JOHNSON CONTROLS

53

SECTION 4 – MAINTENANCE

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

4

LD06354

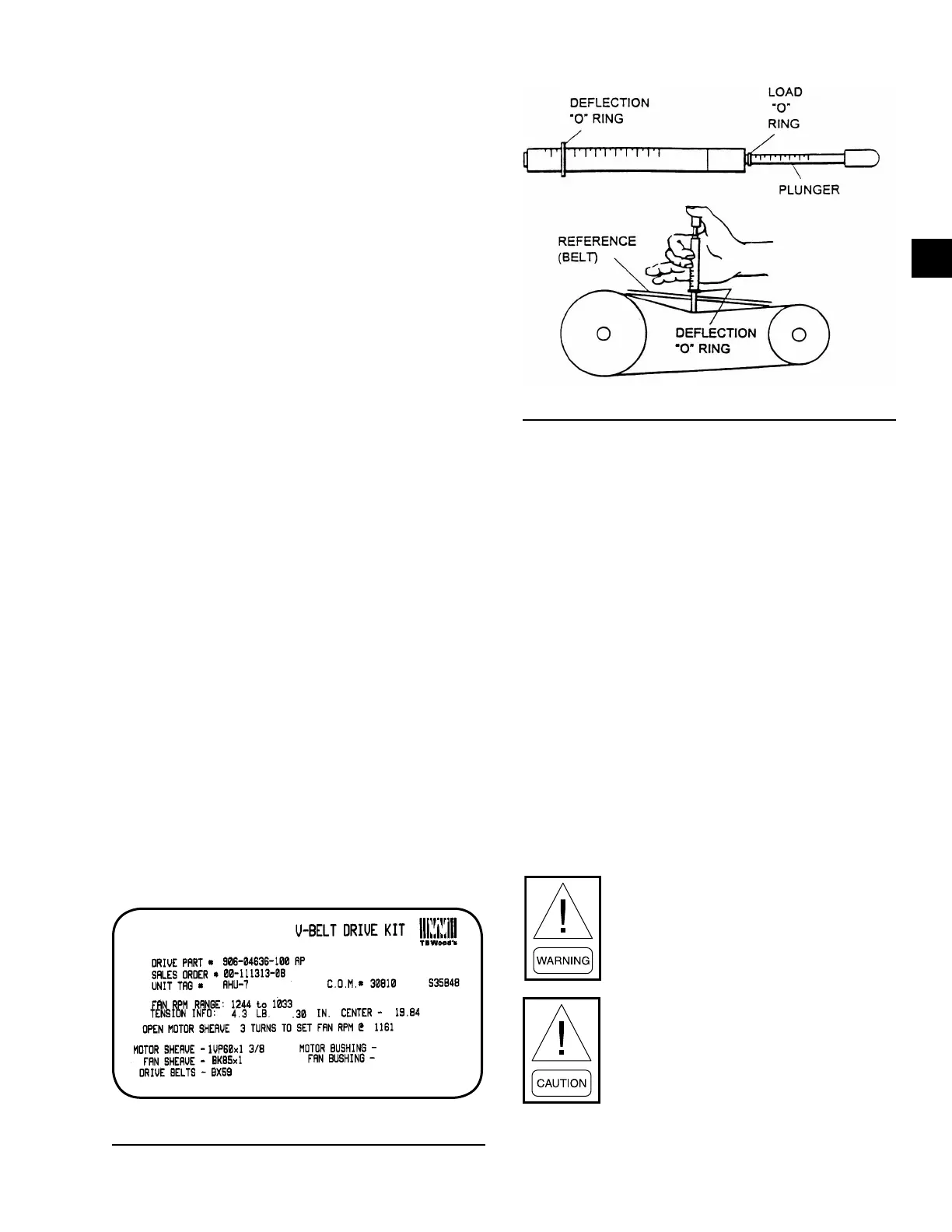

FIGURE 19 - BELT TENSIONING GAUGE

Filter Drier Replacement

The filter/drier should be replaced any time work is

performed on the refrigerant circuit. The rooftop unit

comes with sealed type (non-replaceable) cores as

standard. If the unit is not equipped with the option-

al valve package (suction, discharge, and liquid line

valves); the refrigerant will need to be recovered with

a recovery machine to replace the filter/drier.

If the unit is equipped with a valve package, the unit

can be pumped down by closing the liquid line ball

valve (prior to the filter/drier) while the unit is run-

ning, initiating a unit pump-down. The unit will shut

off when the mechanical low-pressure switch opens.

When the unit shuts down, close the ball valve located

after the filter/drier and remove power from the unit

to prevent the unit from running. Once the filter/drier

core has been replaced, the filter/drier section should

be evacuated via the Schrader access valve located

next to the filter/drier prior to opening the ball valves

and restoring the unit to normal operation.

Never shut the discharge valve while the

unit is running. Doing so could cause a

rupture in the discharge line or compo-

nents, resulting in death or serious injury.

Never close the suction line ball valve with

the compressor running. Doing so will

cause the compressor to pump-down into

a vacuum and damage the compressor due

to internal arcing.

