Model 3580A

and removing the four screws holding the pack

to the side

of

the instrument

chassis.

The

individual battery sticks may short

out

against

the sides

of

the instrument

if

the entire battery

pack

is

not

first removed.

7-32.

To

determine which battery stick

is

faulty, place the

3580A on CHARGE for 14 hours and then run the 3580A

on battery power until the undervoltage relays shut the

battery power off. (Good batteries will run for 5 hours

without a recharge). Measure the voltage across each

battery stick. The nominal voltage should

be

approximately

5 volts per stick. Test for the stick which

is

lower in voltage

than the other battery sticks. A bad stick will differ from

the other battery sticks

by

.5

or more volts.

7-33. The normal warranty period on batteries

is

90 days.

Proper operation implys that the battery, operated under

normal temperatures and load,

will

charge from a state

of

complete discharge in 14 hours, and

will

then power the

instrument for 5 hours

of

continuous and normal use.

7-34.

Cleaning

and

Lubricating

Rotary

Switches.

7-35. Faulty switches can cause intermittent performance,

spurious responses, noise, and many other annoying prob-

lems. Tests

have

shown that the typical operating life

of

a

switch

is

25,000 operations or more. With proper cleaning

and lubrication, this life may be extended to

as

much

as

100,000 or more operations. Freon TF cleaner (-hp- Part

No. 8500-0232)

is

available for cleaning switches. Electro-

tube 2G (-hp- Part No. 5060-6086)

is

available for lubricat-

ing high impedance switches. Electrotube 2A (-hp- Part No.

6040-0300)

is

available for lubricating low impedance

switches. Follow the instructions

given

with these cleaners,

-hp-

Service Note

M45B

(available from your local

-hp-

Sales and Service Office) also

gives

detailed information on

how

to

use

these cleaners.

