JOHNSON CONTROLS

90

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

SECTION 5 – SEQUENCE OF OPERATION

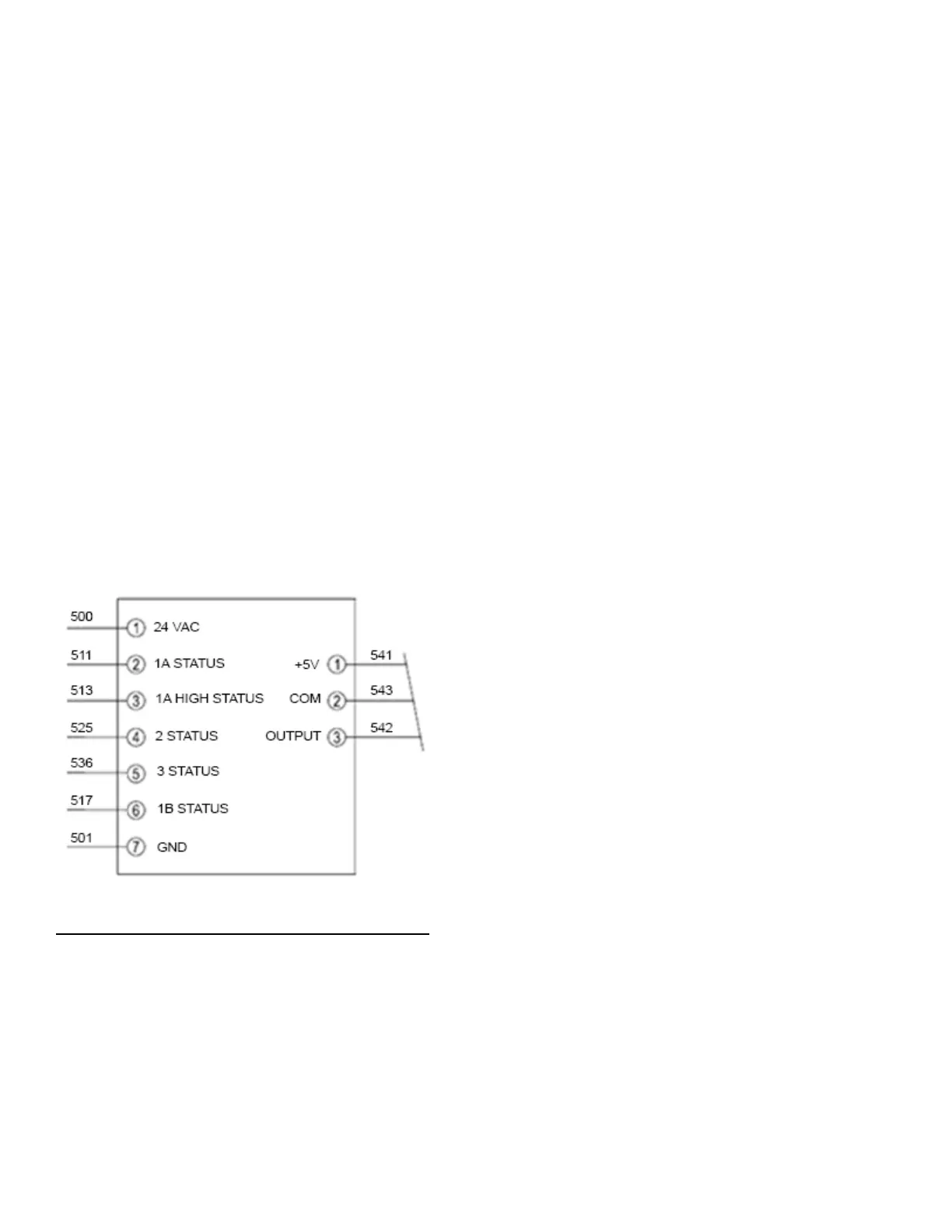

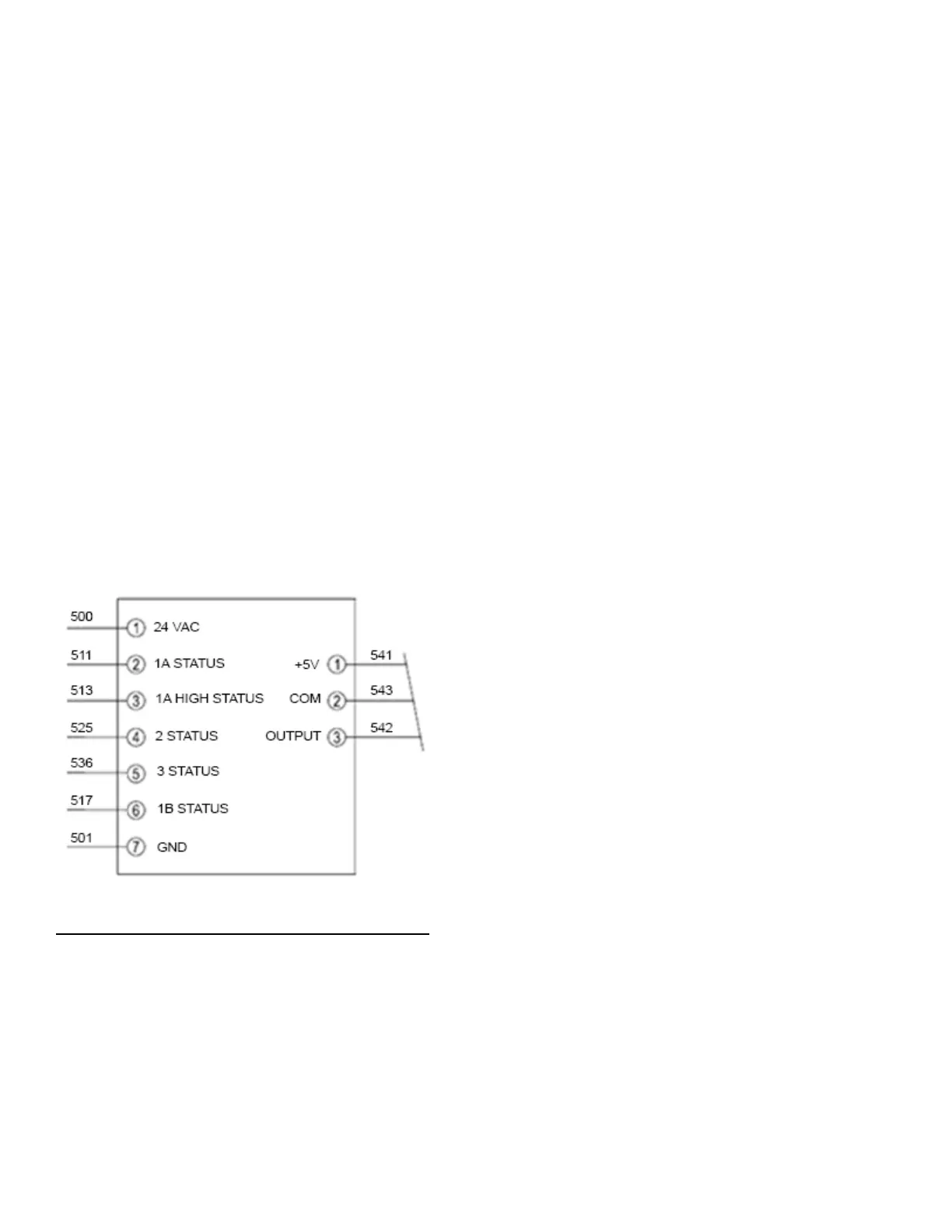

• Sends 24 VAC to the digital multiplexor con-

trol, which sends a 0–5 VDC signal back to

the IPU board. This 0–5 VDC signal proves

furnace 1A status is good.

• Once the IPU board receives the appropriate VDC

signal from the digital multiplexer control, the IPU

board removes 24 VAC from the 6R relay, which

causes:

1. The induced draft motor to switch to low speed

2. The modulating gas valve to switch to mini-

mum low fire

• Furnace 1A is now in Modulation mode.

• When ame rectication is not established, the ig-

nition control removes the high voltage spark and

24 VAC from the gas valve, waits 30 seconds, and

then tries again.

• The ignition sequence is tried three times. When a

ame is not established by the third try, the igni-

tion control locks out for 1 hour.

• Furnace sections 2, 3, and 1B follow the same se-

quence as staged gas heat.

LD21613

FIGURE 47 - DIGITAL MULTIPLEXOR

CONNECTIONS FOR MODULATING GAS HEAT

Modulating Operation

• Once Furnace 1A has successfully ignited, the

IPU board enters the normal modulating heat se-

quence.

• On a modulating gas heat unit. furnace 1A is al-

ways the rst ON and last OFF.

