ENGINEERING MANUAL OF AUTOMATIC CONTROL

VALVE SELECTION AND SIZING

449

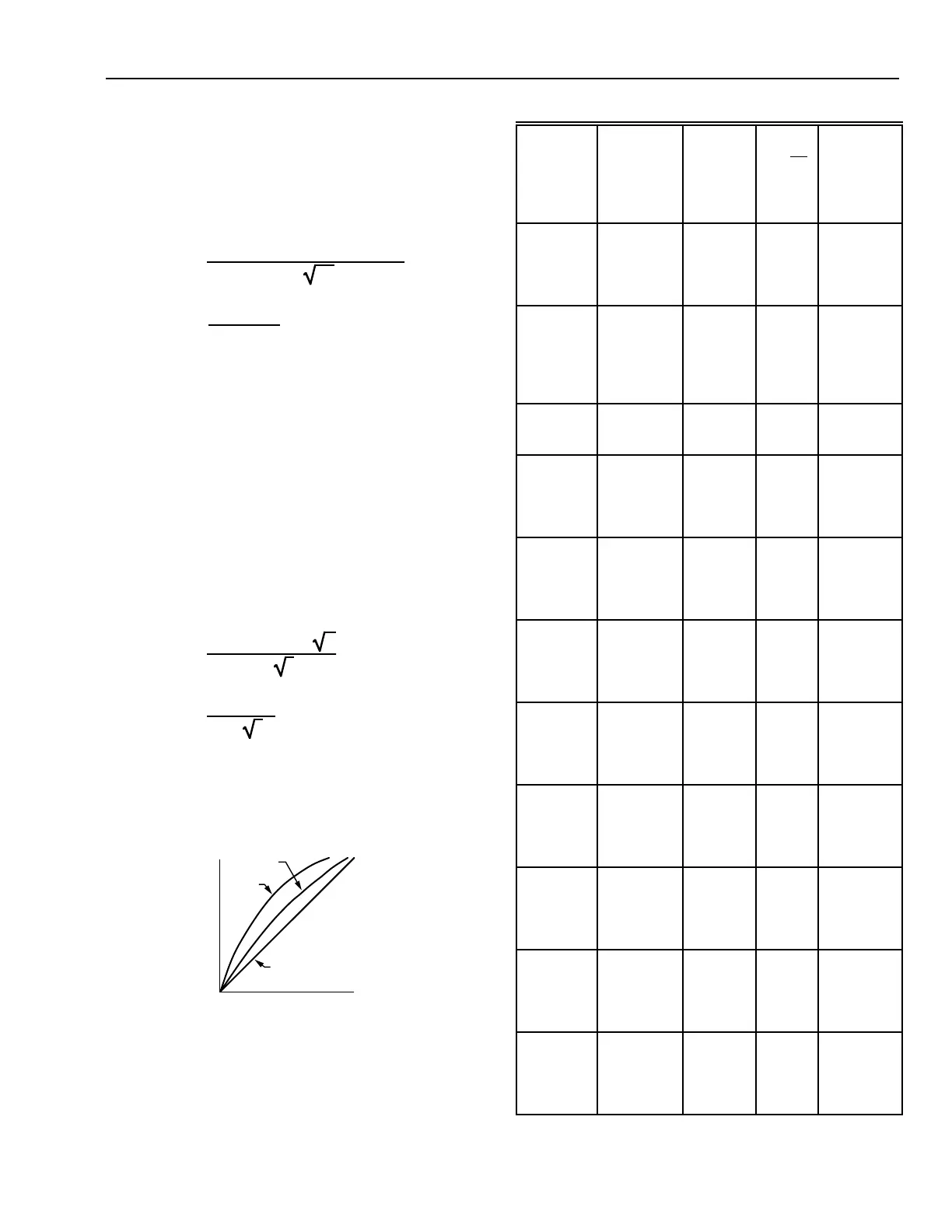

Vacuum,

Inches of

Mercury

Boiling

Point or

Steam

Temp-

erature

Deg F

Specific

Volume

(V),

cu. ft/lb

公

V

(For

valve

sizing)

Maximum

Allowable

Pressure

Drop, psi.

