Service Procedures for the Gas Line

84 810440 Service Parts and Procedures Powermax65/85 SYNC

Install the air filter assembly

1. Remove the new air filter bowl and air filter element from the new air filter assembly.

2. Put the new air filter assembly into the plasma power supply.

3. Install the 3 screws on the rear panel. Tighten the

screws to 1.7 Nm (15 lbf·in).

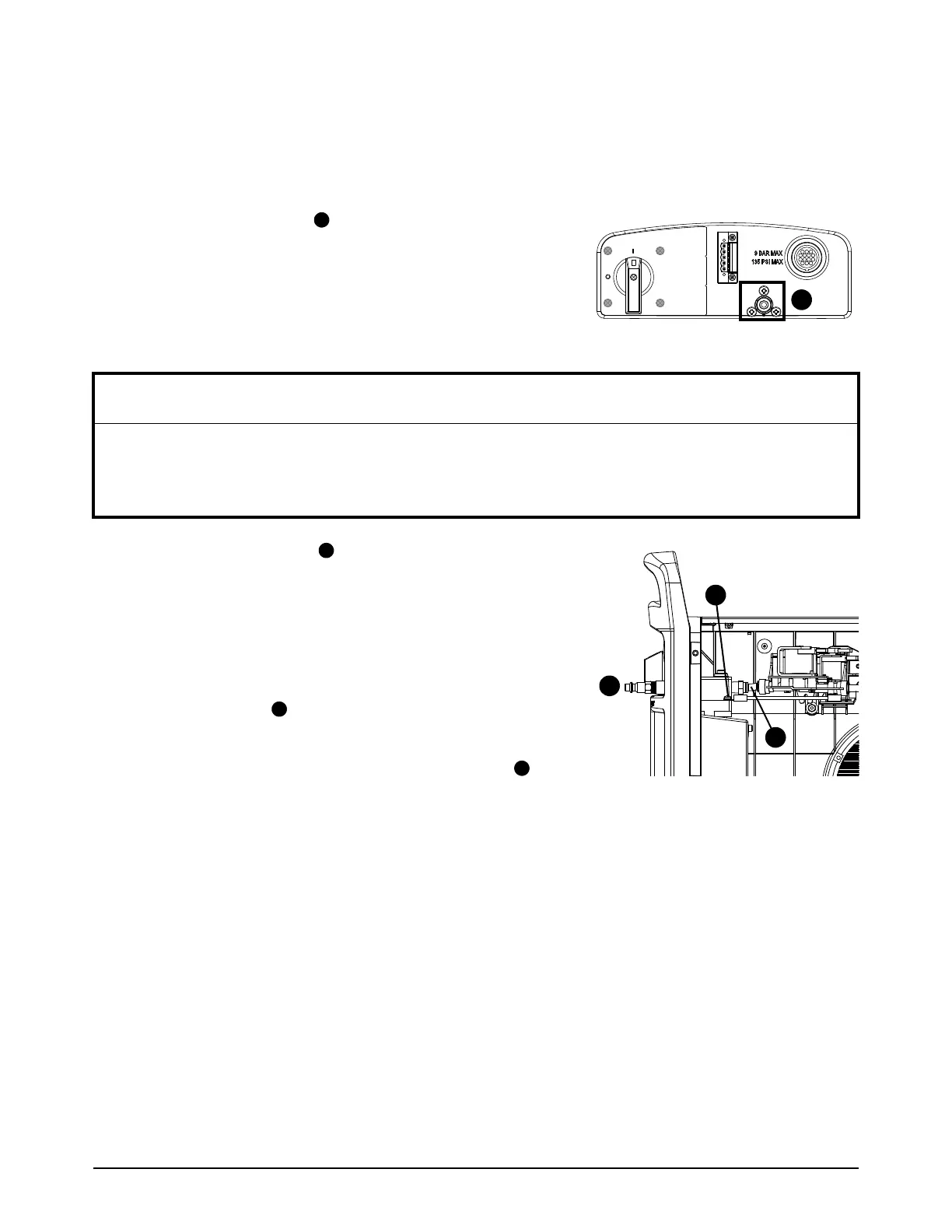

4. Apply a small amount of thread sealant to the threads of

the gas fitting.

Too much thread sealant can contaminate the gas

line.

5. Install the gas fitting onto the air filter assembly.

CSA models: Tighten the 1/4 NPT quick-disconnect

nipple to 10.2 N·m (90 lbf·in).

CE/CCC models: Tighten the G-1/4 BSPP adapter to

12.4 N·m (110 lbf·in).

6. Use the shortest gas tube in the kit. Push-to-connect the

new gas tube into the new air filter assembly and

solenoid valve.

7. Attach the ground wires with the ground screw .

Tighten the screw to 2.8 Nm (25 lbfin).

8. Install the new air filter bowl and air filter element. Refer to page 83.

9. Attach the rear panel. Refer to page 58.

10. Install the component barrier and the plasma power supply cover. Refer to page 51.

NOTICE

PTFE TAPE CAN CAUSE CLOGGED VALVES, REGULATORS, AND TORCHES

Never use PTFE tape on any joint preparation. Use only a liquid or paste thread sealant on male thread

ends.

Loading...

Loading...