JOHNSON CONTROLS

73

SECTION 5 – SEQUENCE OF OPERATION

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

5

LD28117

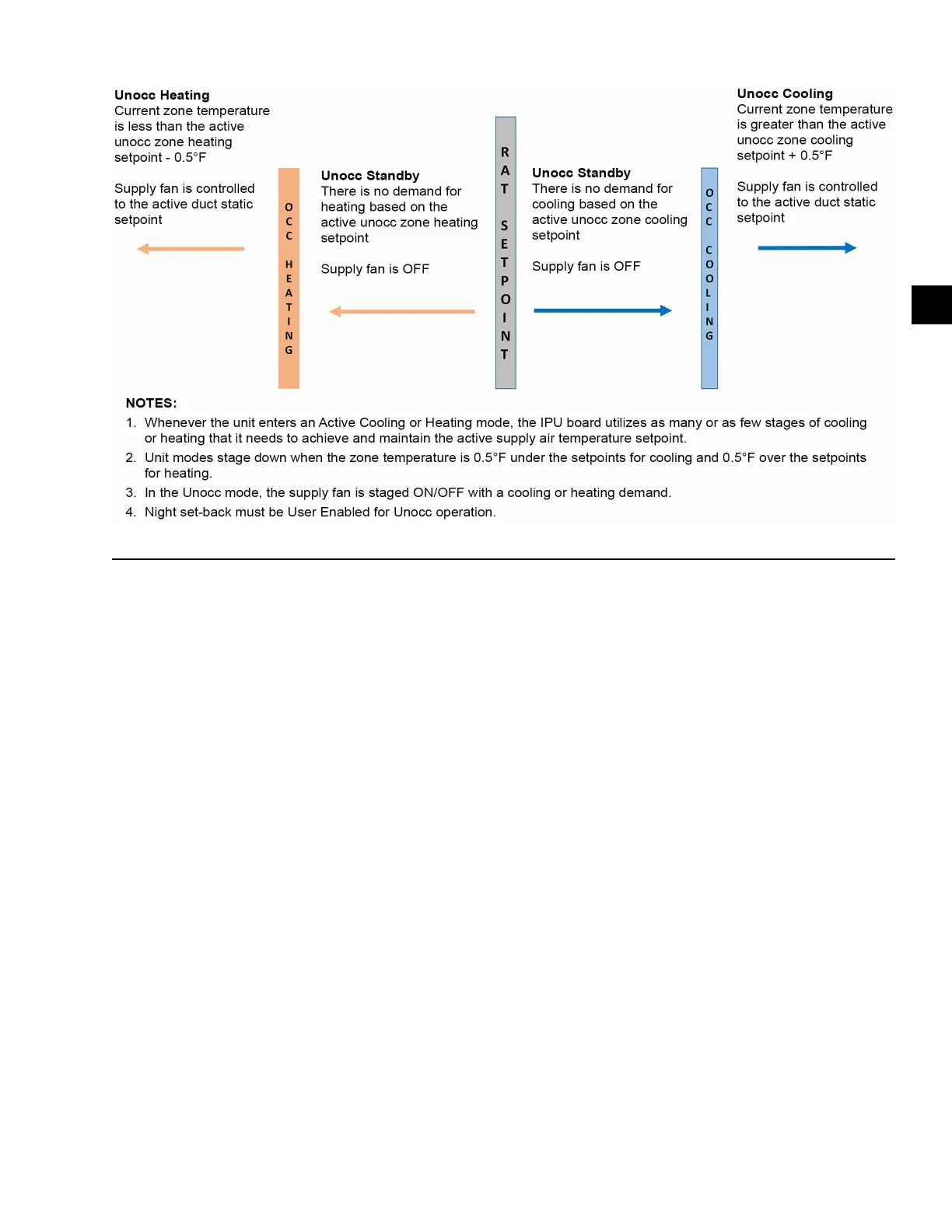

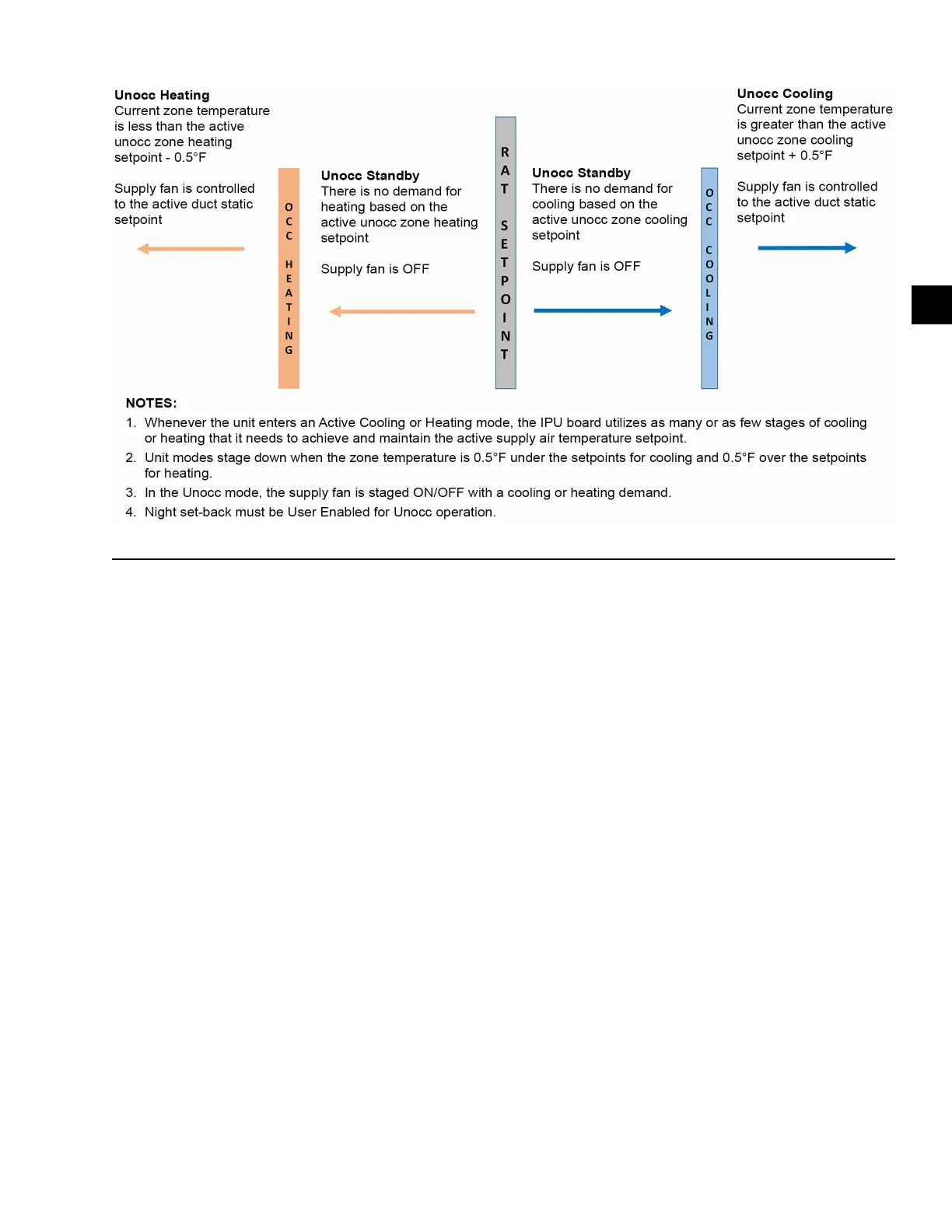

FIGURE 33 - VAV — UNOCCUPIED

COMPRESSORS: CONTROL AND OPERATION

Compressor Systems

• The Series 100 units have three completely inde-

pendent compressor systems. Each compressor

system has two compressors piped in a tandem

arrangement.

• Each system has a low pressure cutout (LPCO)

switch, a compressor safety chain, liquid line l-

ter driers, and two thermostatic expansion valves

(TXVs) (one each for the upper and lower evapo-

rator coils).

• Each compressor in a tandem arrangement can be

staged on independently of the other compressor.

This staging allows better control of the SAT and

keeps undercooling and overcooling to a mini-

mum under normal operating conditions.

Compressor Control

• The IPU board has internal logic and program-

ming to stage compressors ON/OFF to achieve

and maintain the active cooling SAT setpoint.

• Under normal operation, each compressor has a

3.5 minute guaranteed ON/OFF timer.

• Under normal operating conditions, there is a 3.5

minute Interstage Time Delay after any compressor

is started/stopped before starting/stopping another

compressor unless fast compressor start is User En-

abled.

Compressor Staging

• The Series 100 units have three sets of tandem

scroll compressors. This allows the unit to have

six stages of cooling.

• When the unit enters an Active Cooling mode, the

IPU board starts to stage compressors ON.

• The IPU board stages compressors ON/OFF to

achieve and maintain the active SAT setpoint.

• If a compressor system has experienced a Safety

Lockout, that circuit is removed from the compres-

sor staging circuit until the Safety Lockout clears.

• Compressor staging is also affected when only

one or two of the three systems have a low ambi-

ent package.

• See Table 27 on page 74 for compressor stag-

ing.

Loading...

Loading...