30/ENGINE - WORK ON INDIVIDUAL PARTS 104

200476-10

– Piston size is marked on the piston head.

20.14Checking the piston ring end gap

200477-10

– Remove the piston ring from the piston.

– Place the piston ring in the cylinder and align it with the piston.

Guideline

Under the upper edge of the cylinder 10 mm (0.39 in)

– Measure the end gap with special tool .

Guideline

Piston ring end gap ≤ 0.5 mm (≤ 0.02 in)

Feeler gauge (59029041100) ( p. 196)

» If the end gap is more than the specified value:

– Check/measure the cylinder. ( p. 102)

» If the cylinder wear is within the tolerance range:

– Change the piston ring.

– Mount the piston ring with the marking facing toward the piston head.

20.15Checking the piston/cylinder mounting clearance

– Check/measure the cylinder. ( p. 102)

– Check/measure the piston. ( p. 103)

– The smallest piston/cylinder mounting clearance is the result of the smallest cylinder bore diameter minus the largest piston diam-

eter. The largest piston/cylinder mounting clearance is the result of the largest cylinder bore diameter minus the smallest piston

diameter.

Guideline

Piston/cylinder - mounting clearance

New condition 0.015… 0.057 mm (0.00059… 0.00224 in)

Wear limit 0.150 mm (0.00591 in)

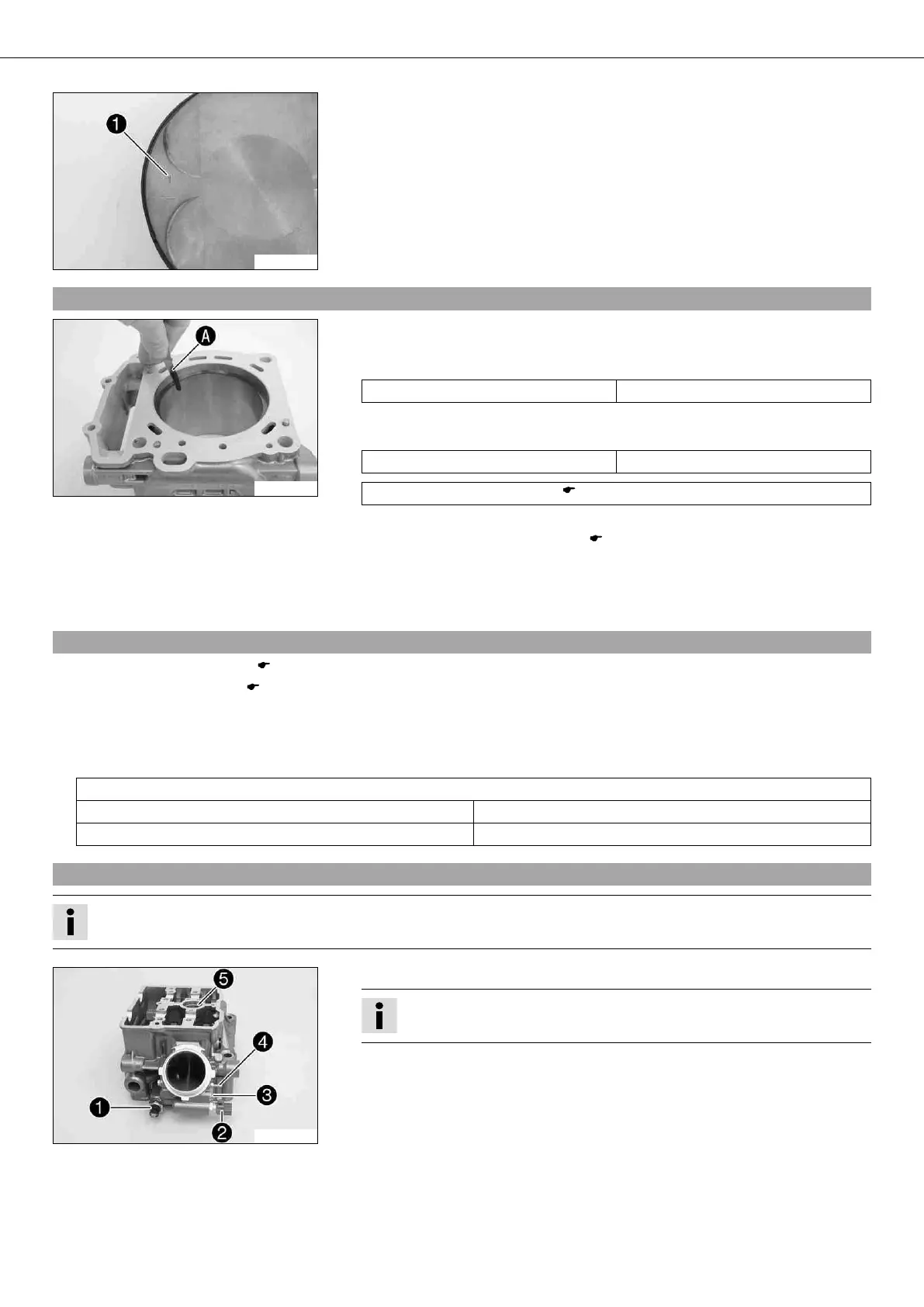

20.16Work on the cylinder head

Info

The following operations apply to both cylinder heads.

200466-10

– Remove oil pressure switch .

Info

This only applies to the front cylinder head!

– Remove coolant temperature sensor .

– Remove screw .

– Remove vacuum connection .

– Remove O-rings .

Loading...

Loading...