JOHNSON CONTROLS

110

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

SECTION 5 – SEQUENCE OF OPERATION

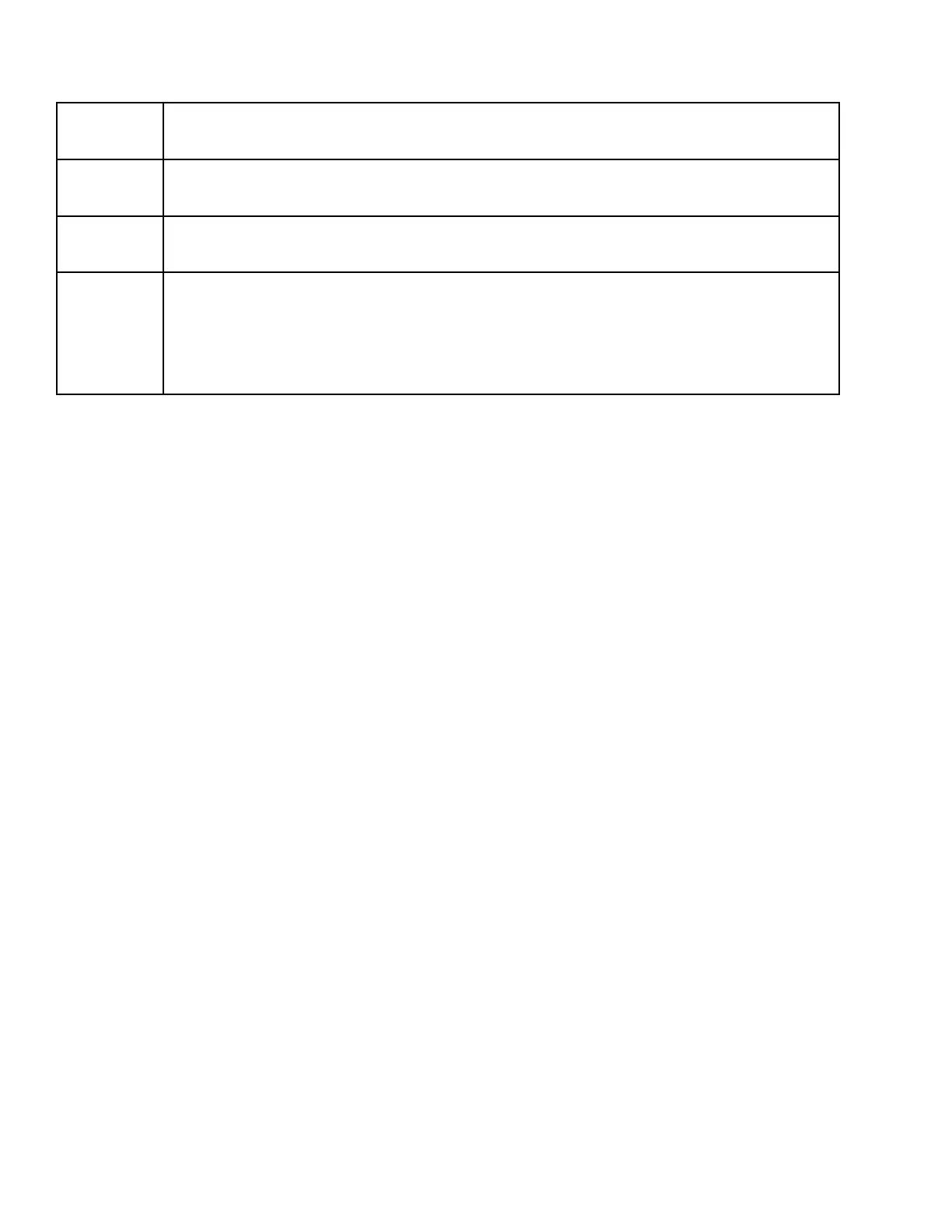

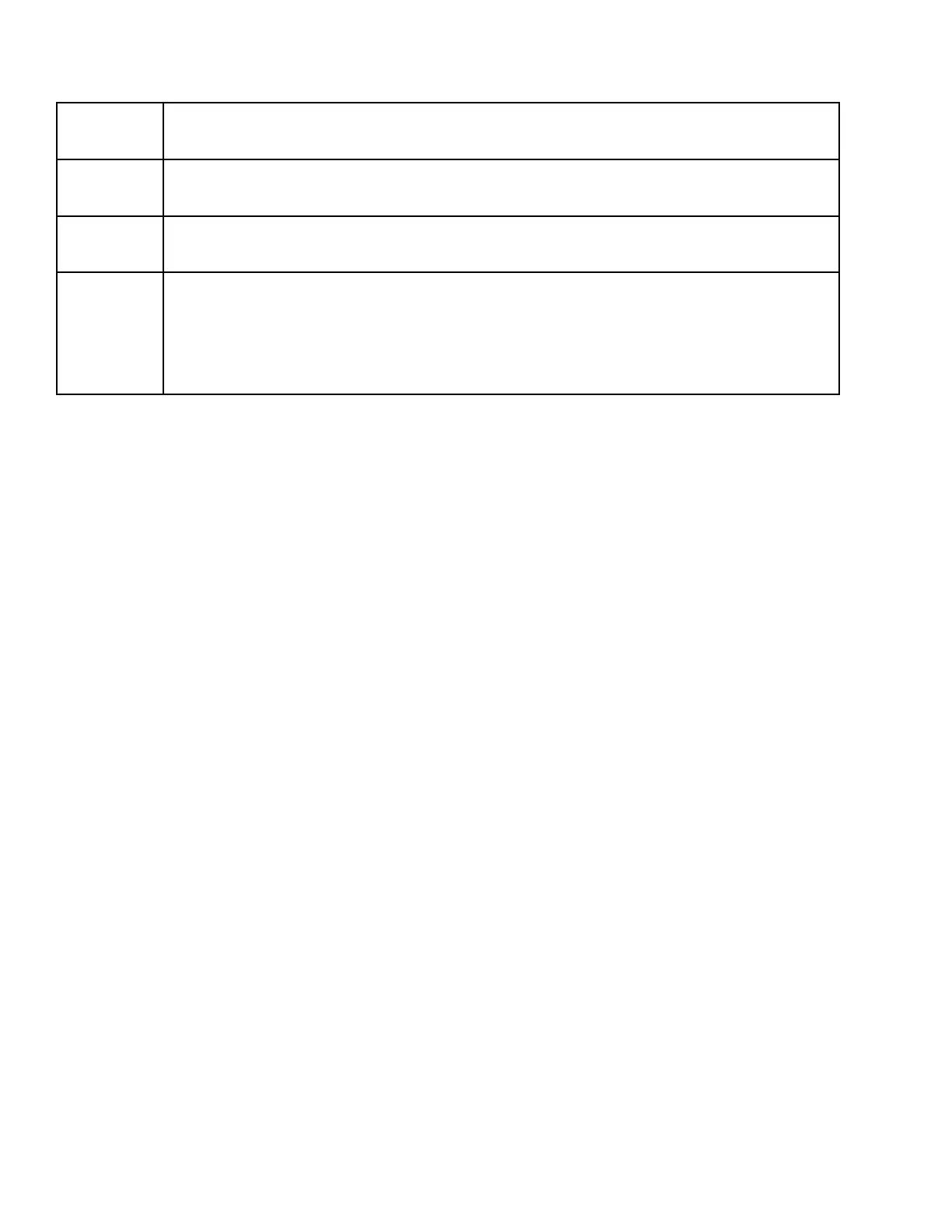

TABLE 40 - RETURN AIR BYPASS DAMPER

CURRENT %

The amount of air the IPU board calculates is bypassed because the mixed SAT is not increasing. The IPU

board utilizes the current RAT, the current EAT, and the mixed SAT to perform a calculation to arrive at the

current %.

ACTIVE

SETPOINT %

How much the return air the IPU board calculates is needed to bypass to warm the mixed SAT from its

current value to the mixed SAT setpoint. The IPU board utilizes the current RAT, current EAT, and current

mixed SAT to perform a calculation to arrive at the active setpoint %.

BYPASS

DAMPER

POSITION

This is the actual position of the bypass damper. The bypass damper should be able to drive between 0%

and 40%.

MAX BYPASS

This is the maximum amount of return air that the IPU board allows to bypass around the evaporator coil

through the FlexSys bypass damper.

The IPU board utilizes internal logic and calculations to determine how much of the return air is being

bypassed.

This is not the same as the actual bypass damper position. This is an adjustable setpoint with a range of

20–40%. We recommend leaving it at 40% for initial start-up and then adjusting down later if needed.

NOTE

It is likely that the above mentioned parameters—return air bypass current %, return air bypass active setpoint %, and bypass damper position

%—do not have matching values. This is normal; do not be alarmed.

Heating

• Occ and Unocc Heating operates the same as Occ

and Unocc Heating for a VAV congured unit.

• It is recommended to limit the SAT heating setpoint

between 80.0–90.0°F.

• Keeping the SAT heating setpoint between 80.0–