• Furnace 1A has a 2 stage gas valve and a modu-

lating gas valve controlled by a Maxitrol

®

Signal

Conditioner.

• The signal conditioner receives a 0–10 VDC sig-

nal from the IPU board depending on the required

heating demand.

1. Furnace 1A Low Fire

• Furnace 1A starts with the low fire solenoid of

the 2 stage gas valve being energized.

• Modulating gas valve at minimum position

at approximately 0.5–2 VDC from the IPU

board.

• The inducer motor is on low speed.

• When the heating demand increases, the

0–10 VDC signal increases, which further

opens the modulating valve.

• When the heating demand decreases, the

0–10 VDC signal decreases, which closes the

modulating gas valve.

• Modulating gas valve is at maximum posi-

tion at approximately 6.5 VDC from the IPU.

• When more heat is needed, furnace 1A

switches to high fire.

2. Furnace 1A High Fire

• The IPU energizes the high fire solenoid of

the 2 stage gas valve.

• Modulating gas valve at minimum position,

approximately 4–4.5 VDC from the IPU

board.

• The inducer motor switches to high speed.

• When the heating demand increases, the

0–10 VDC signal increases, which further

opens the modulating valve.

• When the heating demand decreases, the

0–10 VDC signal decreases, which closes the

modulating gas valve.

Loading...

Loading...