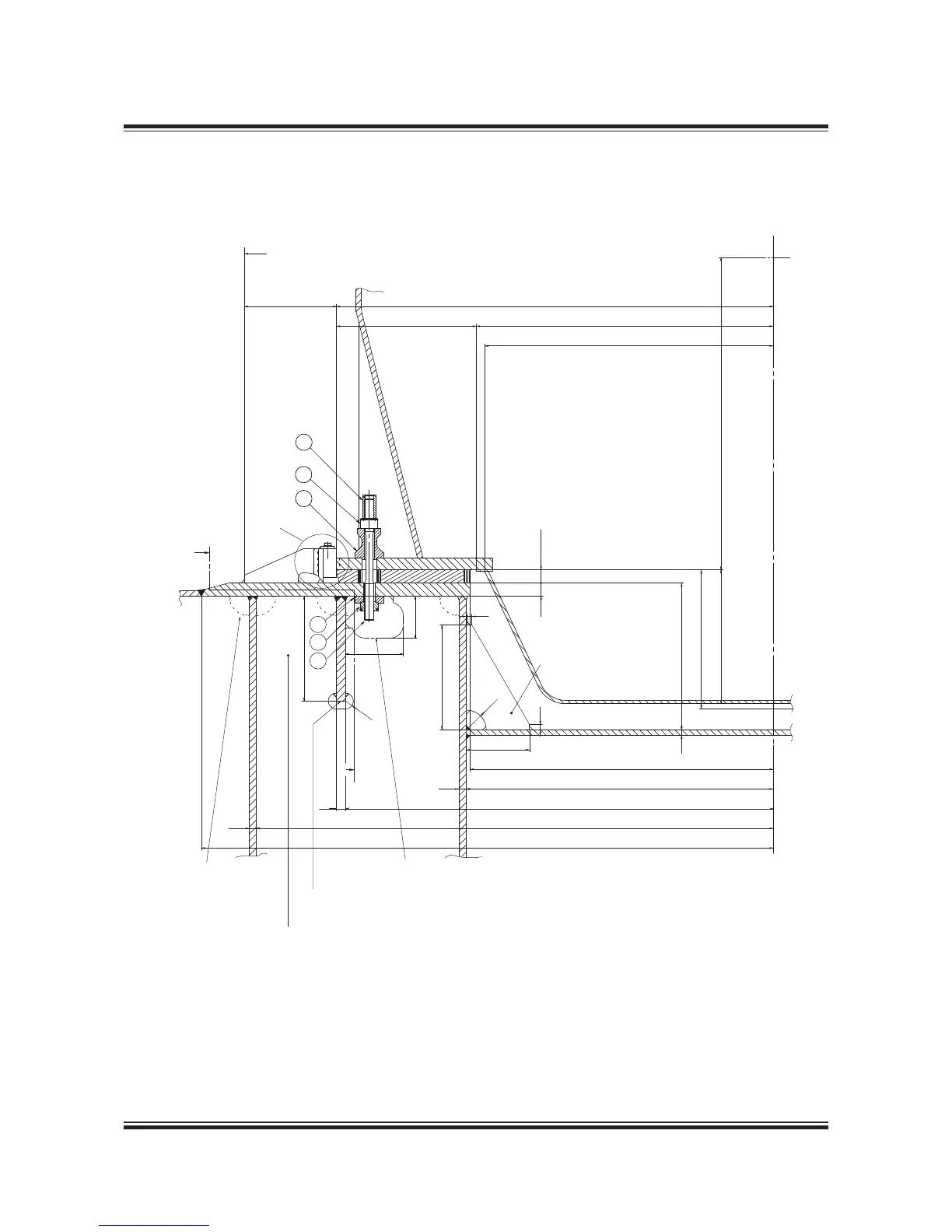

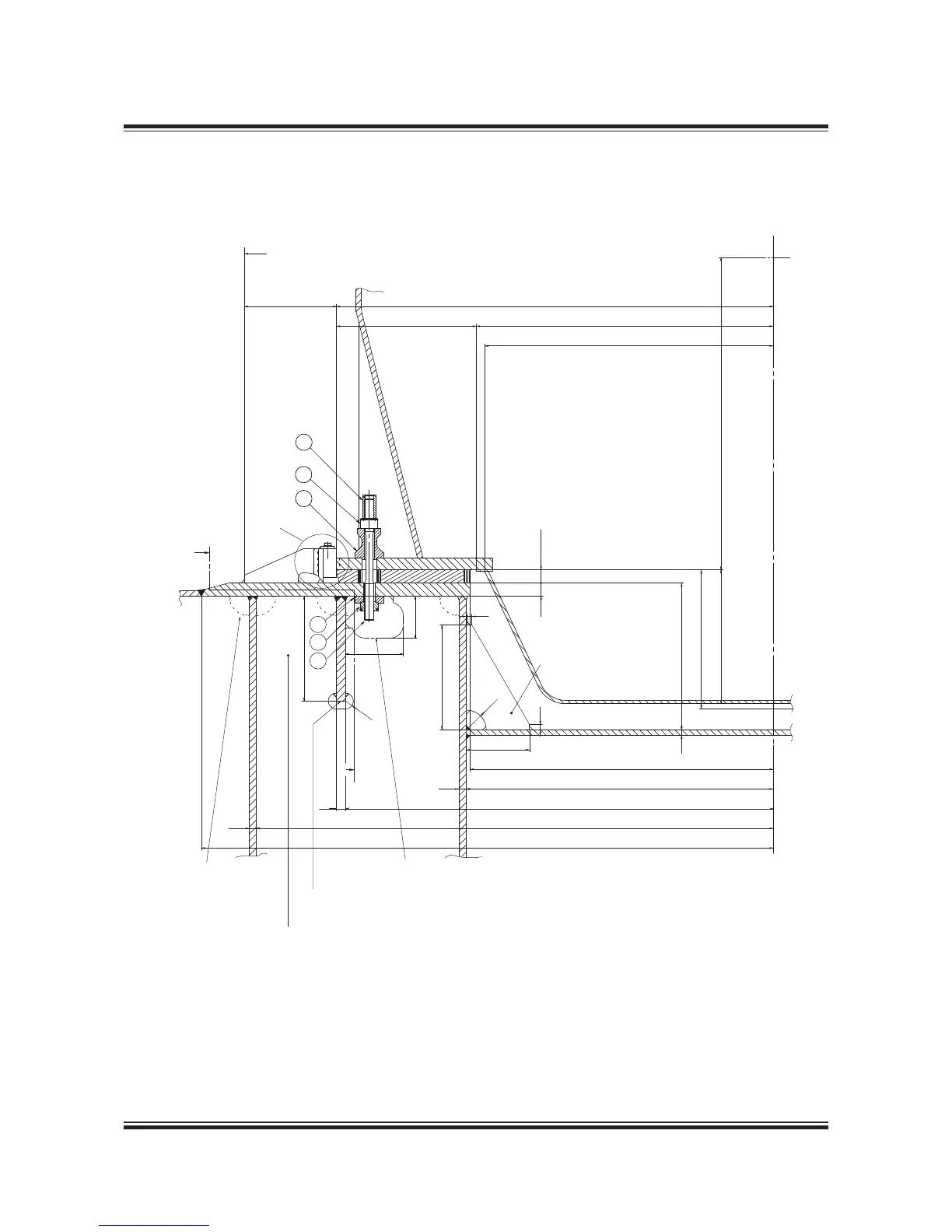

Fig. 5.12.02a : Profile of engine seating

Engine Seating Profile

Holding down bolts, option: 4 82 602 include:

1. Protecting cap

2. Spherical nut

3. Spherical washer

079 40 88-6.2.0a

4. Distance pipe

5. Round nut

6. Holding down bolt

Section A-A

160

220

Centreline engine

400

R30

1,132

1,100

1,665

533

350

+35

50 -25

50

1,190 to centreline crankshaft

510

529

56020

28

1,630

1,970

2,18 0

1,155

1,170

36

28

This space to be kept free from pipes etc. along both sides

of the engine in order to facilitate the overhaul work on

holding down bolts, supporting chocks and side chocks.

Thickness of floorplates

between main engine girders 22mm.

Continuous girder to extend with full dimensions

at least to ship's frame forward of engine and at

least to ship's frame aft of the aft end of end chock.

Corners of

floorplates

to be cut to

enable proper

welding of

girders. e.g.

as shown.

Slots to be cut in vertical floorplates

to clear nuts when necessary.

400

20

R75

240

20

If required by classification

society, apply this bracket.

Thickness of bracket is the

same as thickness of floorplates

D1

3

2

6

1

5

4

B

B

Loading...

Loading...