90 .0°F keeps the underoor slab from becoming

too warm and then radiating heat for an extended

period of time after heating operation has stopped.

Underfloor Temperature Control

• A FlexSys congured unit has two specialized se-

quences built in to help control the environment in

the underoor plenum:

• Dew Point Reset

• Active Slab Control

• Both of these sequences require an underoor slab

temperature sensor and an underoor humidity

sensor be installed.

• Both of these sensors are eld provided/installed.

Dew Point Reset

• This sequence changes the active EAT setpoint

from the EAT high setpoint to the EAT low

setpoint when the temperature of the underoor

air approaches its dewpoint.

• The unit must have an underoor slab temperature

sensor and an underoor humidity sensor installed

for this sequence to function.

• dew point reset must be set to User Enabled in the

PROGRAM-COOLING menu.

Sequence

• When the underfloor air dewpoint becomes

greater than the underfloor slab temperature

minus 2.0°F for 120 seconds, the IPU board

switches the active EAT setpoint from the

EAT high setpoint to the EAT low setpoint.

• The EAT low setpoint continues to be used as

the active EAT setpoint until the underfloor

air dewpoint becomes less than the under-

floor slab temperature minus 2.5°F.

Active Slab Control

• This sequence allows heat to be turned ON during

a transition from one occupancy state to another

when the underoor air temperature is higher than

the underoor slab temperature.

• The Series 100 unit must have a heating source

installed and set to User Enabled.

• Active Slab Control must be set to User Enabled

in the PROGRAM-COOLING menu.

• The unit must have an underoor slab temperature

sensor installed for this sequence to function.

Loading...

Loading...