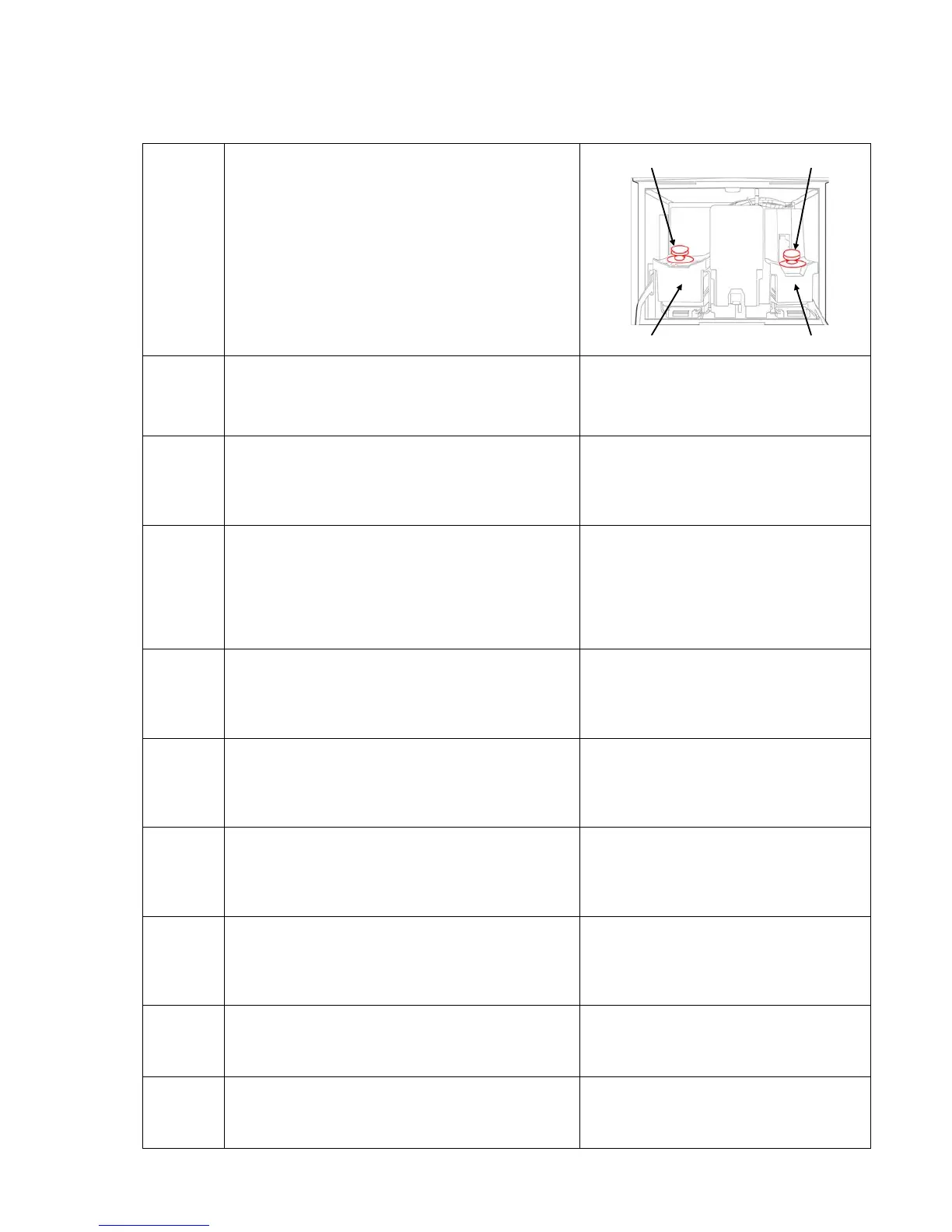

The cap of the compensating port is detach.

Service personnel maintenance mode setup

2.1 Setting of service personnel

maintenance mode

Selection of ink type(Touch screen

2.2 System environment setup

Fill ink and makeup in each reservoir.

8. Ink and Makeup replenishment

<NOTE>If the makeup in the Cartridge

bottle is used as a cleaning solution,

pour the contents in the cleaning bottle

before the cartridge bottle is set.

(For filling makeup path and adjusting ink stream

position)

Replenish the ink in the main ink tank.

And fill ink in the ink circulation routes.

(Replace solvent with ink)

Press Installation Ink refill on

< Circulation control >.screen.

<NOTE>Insert the tip of the Printhead

into the beaker at Ink refill.

Ink replenishment (second replenishment)

(Fill ink into a circulating system)

Press Ink drainage on < Circulation

. Follow the guidance

displayed on the screen to perform Ink

Ink replenishment (second replenishment)

(Fill ink into a circulating system)

Press Ink refill on < Circulation control

<NOTE>Insert the tip of the Printhead

into the beaker at Ink refill.

(Set pressure to the standard value of every ink)

6.9 Adjusting the pressure

Adjustment of excitation voltage

(Touch screen operation, automatic acquisition)

2.3.1 Excitation adjustment

Supply port cap

Ink reservoir Makeup reservoir

Supply port cap

Loading...

Loading...