214713 143 Revision A

7.13 Checking Roll Tension

Roll tension is indicated by the exposed thread on the roll tension adjuster bolt.

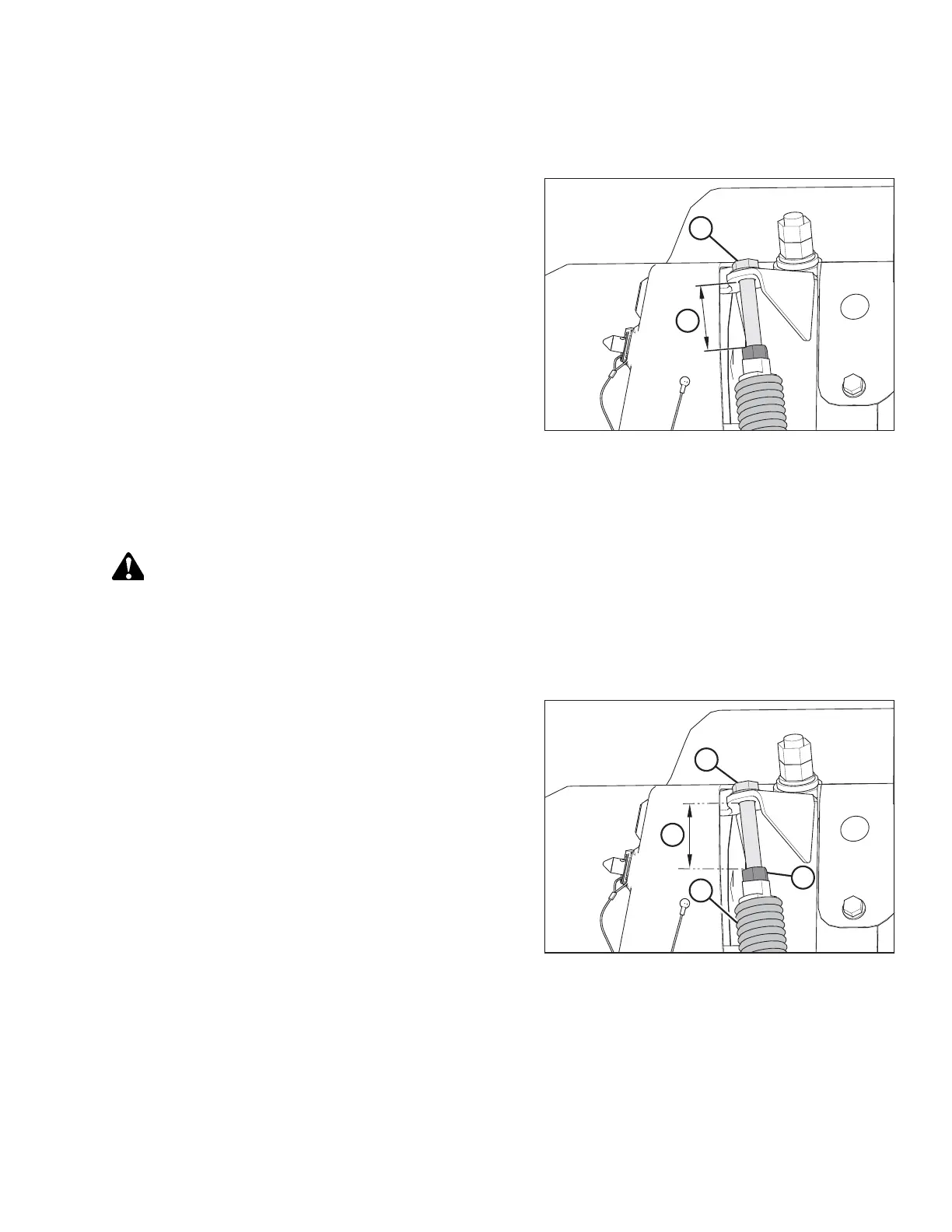

Figure 7.24: Roll Tension Adjuster

1. Measure the amount of exposed thread on the roll

tension adjuster bolt (A) at each end of the conditioner.

Measurement (B) should be 12–15 mm (1/2–9/16 in.)

for both polyurethane and steel roll conditioners.

2. If the tension requires adjusting, refer to 7.13.1

Adjusting Roll Tension, page 143.

7.13.1 Adjusting Roll Tension

To adjust roll tension, follow these steps:

DANGER

To avoid bodily injury or death from unexpected startup of the machine, always stop the engine and

remove the key from the ignition before leaving the operator’s seat for any reason.