Belts

New belts should be re-checked after 24 hours of op-

eration. On multiple belt adjustable pulleys, the pitch

depth should be checked to insure identical belt travel,

power transfer and wear. Adjustable motor bases are

provided for belt adjustment.

Motor pulleys and blower shaft pulleys are locked

in position with either set screws or split taper lock

bushings. All set screws and/or taper lock bolts must

be checked for tightness and alignment before putting

equipment into operation.

An incorrectly aligned and tensioned belt can substan-

tially shorten belt life or overload blower and motor

bearings, shortening their life expectancy. A belt ten-

sioned too tightly can overload the motor electrical,

causing nuisance tripping of the motor overloads and/

or motor failure and/or shaft failure.

Belt Replacement

Always replace belts as a set. Follow the steps below

to replace belts:

1. Release the tension on the belts by loosening the

adjusting nuts on the fan motor.

2. Remove old belts and recheck the sheave align-

ment with a straight edge.

3. Install the new belts on the sheaves.

Never place the belts on the sheaves by using a screw-

driver to pry the belt over the rim of the sheave. This

will permanently damage the belts.

Belt Tensioning

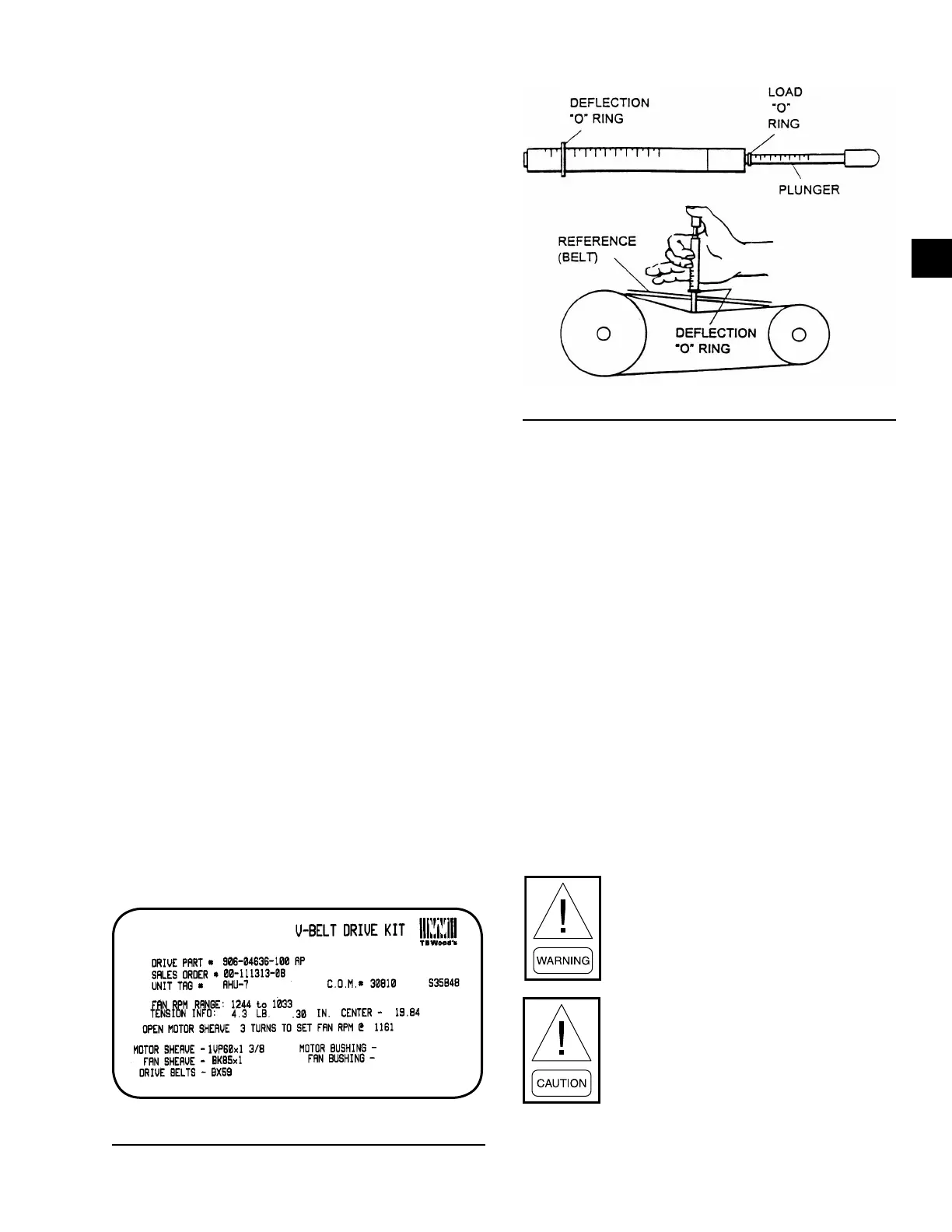

Belt tension information is included on the fan skid data

plate as shown in Figure 18 on page 53. Sample data

plate shows 4.3 lbs pressure at .30-inches deflection.

A Browning Belt tension gauge is used in Figure 19 on

page 53 to properly tension belts.

00494vip

FIGURE 18 - FAN DATA PLATE - BELT TENSION

Loading...

Loading...