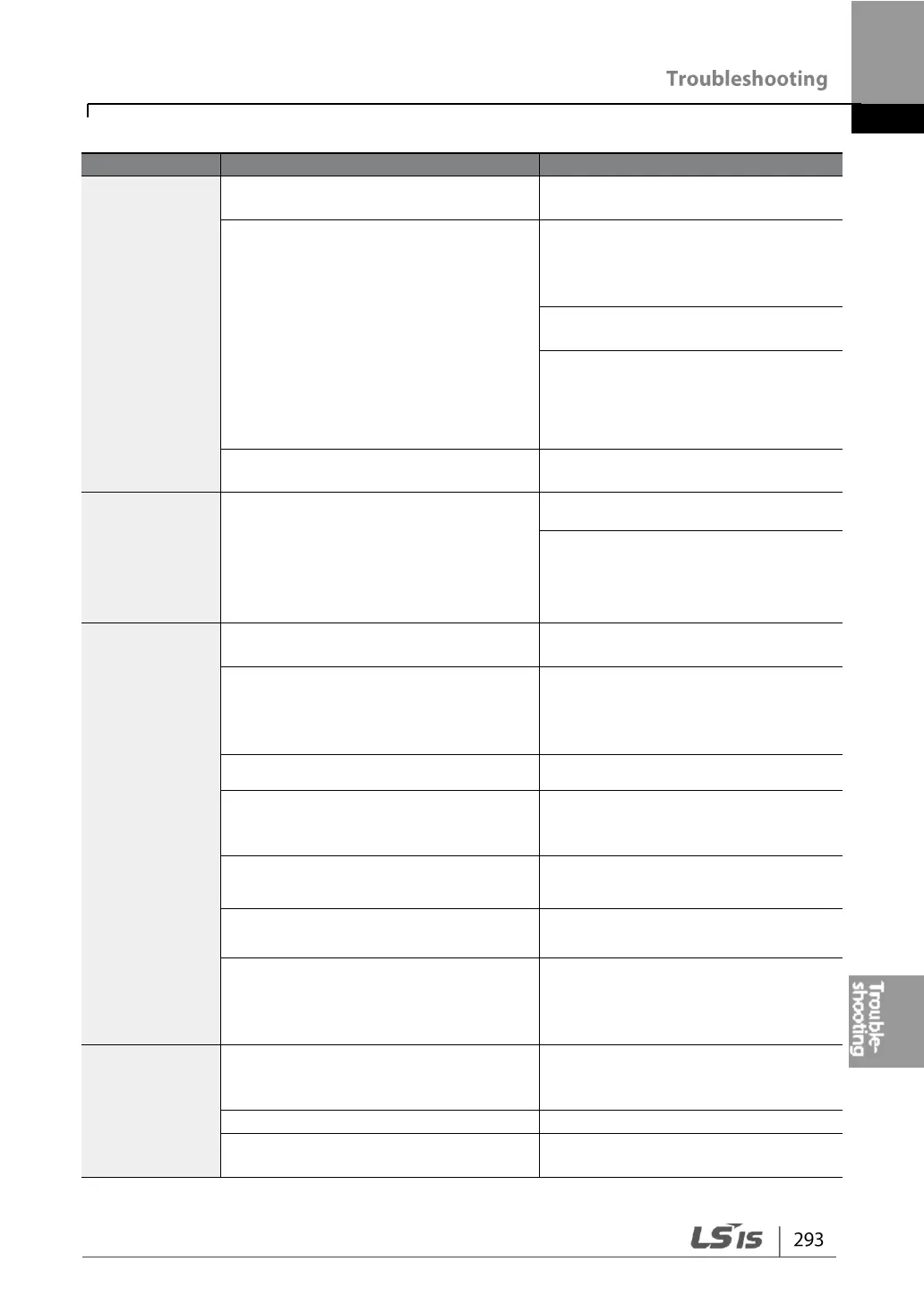

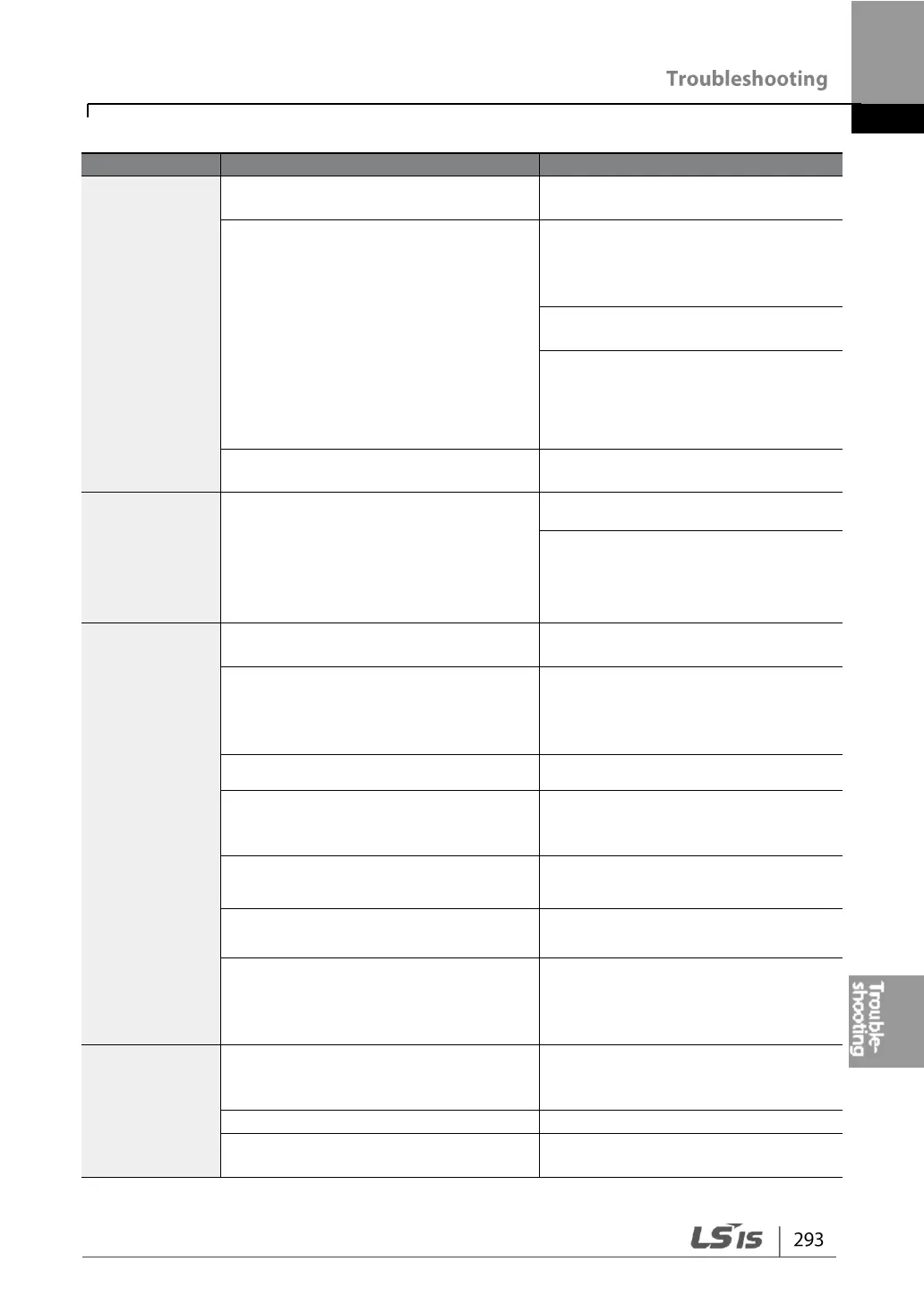

The ambient temperature of the

motor is too high.

Lower the ambient temperature of

the motor.

The phase-to-phase voltage of the

motor is insufficient.

Use a motor that can withstand

phase-to-phase voltages surges

greater than the maximum surge

voltage.

Only use motors suitable for

applications with inverters.

Connect the AC reactor to the

inverter output (set the carrier

frequency to 2 kHz).

The motor fan has stopped or the

fan is obstructed with debris.

Check the motor fan and remove

any foreign objects.

The motor

stops during

acceleration or

when

connected to

load.

Replace the motor and the inverter

with models with appropriate

capacity for the load.

The motor

does not

accelerate.

/The

acceleration

time is too

long.

The frequency command value is

low.

Set an appropriate value.

Reduce the load. Increase the

acceleration time.

Check the mechanical brake

status.

The acceleration time is too long.

Change the acceleration time.

The combined values of the motor

properties and the inverter

parameter are incorrect.

Change the motor related

parameters.

The stall prevention level during

acceleration is low.

Change the stall prevention level.

The stall prevention level during

operation is low.

Change the stall prevention level.

Starting torque is insufficient.

Change to vector control operation

mode. If the fault remains, replace

the inverter with a model with

increased capacity.

Motor speed

varies during

operation.

There is a high variance in load.

Replace the motor and inverter

with models that have increased

capacity.

The input voltage varies.

Reduce input voltage variation.

Motor speed variations occur at a

specific frequency.

Adjust the output frequency to

avoid a resonance area.

Loading...

Loading...