20: PID INSTRUCTION

20-14 OPENNET CONTROLLER USER’S MANUAL

Application Example

This application example demonstrates a PID control for a heater to keep the temperature at 200°C.

In this example, when the program is started, the PID instruction first executes auto tuning according to the designated AT

parameters, such as AT sampling period, AT control period, AT set point, and AT output manipulated variable, and also the

temperature data inputted to the analog input module. The control output remains on to keep the heater on until the tem-

perature reaches the AT set point of 150°C. Auto tuning determines PID parameters such as proportional gain, integral

time, derivative time, and control action.

When the temperature reaches 150°C, PID action starts to control the temperature to 200°C using the derived PID param-

eters. The heater is turned on and off according to the output manipulated variable calculated by the PID action. When the

heater temperature is higher than or equal to 250°C, an alarm light is turned on by the high alarm output.

The analog input module data is also monitored to force off the heater power switch.

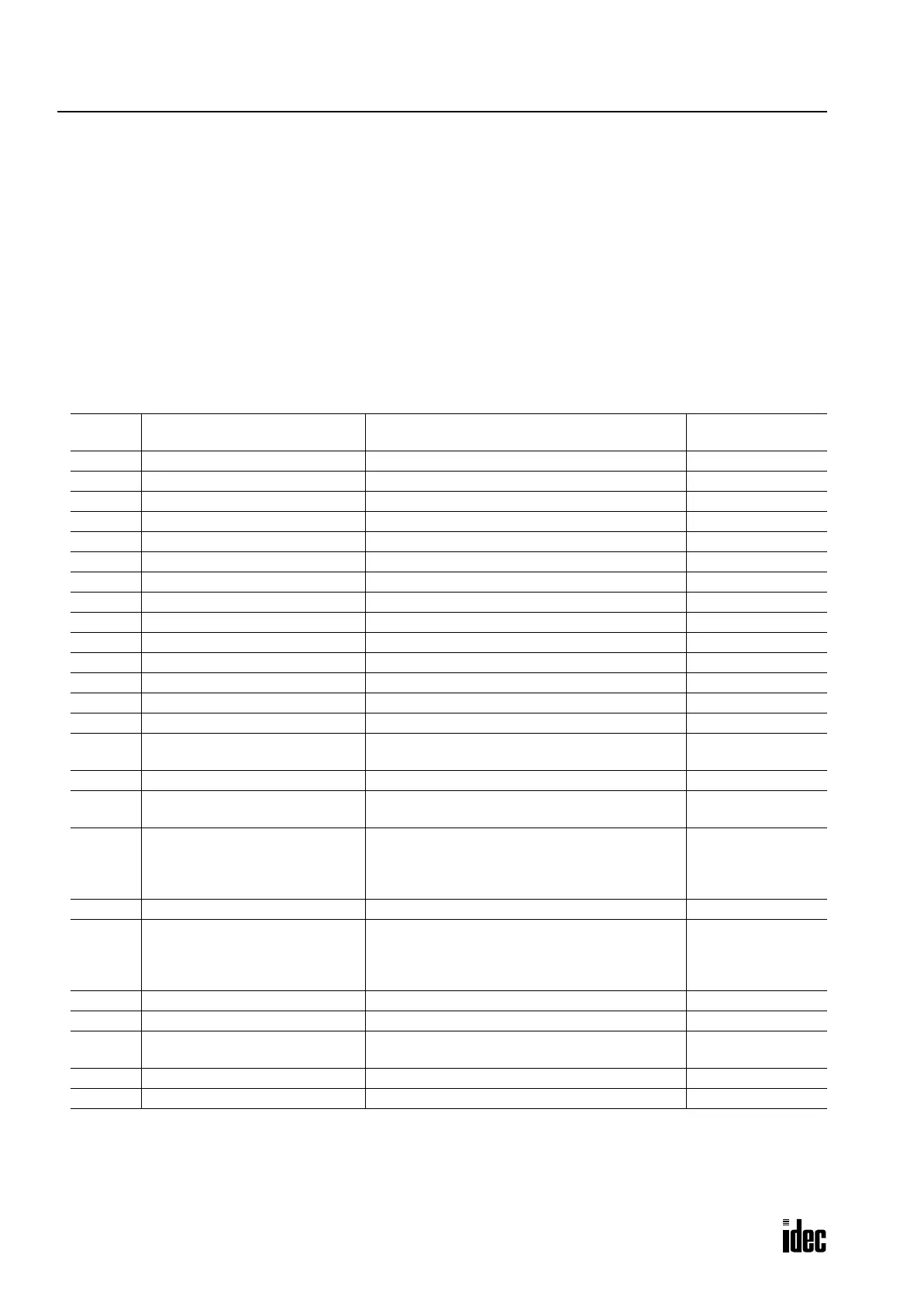

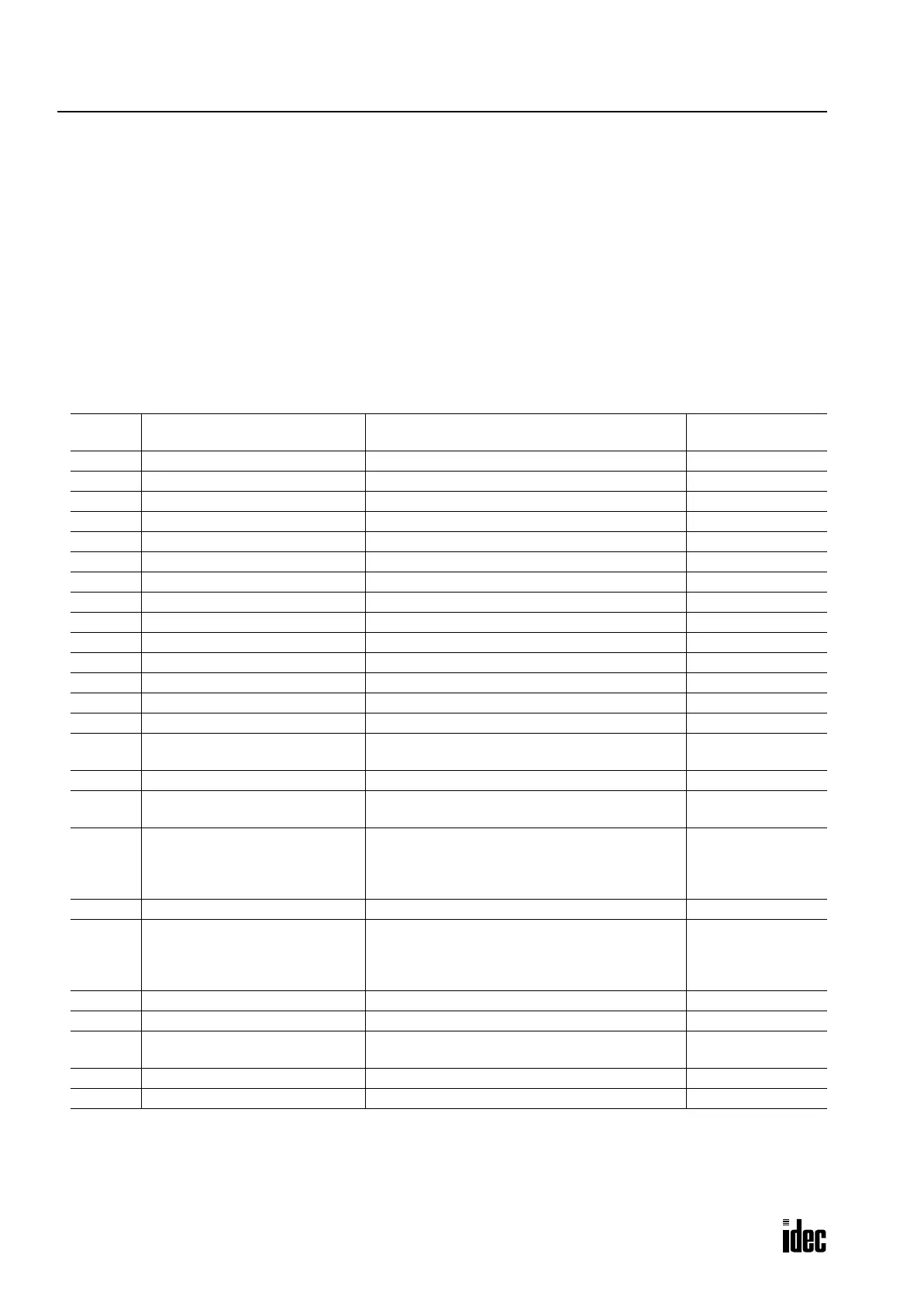

Operand Settings

Note: The output manipulated variable during auto tuning is a constant value. In this example, the AT output manipulated

variable is set to the maximum value of 100 (100%), so the control output (S2+6) remains on during auto tuning.

Operand Function Description

Allocation No.

(Value)

S1+3 Operation mode AT (auto tuning) + PID action D3 (1)

S1+4 Linear conversion Enable linear conversion D4 (1)

