20: PID INSTRUCTION

OPENNET CONTROLLER USER’S MANUAL 20-15

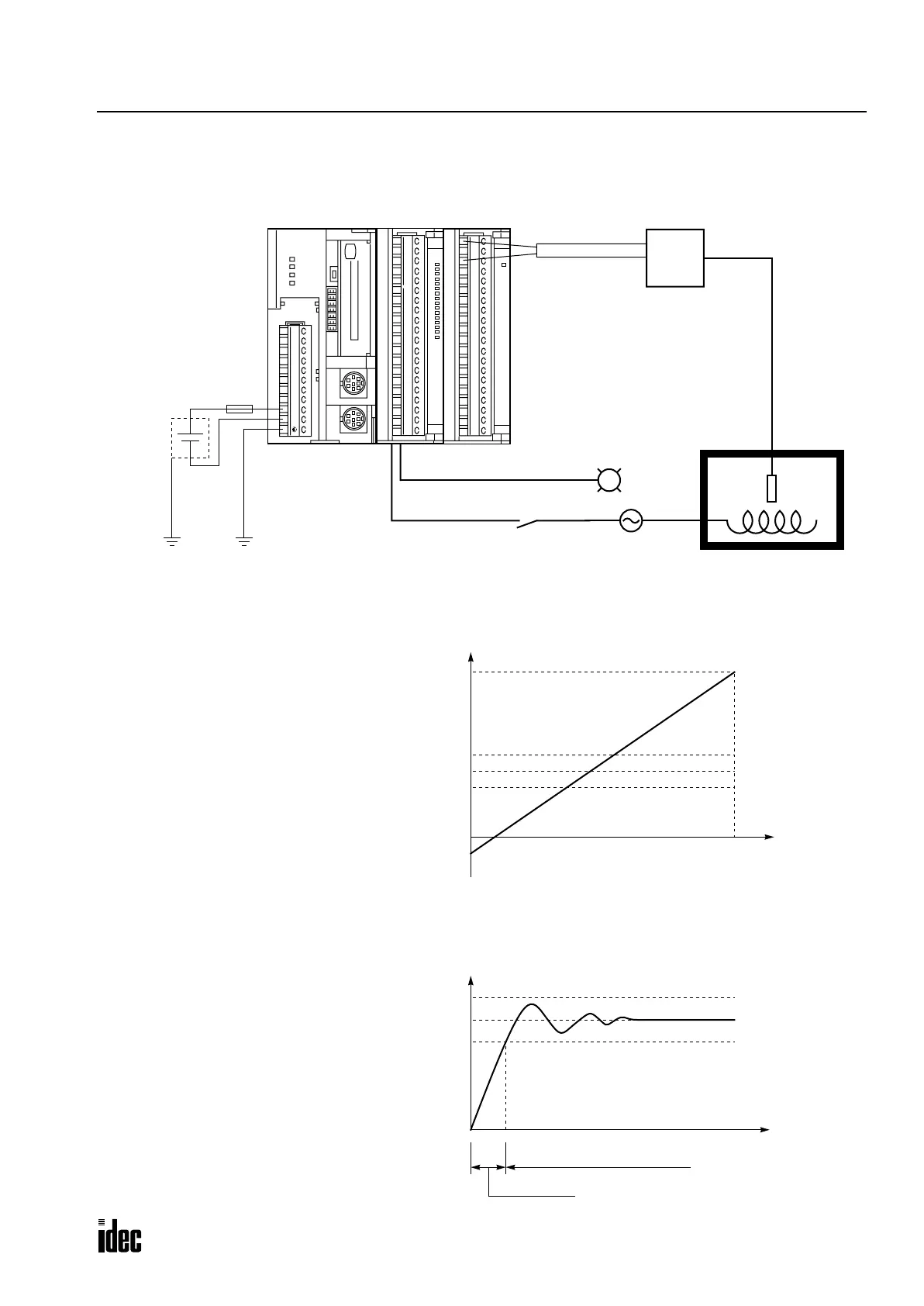

System Setup

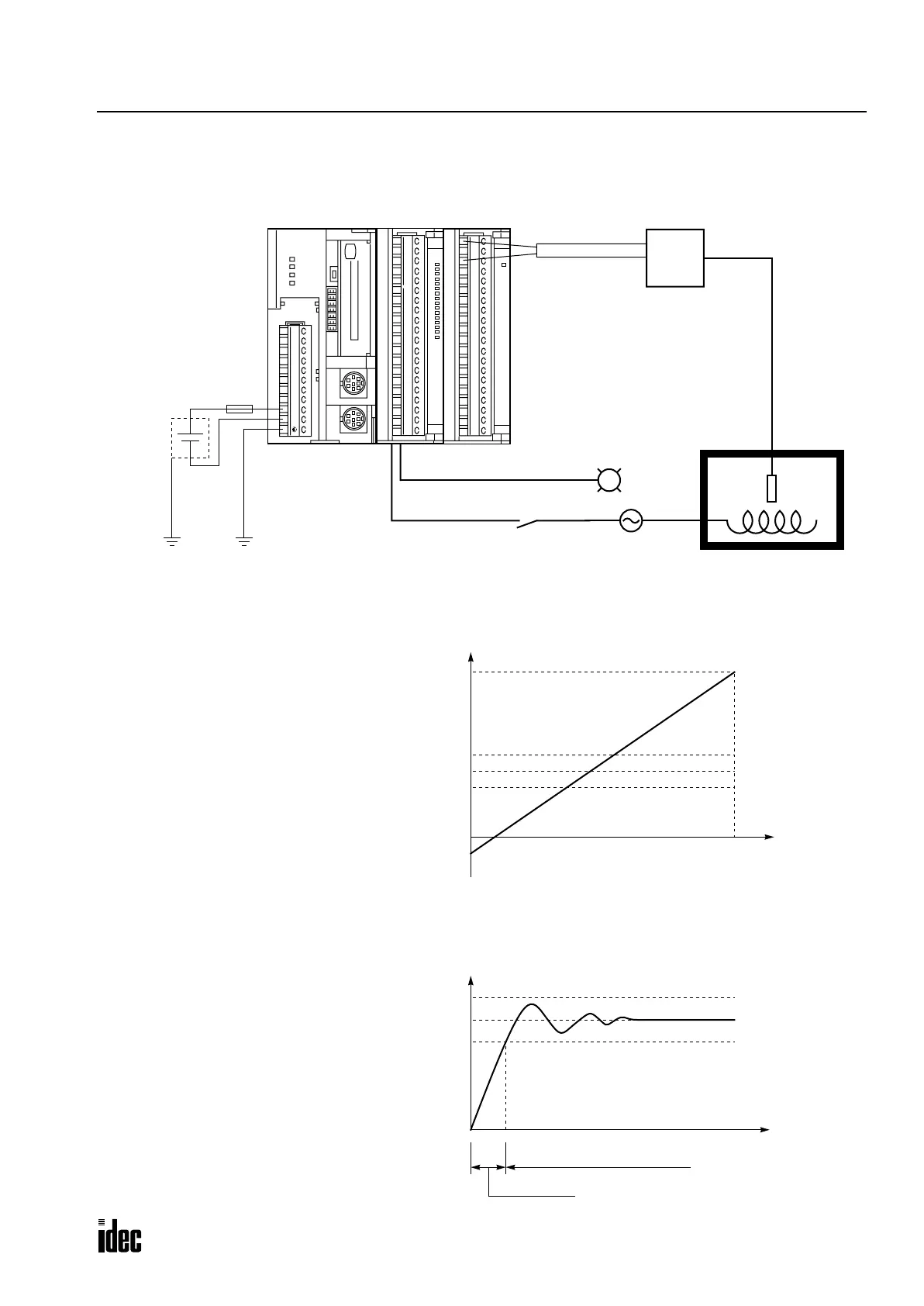

Digital Output from Analog Input Module vs. Process Variable after Conversion

Temperature Control by Auto Tuning and PID Action

ABG

RS485

COM A B Z

HSC

OUT

+24V 0V

POWER

RUN

ERROR

HSC OUT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A/D

+

_

24V DC

Fuse

CPU Module

Relay Output Module

FC3A-R161

Analog Input Module

FC3A-AD1261

0

1

2

3

4

5

6

7

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Ry

OUT

Transducer

–50° to 500°C

Thermocouple

High Alarm LightOutput Q1

Output Q0 Heater Power Switch

L

Heater

High Alarm Value (S1+14): 2500 (250°C)

4000

Linear Conversion Minimum Value (S1+6): –500 (–50°C)

0

Linear Conversion Maximum Value (S1+5): 5000 (500°C)

Set Point (S3): 2000 (200°C)

AT Set Point (S1+21): 1500 (150°C)

Digital Output from Analog Input Module

Process Variable after Conversion (S1+0)

Process Variable after Conversion (S1+0)

Time

High Alarm Value (S1+14): 2500 (250°C)

Set Point (S3): 2000 (200°C)

AT Set Point (S1+21): 1500 (150°C)

Auto Tuning

PID Action

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...