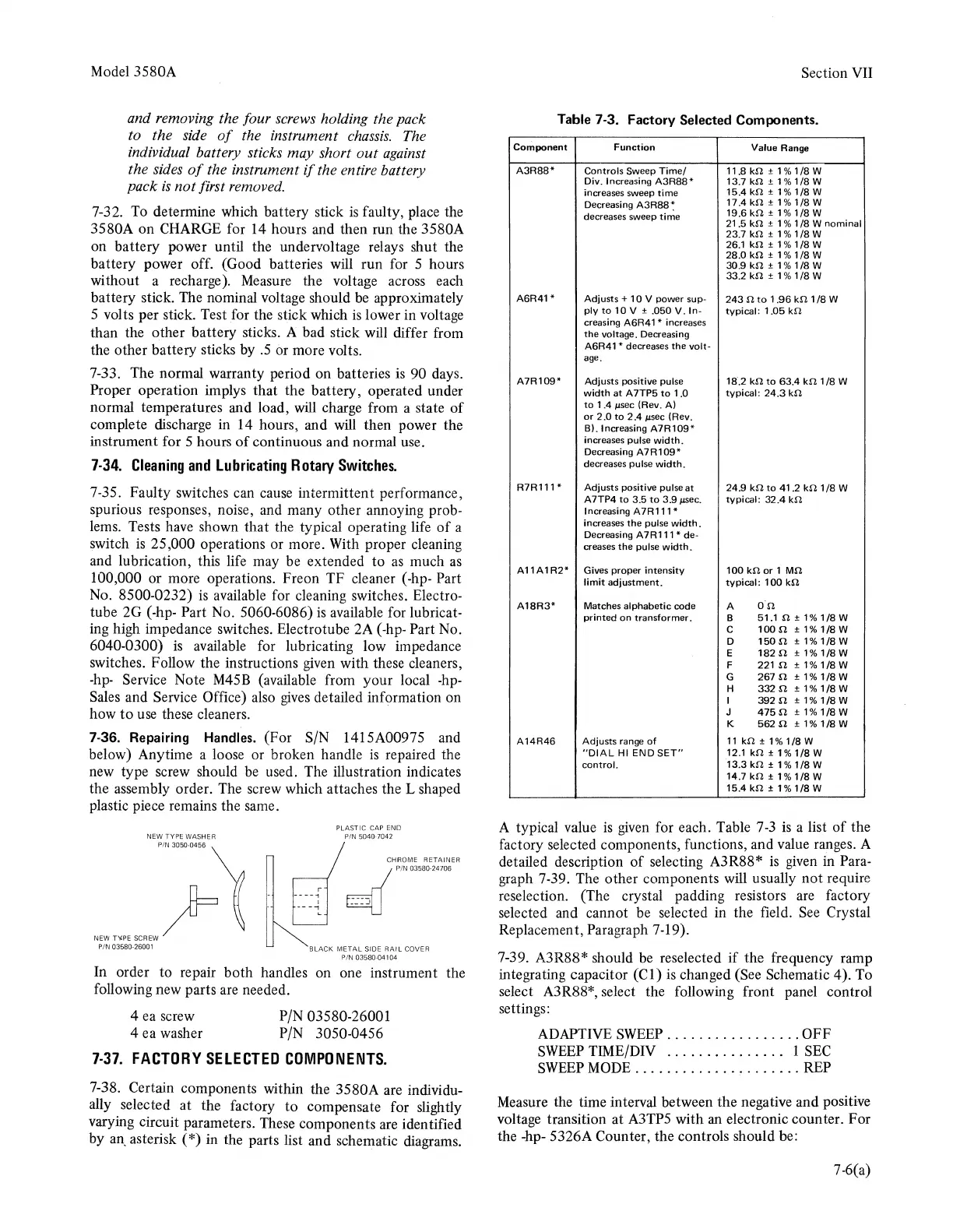

7-36. Repairing Handles. (For S/N 1415A00975 and

below) Anytime a loose or broken handle

is

repaired the

new type screw should

be

used. The illustration indicates

the assembly order. The screw which attaches the L shaped

plastic piece remains the same.

In order to repair both handles on one instrument the

following new parts

are

needed.

4 ea screw P/N 03580-26001

4 ea washer P/N 3050-0456

1·31.

FACTORY

SELECTED

COMPONENTS.

