JOHNSON CONTROLS

165

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

8

ANALOG INPUT OPERATION

This section describes the control operation of the 29

analog inputs. These inputs are used by the control to

monitor and respond to unit temperatures, pressures,

enthalpy, etc. The location of each of these connec-

tions on the IPU board is contained in Table 51 on page

132. Notice that the ID gives the jack connection des-

ignated as “J” and then the identifying number of the

connector, followed by a–and then the pin number of

the connector. For example, the SUPPLY AIR TEM-

PERATURE analog input would be found at J1-1. This

is connector J1–Pin 1. As the IPU board board is po-

sitioned in the control box the top row of the J series

connectors is the input, the middle row is the common,

and the bottom row is the 5VDC input to the sensor.

Also the pin in the right hand top corner is pin 1.

Temperature Sensors

The temperature sensors are all 10K Type III Thermis-

tors. The relationship between the temperature and the

voltage output and resistance is contained in Table 55

on page 165. The following analog input are of this

type: Supply Air Temperature, Heat Entering Temp,

Outside Air Temp, Return Air Temp, Suction Temp #1,

Suction Temp #2, Suction Temp #3, and Zone Temp.

Duct Pressure Transducer

The Duct Pressure Transducer is locatedin the return air

section of the unit. The purpose of the transducer is to

sense and convert the static pressure in the supply-side

of the duct to a 0 to 5VDC voltage. The DC voltage is

sent to the IPU board and compared against the duct

static press active setpoint. The transducer is factory

wired, but pneumatic tubing must be field supplied and

installed (refer to SECTION 2 – INSTALLATION). The

duct static pressure transducer measures differential

pressure between the pressure in the duct and atmo-

spheric pressure. When verifying transducer operation,

the technician must insert a tee in the pneumatic tubing

and connect a manometer to the tee to verify the pres-

sure being applied to the transducer. Once this pressure

is known, a comparison can be made of the duct pres-

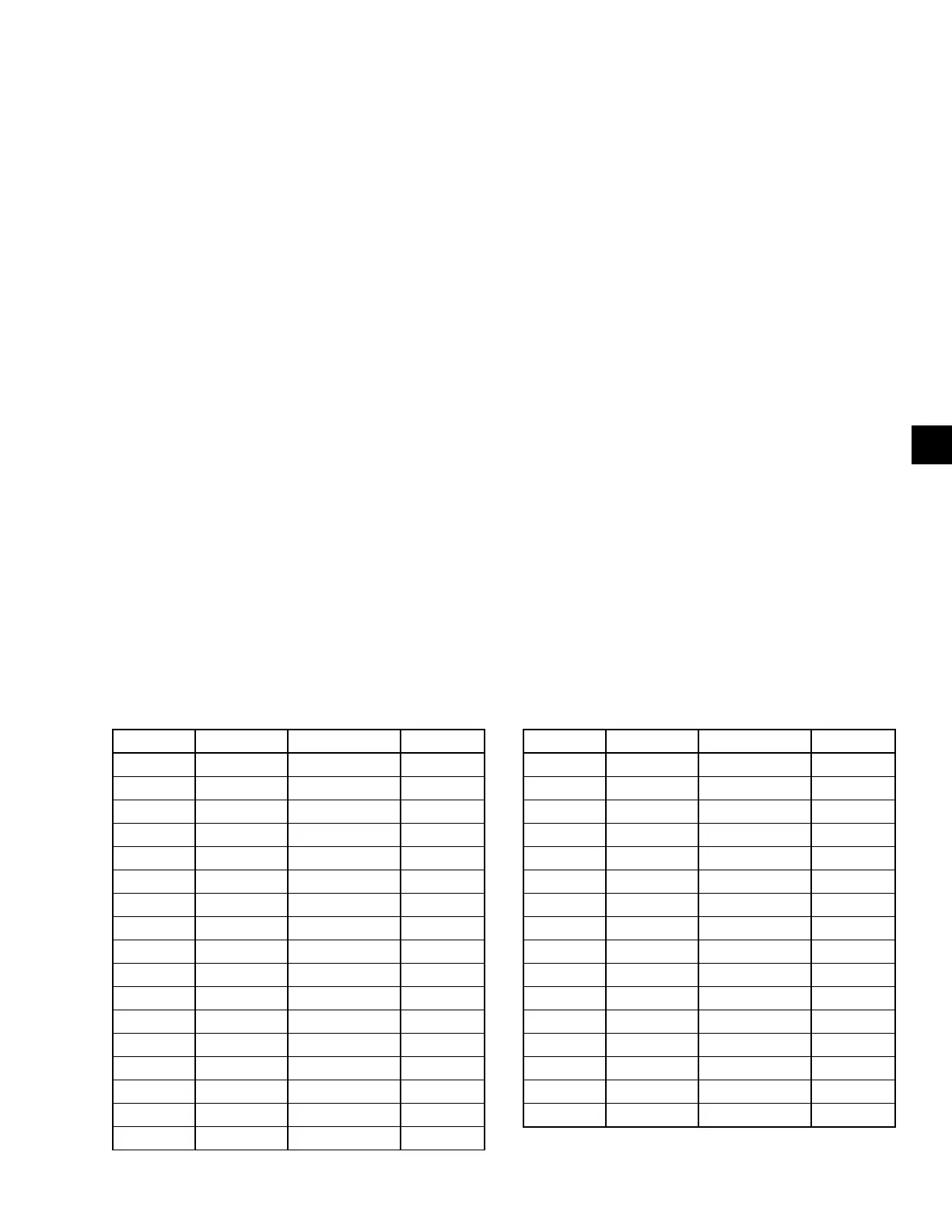

sure vs. output VDC from the transducer. Table 56 on

page 166 shows the relationship between the pressure

applied to the duct pressure transducer and the output

voltage. The output is linear between 0" W.C. and the

SPAN. The “DUCT PRESS TRANSDUCER SPAN”

can be set to 1.25, 2.5 or 5" W.C.