1. Lower the disc mower to the ground.

2. Stop the engine, and remove the key from the ignition.

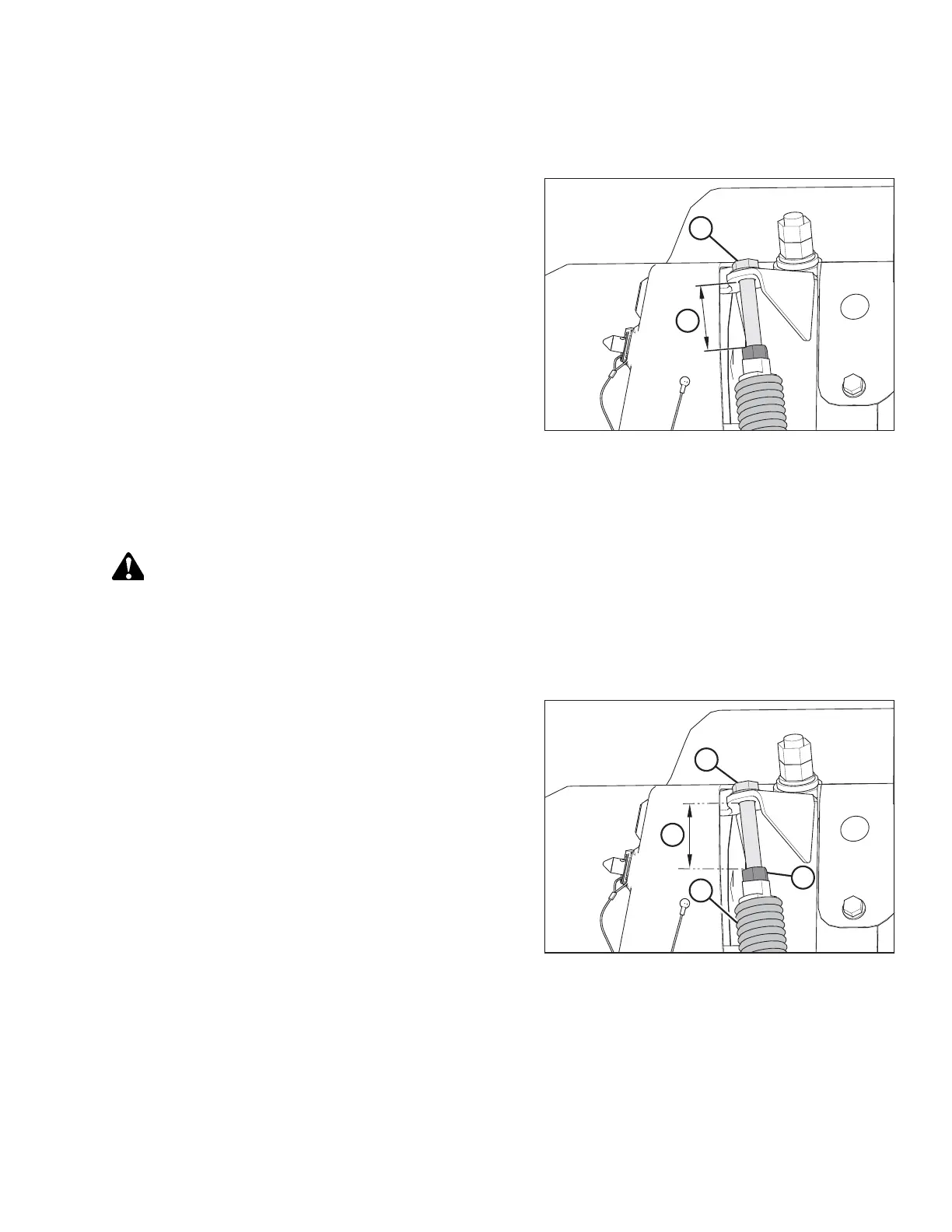

Figure 7.25: Left Side Shown – Right Side

Opposite

3. Loosen jam nut (A) on both sides of conditioner.

4. Turn the spring drawbolt (B) clockwise to tighten

spring (C) and INCREASE roll tension.

5. Turn the spring drawbolt (B) counterclockwise to loosen

spring (C) and DECREASE roll tension.

6. Measure the amount of exposed thread on spring

drawbolt (B) at each end of the conditioner.

Measurement (D) should be 12–15 mm (1/2–9/16 in.)

for both polyurethane and steel roll conditioners.

IMPORTANT:

Turn each bolt equally. Each turn of the bolt changes

the roll tension by approximately 32 N (7.2 lbf).

7. Tighten jam nuts (A) on each end of the conditioner.

PERFORMING PREDELIVERY CHECKS

Loading...

Loading...