JOHNSON CONTROLS

106

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

SECTION 5 – SEQUENCE OF OPERATION

FLEXSYS

• FlexSys is a unit conguration used for HVAC

systems that utilize an underoor plenum to de-

liver conditioned air to a space.

• The FlexSys conguration allows the Series 100

unit to operate in a manner that best suits an un-

deroor HVAC system.

• It is recommended that a Series 100 unit cong-

ured for FlexSys operation be paired with other

components in the Johnson Controls underoor

air distribution (UFAD) system product line for

optimum comfort and building control.

• A FlexSys unit needs to have a return air bypass

duct and damper installed for proper operation.

• The unit is similar to a standard VAV system, but

the conditioned air is delivered to the space from

under the oor instead of from overhead ductwork

through VAV boxes.

• The underoor plenum may or may not have un-

deroor boxes that allow the air up into the space.

• Most sequences on a FlexSys unit operate in the

same manner as a VAV unit.

• The cooling sequences and some specialized se-

quences differ from a VAV unit.

Basic FlexSys System Design

• The design of a FlexSys HVAC system is very crit-

ical to the proper operation of the Series 100 unit.

• Please review the following areas that create is-

sues with the proper operation of a FlexSys unit

and overall UFAD performance.

1. Plenum Integrity

• “If you make a hole, seal a hole.”

• The underfloor plenum needs to be com-

pletely sealed to prevent the conditioned air

from escaping.

2. Open Plenum Returns

• Johnson Controls engineers recommend

avoiding open plenum return for a UFAD.

• Return air should be ducted to the space

whenever possible.

3. Six Foot Cooling Zone

• When designing for a UFAD, only the first 6

feet up from the floor should be conditioned.

• The remaining area above 6 feet is used to

allow the air to mix with various heat loads

in the space.

• This mixing of air helps to ensure warm enough

return air to use in the return air bypass duct.

• Johnson Controls engineers have found during

extensive testing that RATs cooler than 78.0°F

cannot properly raise the temperature of the air

leaving the evaporator coil to the recommend-

ed mixed SAT of 62.0–64.0°F. The engineers

found that mixed SATs lower than 62.0°F are

uncomfortable to occupants of a space.

4. Multiple Plenums/One Unit

• When designing for a UFAD where one unit

services different plenums, it is recommended

that each separate plenum have its own vol-

ume damper controlled by an actuator.

• Each plenum should also have its own pressure

transducer that controls the actuator driven vol-

ume damper.

• Each separate plenum should be maintained at

0.05 iwg.