29

25

20

15

14

76.6

133.2

161.2

178.9

181.8

706.00

145.00

75.20

51.30

48.30

26.57

12.04

8.672

7.162

6.950

0.23

1.2

2.4

3.7

3.9

12

10

8

6

4

2

187.2

192.2

196.7

201.0

204.8

208.5

43.27

39.16

35.81

32.99

30.62

28.58

6.576

6.257

5.984

5.744

5.533

5.345

4.4

4.9

5.4

5.9

6.4

6.9

Gage

Pressure,

psig

0

1

2

3

4

212.0

215.3

218.5

221.5

224.4

26.79

25.20

23.78

22.57

21.40

5.175

5.020

4.876

4.751

4.626

7.4

7.8

8.4

8.8

9.4

5

6

7

8

9

227.1

229.8

232.3

234.8

237.1

20.41

19.45

18.64

17.85

17.16

4.518

4.410

4.317

4.225

4.142

9.8

10.4

10.8

11.4

11.8

10

11

12

15

20

239.4

241.6

243.7

249.8

258.8

16.49

15.90

15.35

13.87

12.00

4.061

3.987

3.918

3.724

3.464

12.4

12.8

13.4

14.8

17.4

25

30

35

40

45

266.8

274.0

280.6

286.7

292.4

10.57

9.463

8.56

7.826

7.209

3.251

3.076

2.93

2.797

2.685

19.8

22.4

24.8

27.4

29.8

50

55

60

65

70

297.7

302.6

307.3

311.8

316.0

6.682

6.232

5.836

5.491

5.182

2.585

2.496

2.416

2.343

2.276

32.4

34.8

37.4

39.8

42.4

75

80

85

90

95

320.0

323.9

327.6

331.2

334.6

4.912

4.662

4.445

4.239

4.060

2.216

2.159

2.108

2.059

2.015

44.8

47.4

49.8

52.4

54.8

100

110

120

130

140

337.9

344.1

350.0

355.2

360.9

3.888

3.595

3.337

3.12

2.923

1.972

1.896

1.827

1.766

1.710

57.4

62.3

67.4

72.3

77.4

150

160

170

180

190

366.2

370.6

375.5

379.6

383.9

2.746

2.602

2.462

2.345

2.234

1.657

1.613

1.569

1.531

1.495

82.3

87.4

92.3

97.4

102.3

63.5 = A scaling constant.

s=0

Substituting the quantity of steam, specific volume of

steam, and pressure drop in the C

v

formula shows that

Valve V1 should have a C

v

of 24.17 or the next higher

available value (e.g., 25).

C

v

=

(1 + 0.00075 x 0) x 750 x

63.5 5.6

=

3637.5

63.5 x 2.37

= 24.17

NOTE: If P

avg

is rounded off to the nearest value in Table

5 (2 psi), the calculated C

v

is 24.30.

Select a linear valve providing close control with a capacity

index of 25 and meeting the required pressure and

temperature ratings.