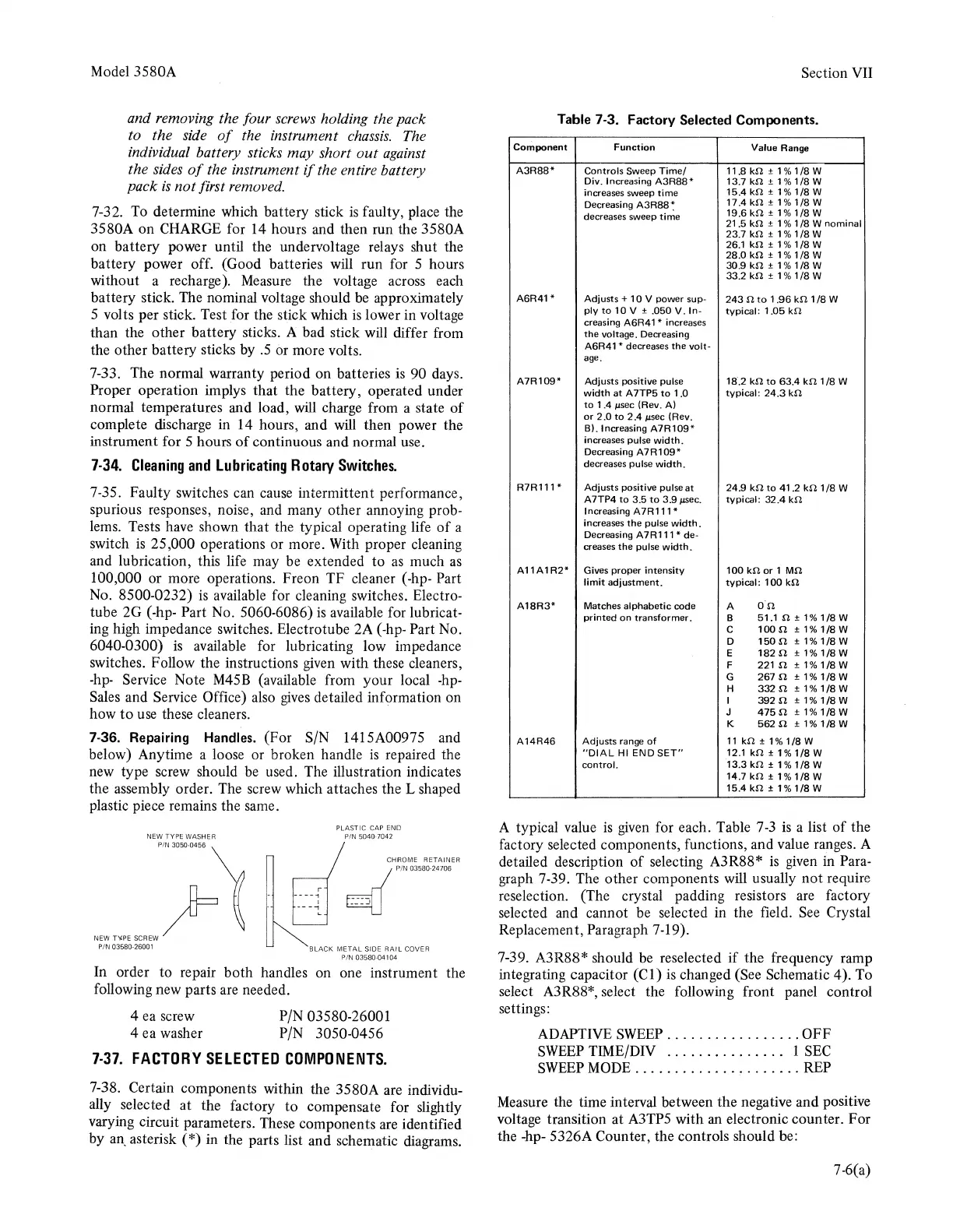

7-38. Certain components within the 3580A are individu-

ally selected

at

the factory

to

compensate for slightly

varying circuit parameters. These components are identified

by

an_

asterisk (*) in the parts list and schematic diagrams.

Section VII

Table

7-3. Factory Selected Components.

Component

Function

Value Range

A3R88*

Controls Sweep

Time/

11.8k.!1±1%1/8W

Div. Increasing

A3R88*

13.7k.!1±1%1/8W

increases sweep time

15.4k.!1±1%1/8W

Decreasing

A3R88:

17.4

k.!1±1%

1/8

w

decreases sweep time

19.6

k.!1±1%

1/8

w

21.5

k.!1±1%1/8

W nominal

23.7

k.!1

± 1%1

/8

w

26.1

k.!1±1%1/8W

28.0

k.!1

± 1 % 1

/8

w

30.9

k.!1±1%

1/8

w

33.2

k.!1

± 1 % 1

/8

w

A6R41*

Adjusts +

10

V power sup-

243

n

to

1 .96

kn

1

/8

W

ply

to

10

V ± .050

V.

In-

typical:

1 .05

k.!1

creasing

A6R41 *

increases

the

voltage. Decreasing

A6R41 *decreases the

volt-

age.

A7R109*

Adjusts positive pulse

18·.2

kn

to

63.4

kn

1

/8

w

width

at

A 7TP5

to

1 .0

typical:

24.3

k.!1

to

1.4

µsec

(Rev.

Al

or

2.0

to

2.4

µsec

(Rev.

BJ. Increasing

A7R109*

increases pulse width.

Decreasing

A7R109*

decreases pulse

width.

R7R111*

Adjusts positive pulse at

24.9

k.!1

to

41.2

k.!11/8 W

A7TP4

to

3.5

to

3.9

µsec.

typical:

32.4

k.!1

Increasing A7R111 *

increases

the

pulse

width.

Decreasing A7R111

*de-

creases

the pulse

width.

A11A1R2*

Gives proper

intensity

100k.!1or1

Mn

limit

adjustment.

typical:

100

k.!1

A18R3*

Matches alphabetic code

A

o·n

printed

on

transformer.

B

51.1.!1±1%1/BW

c

100

n ±

1%

1/8

w

D

1500

±1%1/8W

E

182fl±1%1/8W

F

221n±1%1/8W

G 267 n ±

1%

1/8

w

H

332S'l±1%1/8W

I

392

n ±

1%

1/8

w

J

4750±1%1/8W

K 562 n ±

1%

1/8

w

A14R46

Adjusts range

of

11

k!l±1%1/8W

"DIAL

HI

END

SET"

12.1k.!1±1%

1/8

w

control.

13.3

kn

± 1 % 1

/8

w

14.7

k.!1±1%

1/8

w

15.4

k.!1±1%

1/8

w

A typical value

is

given

for each. Table

7-3

is

a list

of

the

factory selected components, functions, and value ranges. A

detailed description

of

selecting A3R88*

is

given

in Para-

graph 7-39. The other components will usually not require

reselection. (The crystal padding resistors

are

factory

selected and cannot be selected in the field.

See

Crystal

Replacement, Paragraph 7-19).

7-39. A3R88* should

be

reselected

if

the frequency ramp

integrating capacitor

(Cl)

is

changed (See Schematic 4). To

select A3R88*, select the following front panel control

settings:

ADAPTIVE

SWEEP

.................

OFF

SWEEP

TIME/DIV . . . . . . . . . . . . . . . 1

SEC

SWEEP

MODE

.............

,

.......

REP

Measure the time interval between the negative and positive

voltage transition at A3TP5 with an electronic counter. For

the -hp- 5326A Counter, the controls should be:

7-6(a)

Loading...

Loading...