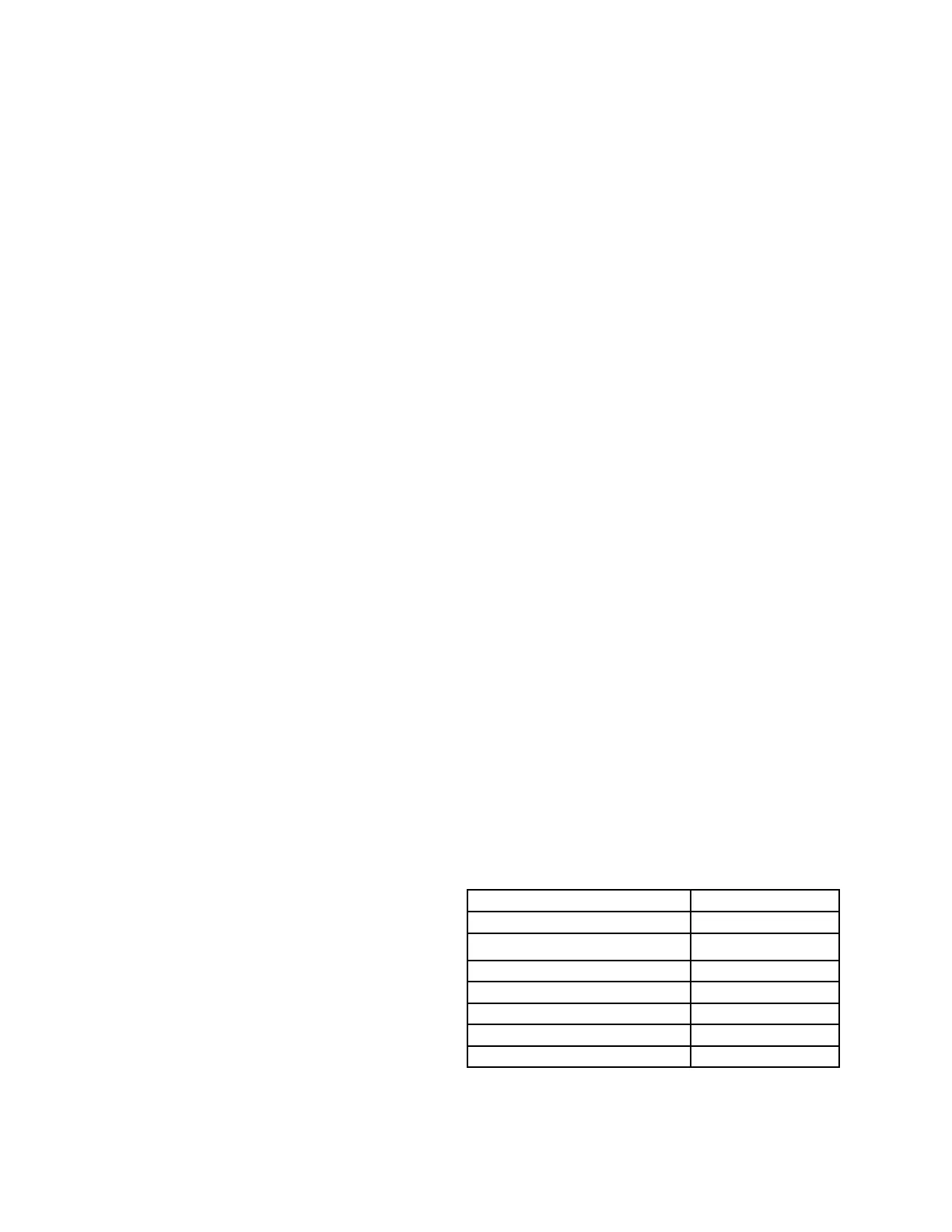

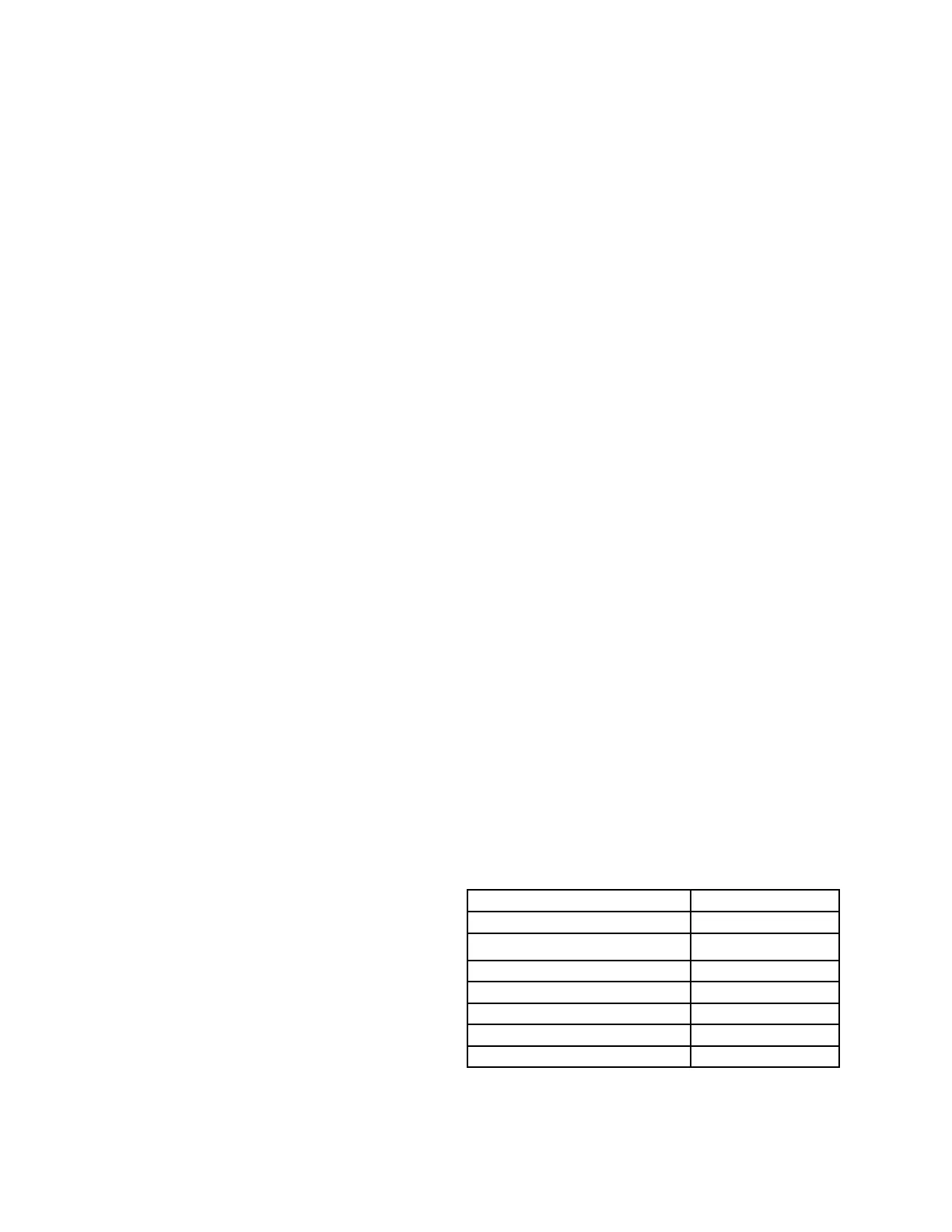

Factory Recommended Setpoints

• Since a FlexSys unit delivers air through an un-

deroor plenum, some of the setpoints differ from

a typical VAV unit.

• Table 39 on page 106 shows recommended set-

points provided by the engineering team, which are

supported by extensive testing and research.

• However, these are recommendations only and

job-specic setpoints could differ. Johnson Con-

trols recommends using these setpoints as a start-

ing point.

TABLE 39 - RECOMMENDED SETPOINTS

SETPOINT TEMPERATURE (°F)

RAT Cooling 78.0°F

Mixed SAT 62.0–64.0°F

EAT High 58.0°F

EAT Low 55.0°F

Duct Static 0.05 inch-WC

Heating SAT 80.0°F

Max Bypass 40%

NOTE:

On a FlexSys unit, the mixed SAT is the temperature of the supply

air off the evaporator coil mixed with the warmer return air that is

bypassed around the evaporator coil. The bypassed return air is

introduced directly under the supply air fan.

Loading...

Loading...