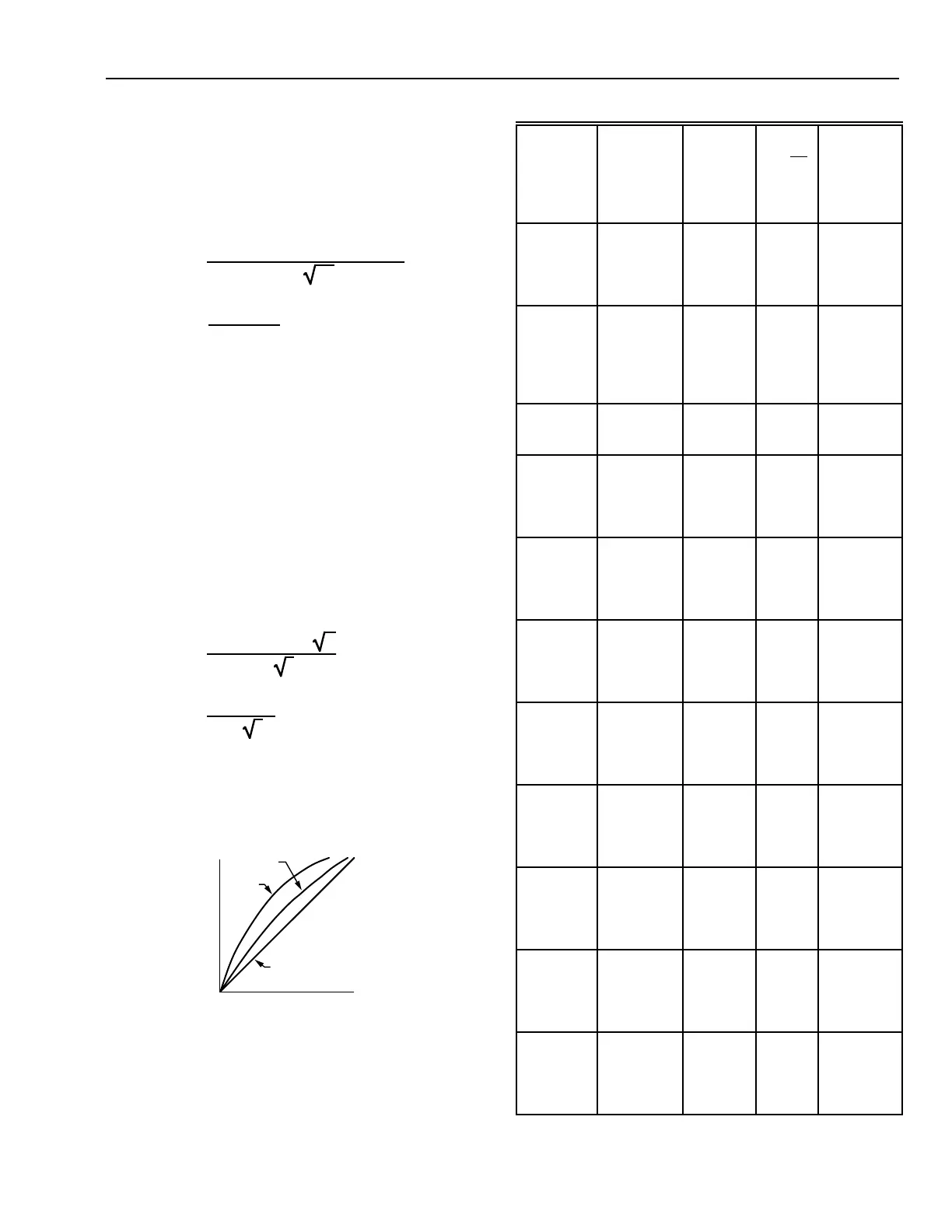

EXAMPLE 3:

Figure 20 shows the importance of selecting an 80 percent

pressure drop for sizing the steam valve in Example 2. This

pressure drop (5.6 psi) approximates the linear valve

characteristic. If only 30 percent of the available pressure

drop is used (0.30 x 6.96 psi = 2.10 psi or 2 psi), the valve

C

v

becomes:

C

v

=

(1 + 0.00075s)Q V

63.5 h

C

v

=

750 x 4.85

63.5 2

= 40.5

This larger valve (2 psi drop) has a steeper curve that is

further away from the desired linear valve characteristic.

See LINEAR VALVE under VALVE SELECTION for more

information.

Fig. 20. Effect of Pressure Drop in Steam Valve Sizing.

100%

0% 100%

STEM TRAVEL

VALVE OPENING/

STEAM FLOW

C2337

Cv = 41

Cv = 25

LINEAR VALVE

CHARACTERISTIC

(continued)

Table 5. Properties of Saturated Steam.

Loading...

Loading...