20: PID INSTRUCTION

OPENNET CONTROLLER USER’S MANUAL 20-7

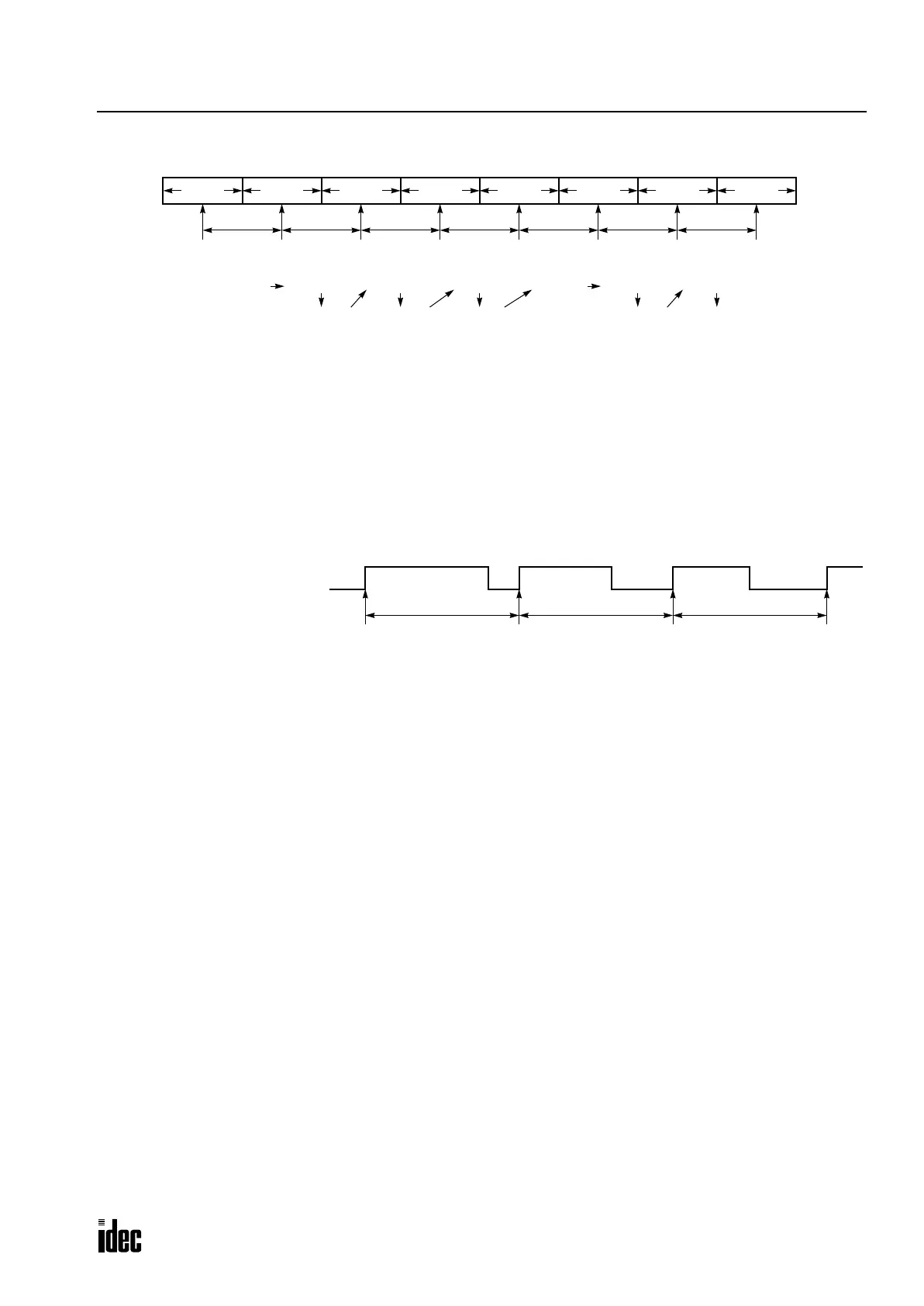

Example – Sampling period: 80 msec, Scan time: 60 msec (Sampling period > Scan time)

