What to do if Intermec Printer has missing printhead dots?

- KKatherine MccoyAug 25, 2025

If your Intermec printer has missing printhead dots, you should replace the printhead.

What to do if Intermec Printer has missing printhead dots?

If your Intermec printer has missing printhead dots, you should replace the printhead.

What to do if Intermec EasyCoder PM4i printhead is failing?

If the printhead on your Intermec printer is failing, replace it.

What to do if Intermec EasyCoder PM4i printout is weaker on one side?

If the printout from your Intermec printer is weaker on one side, adjust the arm alignment.

How to fix weak spots on Intermec Printer?

If your Intermec printer shows weak spots, clean or replace the media.

Why is the print-out from my Intermec Label Maker so weak?

A weak print-out from your Intermec Label Maker can stem from several causes. It could be due to using the wrong paper type or having a contrast value that is too low, both of which require you to change the parameter. Alternatively, the printhead pressure might be too low, necessitating an adjustment. In more serious cases, the printhead may be worn, requiring replacement, or the printhead voltage could be incorrect, which would require replacing the CPU board.

Why is my Intermec Label Maker printing too dark?

An overall dark print-out from your Intermec Label Maker can be caused by several factors. The paper type might be incorrect, or the contrast value could be set too high; in both cases, you should change the parameter. Also, the printhead pressure could be too high, requiring adjustment. In some instances, the printhead voltage might be wrong, which means the CPU board needs to be replaced.

How to fix media feed that is not working properly in my Intermec Label Maker?

If the media feed isn't working correctly on your Intermec Label Maker, consider these potential causes: * If you've changed media characteristics, perform a TEST-FEED. * Incorrect start- and stop adjust values, Media Type parameter, or LSS position may be the issue, so check/change these settings. * Dirty sensors can also cause this problem, so clean the media guides. * Faulty sensors may require replacement.

Why is the print-out from my Intermec Label Maker overall weak?

An overall weak print-out from your Intermec Label Maker can be caused by several factors: the wrong media grade, a contrast value that is too low, printhead pressure that is too low, a worn printhead, or the wrong printhead voltage. You may need to change a parameter, adjust the printhead pressure, or replace the printhead or CPU board to fix this.

How to fix white vertical lines on Intermec Printer?

If you are experiencing white vertical lines on your Intermec printer, try cleaning the printhead.

What causes media feed not working properly on Intermec Label Maker?

If the media feed is not working properly on your Intermec Label Maker, it could be due to changed media characteristics, an incorrect label rest dots parameter, a wrong Media Type parameter, a wrong LSS position, dirty sensors, or faulty sensors. Try pressing the Print button, checking or changing parameters, cleaning the media guides, or replacing the sensors.

Provides essential safety warnings and precautions for operating Intermec equipment.

Explains the meaning of various warning and caution icons used in the document.

Details warranty information and how to access web and telephone support.

Lists services and contact options for technical support and product ordering.

Identifies the target audience and lists how to download or order additional Intermec documentation.

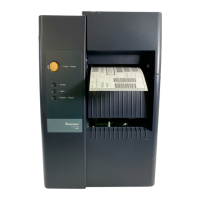

Details the specifications, features, and capabilities of the EasyCoder PM4i printer.

Summarizes critical safety warnings and how to identify the printer's model and serial number.

Describes the components and features visible on the front panel of the printer.

Details the connectors, switches, and slots located on the rear panel of the printer.

Explains the media compartment, supply roll post, and print mechanism for loading and printing.

Explains how to connect the printer to power and a computer via various interfaces.

Introduces the printer's interface elements like indicator lamps, display, keyboard, and beeper.

Explains startup files, memory card usage, and printer behavior on power-on.

Provides a step-by-step guide on how to power on the printer and its initialization process.

Describes common media loading methods like Tear-Off, Peel-Off, and Cut-Off.

Explains loading media using external supplies like fanfolds or rotating hubs.

Guides the user on how to load the thermal transfer ribbon correctly for printing.

Details how to enter and navigate Setup Mode, and configure parameters via Fingerprint/Direct Protocol.

Controls communication parameters for serial ports, including baud rate, parity, and flow control.

Configures media feed adjustments and media characteristics for optimal print quality.

Sets print speed, tests, and sensor adjustments for print quality.

Provides methods to reset all printer setup parameters to their original factory defaults.

Explains how to enter and navigate the printer's Setup Mode using the keyboard and display.

Introduces Intermec Shell, how to start it, and select applications or facilities.

Details the Line Analyzer program for diagnosing communication problems by capturing and printing data.

Describes how adding options enhances the printer's flexibility for various applications.

Details options like liner takeup, paper cutter, media hubs, sensors, and retainers for media management.

Covers options for keyboards, RFID kits, printheads, and various interface boards.

Explains the IRI status and lists error messages with their meanings for troubleshooting.

Provides a guide to common print quality symptoms, their possible causes, and suggested remedies.

Details printhead cleaning and cleaning the media guides for optimal print quality and longevity.

Explains safe external cleaning and procedures for clearing media jams.

Provides instructions on how to safely replace the printer's printhead.

Guides on adjusting for narrow media and aligning the Label Stop Sensor (LSS).

Explains how to adjust printhead pressure and ribbon break shaft for optimal performance.

Explains how to adjust the sensitivity of the Label Taken Sensor (LTS).

Lists technical data for printing, modes of operation, firmware, physical measures, and electronics.

Details printer controls, data interfaces, and available accessories and options.

Provides specifications for media roll sizes and details for various media types like labels and tickets.

Details the RS-232 interface protocol and pinout, and the printer's USB support.

Explains the bar code wand interface and lists optional interface boards for expanded connectivity.

Lists Intermec's direct thermal and thermal transfer media, and transfer ribbons for various applications.

Provides recommended paper type settings by region and explains bar code printing directions.

Provides detailed setup overviews for serial communication ports UART1 through UART5.

Details network communication setup for NET1 and RFID configuration options.

| Print technology | Direct thermal |

|---|---|

| Maximum resolution | 203 x 203 DPI |

| Display | LCD |

| Product color | Silver |

| Standard interfaces | RS-232, USB 2.0 |

| Internal memory | 16 MB |

| Media thickness | 2.5/8.7 mm |

| Maximum label width | 114.3 mm |

| Maximum label length | 4 m |

| Maximum roll diameter | 213 mm |

| Maximum internal memory | 1 GB |

| Supported network protocols | TCP/IP, LPR/LPD, FTP, BOOTP, DHCP, HTTP, SNMPv3, SMTP, SNMP-MIB II |

| Power requirements | 90 - 265 VAC, 45 - 65Hz |

| Power consumption (standby) | 15 W |

| Power consumption (printing) | 125 W |

| Storage temperature (T-T) | -20 - 70 °C |

| Operating temperature (T-T) | 40 - 104 °F |

| Operating relative humidity (H-H) | 20 - 80 % |

| Depth | 543 mm |

|---|---|

| Width | 298 mm |

| Height | 261 mm |

| Weight | 13500 g |