S1+5 Linear conversion maximum value 500°C D5 (5000)

S1+6 Linear conversion minimum value –50°C D6 (–500)

S1+10 Integral start coefficient 100% D10 (0)

S1+11 Input filter coefficient 70% D11 (70)

S1+12 Sampling period 500 msec D12 (50)

S1+13 Control period 1 sec D13 (10)

S1+14 High alarm value 250°C D14 (2500)

S1+19 AT sampling period 1.5 sec D19 (150)

S1+20 AT control period 3 sec D20 (30)

S1+21 AT set point 150°C D21 (1500)

S1+22 AT output manipulated variable 100% (Note) D22 (100)

S2+1 Auto/manual mode Auto mode M1 (OFF)

S2+2

Output manipulated variable limit

enable

Disable output manipulated variable limits M2 (OFF)

S2+3 Integral start coefficient disable Enable integral start coefficient (S1+10) M3 (OFF)

S2+4 High alarm output

ON: When temperature ≥ 250°C

OFF: When temperature < 250°C

M4

S2+6 Control output

Remains on during auto tuning;

Goes on and off according to the control period

(S1+13) and output manipulated variable (S1+1)

during PID action

M6

S3 Set point 200°C D100 (2000)

S4 Process variable

Analog input module is mounted at the first slot

among functional modules and the analog input

is connected to channel 0 of the analog input

module; stores 0 through 4000

L100

D1 Manipulated variable Stores PID calculation result (–32768 to 32767) D102

PID start input Starts to execute the PID instruction I0

Monitor input

Starts to monitor the analog input module data

for high alarm

I1

Heater power switch Turned on and off by control output M6 Q0

High alarm light Turned on and off by high alarm output M4 Q1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...