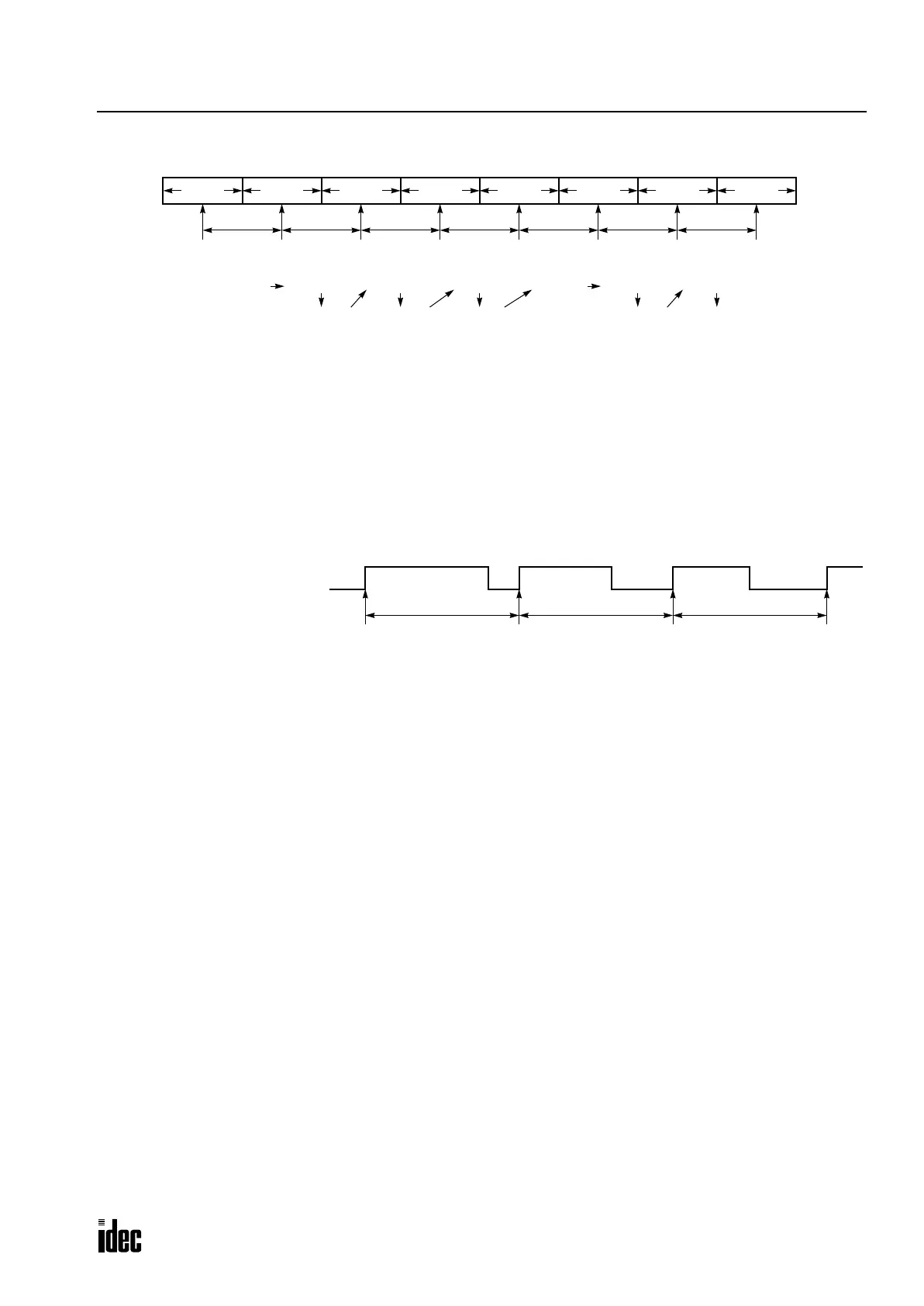

S1+13 Control Period

The control period determines the duration of the ON/OFF cycle of the control output (S2+6) that is turned on and off