SECTION 8 – SERVICE

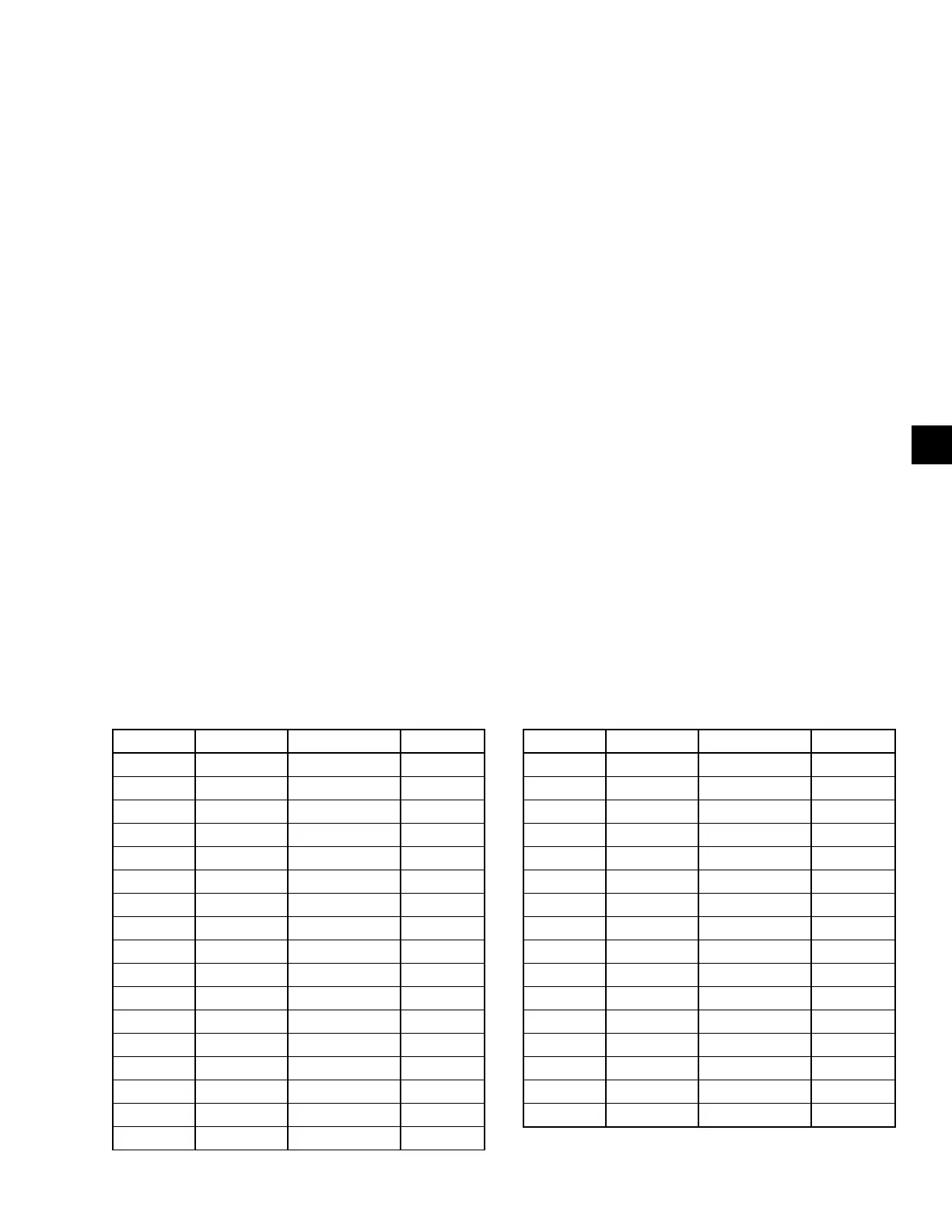

TABLE 55 - TEMPERATURE SENSOR RESISTANCE

°F VOLTAGE RESISTANCE °C

-25 0.49 139,639 -30.6

-20 0.53 127,453 -28.9

-15 0.60 109,624 -26.1

-10 0.69 94,519 -23.34

-5 0.78 81,665 -20.55

0.0 0.88 70,750 -17.78

5 0.98 61,418 -15.00

10 1.10 53,426 -12.22

15 1.22 46,582 -9.44

20 1.35 40,703 -6.67

25 1.48 35,639 -3.89

30 1.62 31,269 -1.11

35 1.77 27,490 1.67

40 1.91 24,219 4.44

45 2.06 21,377 7.22

50 2.21 18,900 10.00

55 2.36 16,744 12.78

°F VOLTAGE RESISTANCE °C

60 2.51 14,681 15.56

65 2.66 13,216 18.33

70 2.80 11,771 21.11

75 2.94 10,502 23.89

80 3.08 9,388 26.67

85 3.21 8,404 29.45

90 3.33 7,537 32.22

95 3.45 6,770 35.0

100 3.56 6,090 37.78

105 3.66 5,487 40.56

110 3.76 4,951 43.34

115 3.85 4,475 46.11

120 3.94 4,050 48.89

125 4.02 3,671 51.66

130 4.09 3,332 54.44

135 4.16 3,029 57.22

Loading...

Loading...