JOHNSON CONTROLS

163

SECTION 7 – PARAMETER DESCRIPTIONS AND OPTIONS

FORM 100.50-NOM12

ISSUE DATE: 04/02/2019

7

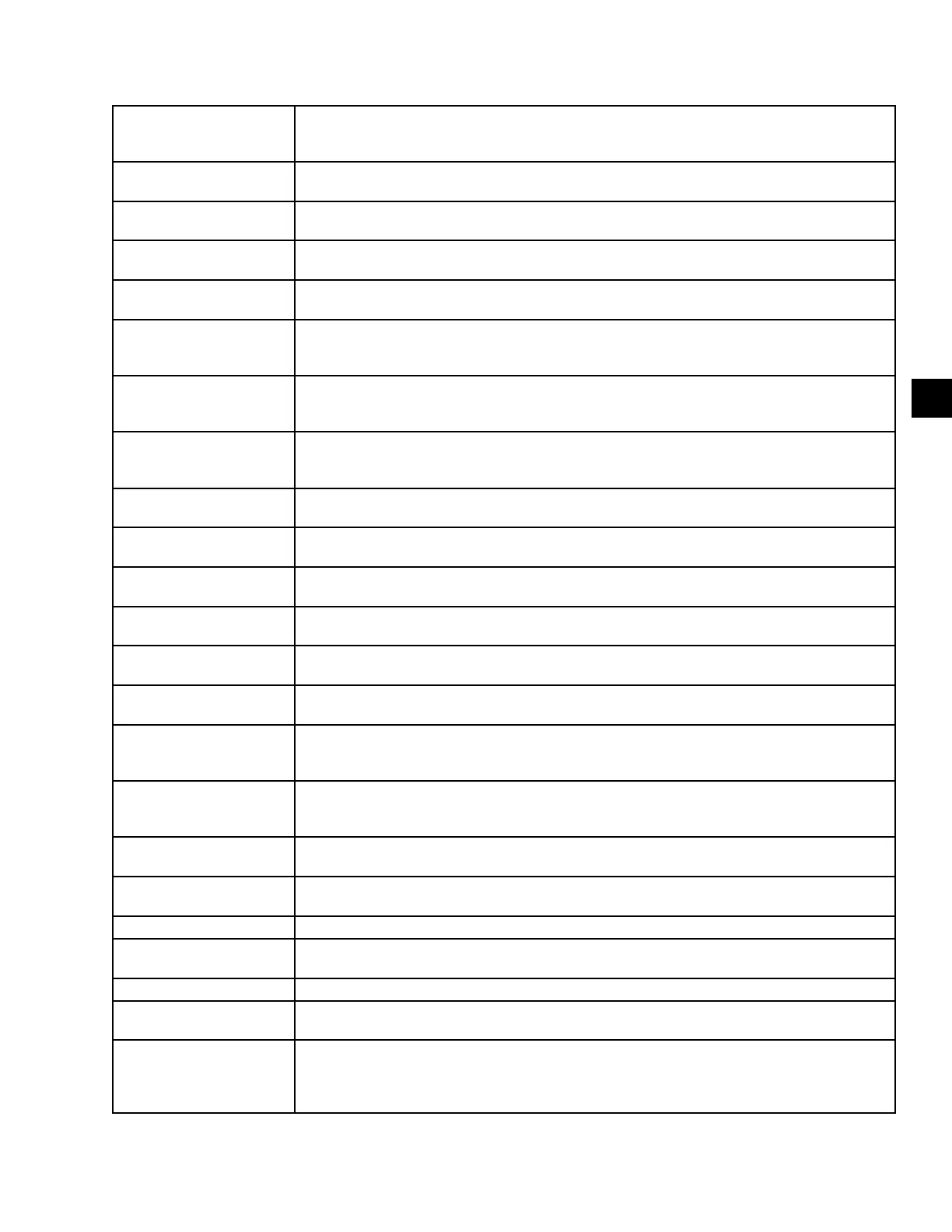

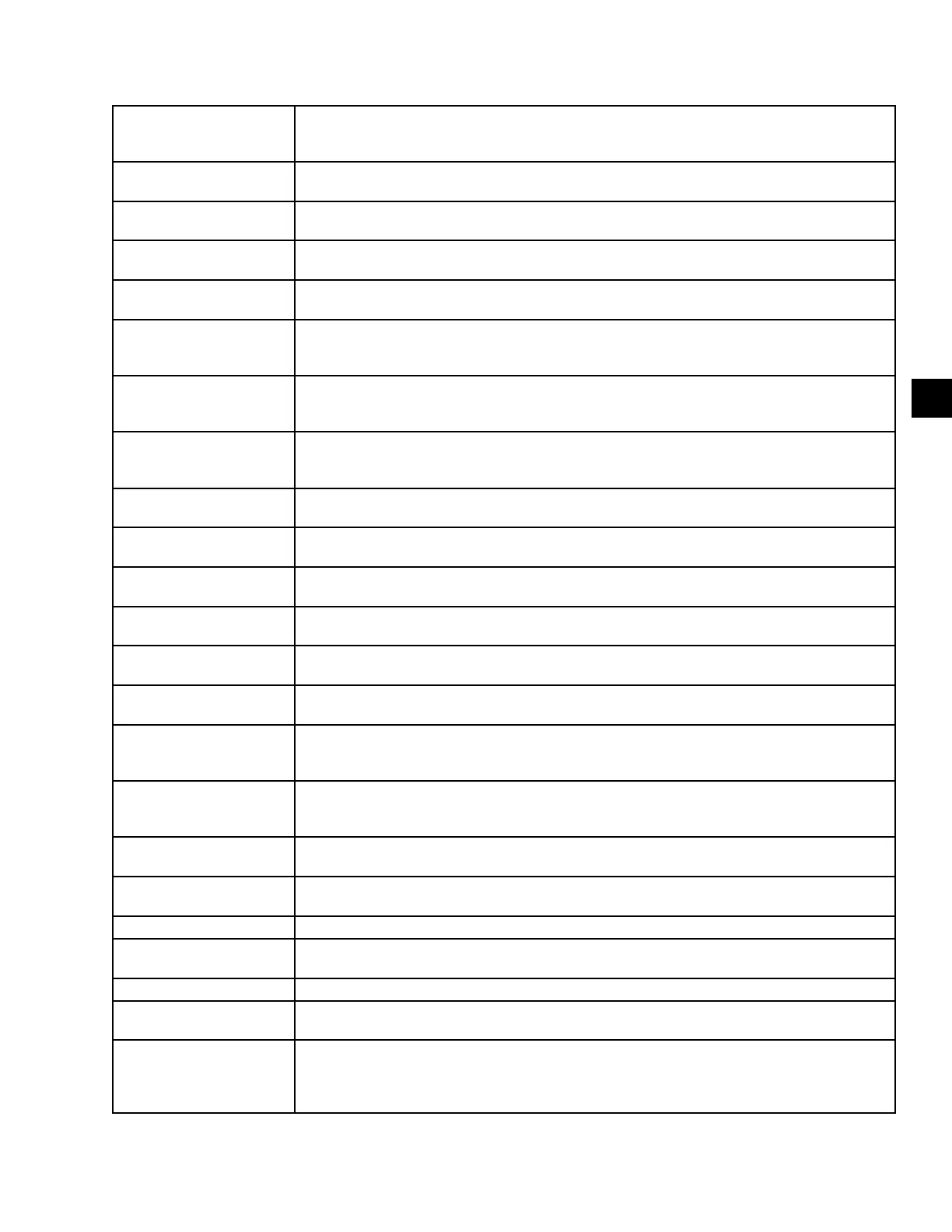

SAT RESET METHOD

This parameter is programmed through the OPTIONS key and identies the Supply Air

Temperature reset method being used on a Variable Air Volume Unit. The choices are

Hardwired, Outside Air, Return Air, or Supply Fan Speed.