according to the output manipulated variable (S1+1) calculated by the PID action or derived from the manual mode output

manipulated variable (S1+18). Set a required value of 1 through 500 to specify a control period of 0.1 sec through 50.0 sec

to the data register designated by S1+13. When S1+13 stores 0, the control period is set to 0.1 sec. When S1+13 is set to a

value larger than 500, the control period is set to 50.0 sec.

The ON pulse duration of the control output (S2+6) is determined by the product of the control period (S1+13) and the

output manipulated variable (S1+1).

Example – Control period: 5 sec (S1+13 is set to 50)

S1+14 High Alarm Value

The high alarm value is the upper limit of the process variable (S1+0) to generate an alarm. When the process variable is

higher than or equal to the high alarm value while the start input for the PID instruction is on, the high alarm output control

relay (S2+4) is turned on. When the process variable is lower than the high alarm value, the high alarm output control relay

(S2+4) is turned off.

When the linear conversion is disabled (S1+4 set to 0), set a required high alarm value of 0 through 4000 to the data regis-

ter designated by S1+14. When S1+14 stores a value larger than 4000, the high alarm value is set to 4000.

When the linear conversion is enabled (S1+4 set to 1), set a required high alarm value of –32768 through 32767 to the data

register designated by S1+14. The high alarm value must be larger than or equal to the linear conversion minimum value

(S1+6) and must be smaller than or equal to the linear conversion maximum value (S1+5). If the high alarm value is set to

a value smaller than the linear conversion minimum value (S1+6), the linear conversion minimum value will become the

high alarm value. If the high alarm value is set to a value larger than the linear conversion maximum value (S1+5), the lin-

ear conversion maximum value will become the high alarm value.

S1+15 Low Alarm Value

The low alarm value is the lower limit of the process variable (S1+0) to generate an alarm. When the process variable is

lower than or equal to the low alarm value while the start input for the PID instruction is on, the low alarm output control

relay (S2+5) is turned on. When the process variable is higher than the low alarm value, the low alarm output control relay

(S2+5) is turned off.

When the linear conversion is disabled (S1+4 set to 0), set a required low alarm value of 0 through 4000 to the data register

designated by S1+15. When S1+15 stores a value larger than 4000, the low alarm value is set to 4000.

When the linear conversion is enabled (S1+4 set to 1), set a required low alarm value of –32768 through 32767 to the data

register designated by S1+15. The low alarm value must be larger than or equal to the linear conversion minimum value

(S1+6) and must be smaller than or equal to the linear conversion maximum value (S1+5). If the low alarm value is set to

a value smaller than the linear conversion minimum value (S1+6), the linear conversion minimum value will become the

low alarm value. If the low alarm value is set to a value larger than the linear conversion maximum value (S1+5), the linear

conversion maximum value will become the low alarm value.

60 msec

1 scan

60 msec 60 msec 60 msec 60 msec 60 msec 60 msec

PID

60 msec (120 msec)

40 msec

(100 msec)

20 msec

80 msec

0 msec

60 msec (120 msec)

40 msec

(100 msec)

20 msec

1 scan 1 scan 1 scan 1 scan 1 scan 1 scan 1 scan

Executed

PID Not

Executed

PID

Executed

PID

Executed

PID

Executed

PID Not

Executed

PID

Executed

PID

Executed

5 sec

5 sec 5 sec

ON (4 sec) OFF ON (3 sec) ON (2.5 sec)OFF OFFOFFControl Output (S2+6)

80% 60% 50%Output Manipulated Variable (S1+1)

Control Period (S1+13)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...