SAT HIGH SETPOINT

This parameter is programmed through the SETPOINTS key. This establishes the maximum

Active Supply Air Temperature to be used in a Variable Air Volume Unit.

SAT LOW SETPOINT

This parameter is programmed through the SETPOINTS key. This establishes the minimum

Active Supply Air Temperature to be used in a Variable Air Volume Unit.

SENSOR / MISC STATUS

This is the current status of the Sensors. The display will show Normal, Warning, Safety Trip,

Safety Fault, or Safety Lockout.

SINGLE ZONE MINIMUM

VAV SPEED

This parameter provides the minimum speed of the Supple Fan during SZVAV operation.

SMOKE PURGE SEQ 1

This parameter is programmed through the OPTIONS key. This allows the user to select

which of the three smoke purge sequences to use a sequence 1, Purge, Pressurization, or

Evacuation. Smoke Purge Sequence 1 is energized through a Binary input to the IPU board.

SMOKE PURGE SEQ 2

This parameter is programmed through the OPTIONS key. This allows the user to select

which of the three smoke purge sequences to use a sequence 2, Purge, Pressurization, or

Evacuation. Smoke Purge Sequence 2 is energized through a Binary input to the IPU board.

SMOKE PURGE SEQ 3

This parameter is programmed through the OPTIONS key. This allows the user to select

which of the three smoke purge sequences to use a sequence 3, Purge, Pressurization, or

Evacuation. Smoke Purge Sequence 3 is energized through a Binary input to the IPU board.

1ST STAGE COOLING

SETPOINT

This parameter is programmed through the SETPOINTS key. This value is used in a Constant

Volumn unit as the Active SAT Setpoint for 1st Stage cooling operation.

1ST STAGE HEATING

SETPOINT

This parameter is programmed through the SETPOINTS key. This value is used in a Constant

Volumn unit as the Active SAT Setpoint for 1st Stage heating operation.

2ND STAGE 2 COOLING

SETPOINT

This parameter is programmed through the SETPOINTS key. This value is used in a Constant

Volumn unit as the Active SAT Setpoint for 2nd Stage cooling operation.

2ND STAGE 2 HEATING

SETPOINT

This parameter is programmed through the SETPOINTS key. This value is used in a Constant

Volumn unit as the Active SAT Setpoint for 2nd Stage heating operation.

STAGED HEAT STATUS

STGS ON

This identies the number of stages of gas or electric heat that the IPU board has energized.

STAGED HEAT STATUS

STGS AVAIL

This identies the number of stages of gas or electric heat that are available.

SUCTION TEMP

This is the temperature of the suction line leaving the evaporator coil and is shown for each

system. This value is monitored and used to prevent liquid refrigerant from being returned to

the compressor.

SUP AIR TEMPERING

This parameter is programmed through the PROGRAM key. This parameter is used to allow

the heat to operate when the unit is in the Occupied Standby mode to temper the ventilation air

entering the space. The choices are USER ENABLED or USER DISABLED.

SUPPLY AIR TEMP

ACTIVE SP

This is the Supply Air Temperature the IPU board is trying to maintain.

SUPPLY AIR TEMP

CURRENT

This is the current Supply Air Temperature supplied by the unit.

SUPPLY FAN OUTPUT This is the Binary output from the IPU board to the Supply Fan control system.

SUPPLY FAN OUTPUT

PROOF

This is a Binary input into the IPU board that identies the Supply Fan is functioning.

SUPPLY FAN VFD SPEED This indicates the output, in percent, to the Supply Fan VFD.

SUPPLY SYS STATUS

This is the active status of the Supply System, display will show Normal- Active; Normal-

Inactive; Safety Trip, Safety Fault, or Safety Lockout.

SYSTEM UNLOADING

PRESSURE

This parameter is programmed through the SETPOINTS key. If two compressors of the system

are operative and the discharge pressure is equal to or greater than this value the IPU board

will turn off one of the compressors. This feature is only operative when a discharge pressure

transducer is installed in the compressor system.

TABLE 54 – DEFINITIONS (CONT'D)

Loading...

Loading...