The letters refer to list of ‘Counterflanges’

Cylinder Lubricating Oil System

The cost of the cylinder lubricating oil is one of the

largest contributions to total operating costs, next

to the fuel oil cost. Another aspect is that the lu-

brication rate has a great influence on the cylinder

condition, and thus on the overhauling schedules

and maintenance costs.

It is therefore of the utmost importance that the

cylinder lubricating oil system as well as its opera-

tion is optimised.

Cylinder oils

In short, MAN Diesel and Turbo recommends the

use of cylinder oils with the following main proper-

ties:

• SAE 50 viscosity grade

• high detergency

• BN 100 for high-sulphur fuel

• BN 40 for low-sulphur fuel.

A BN 100 cylinder oil is to be used as the default

choice of oil and it may be used on all fuel types.

However, in case of the engine running on fuel

with sulphur content lower than 1.5% for more

than 2 weeks, we recommend to change to a

lower BN cylinder oil such as a BN 40.

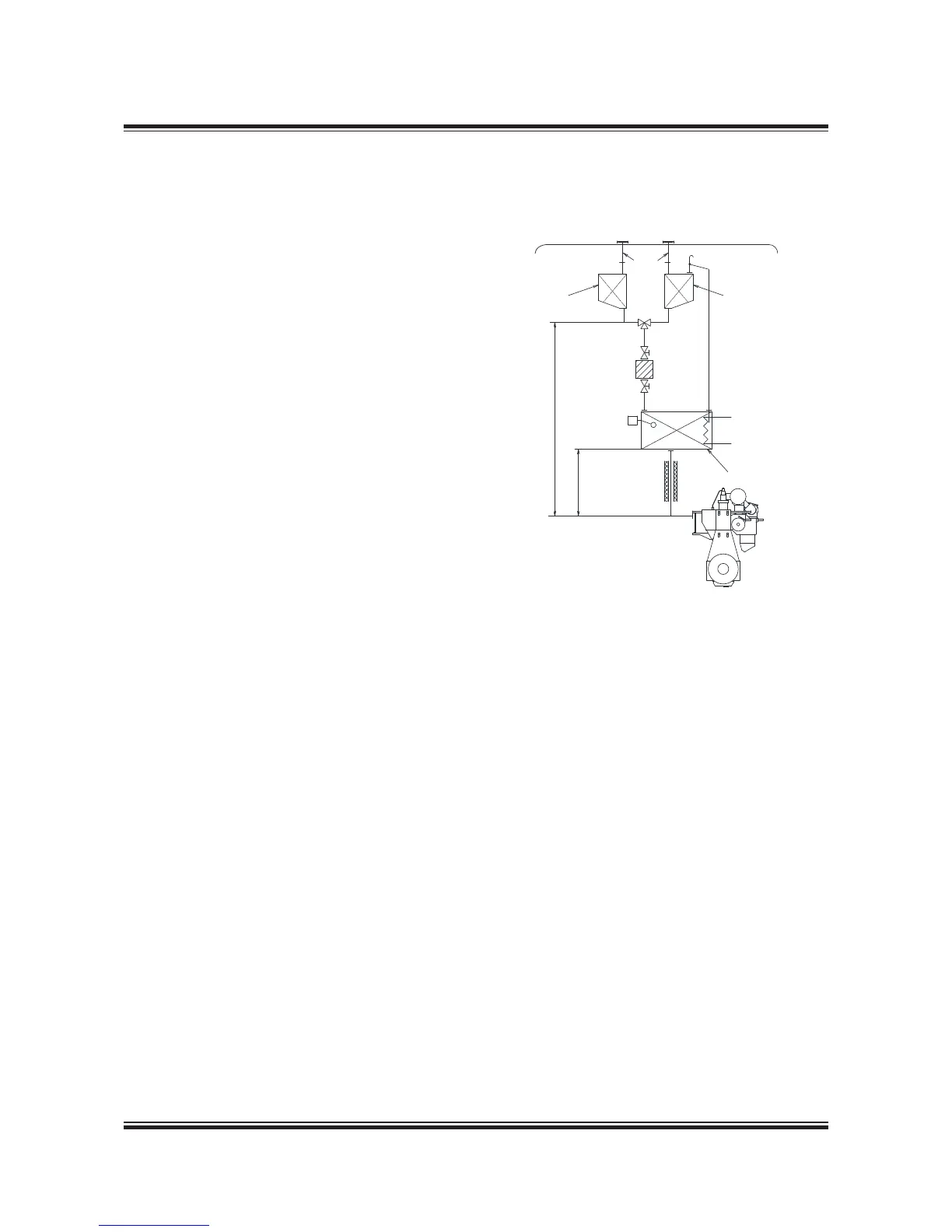

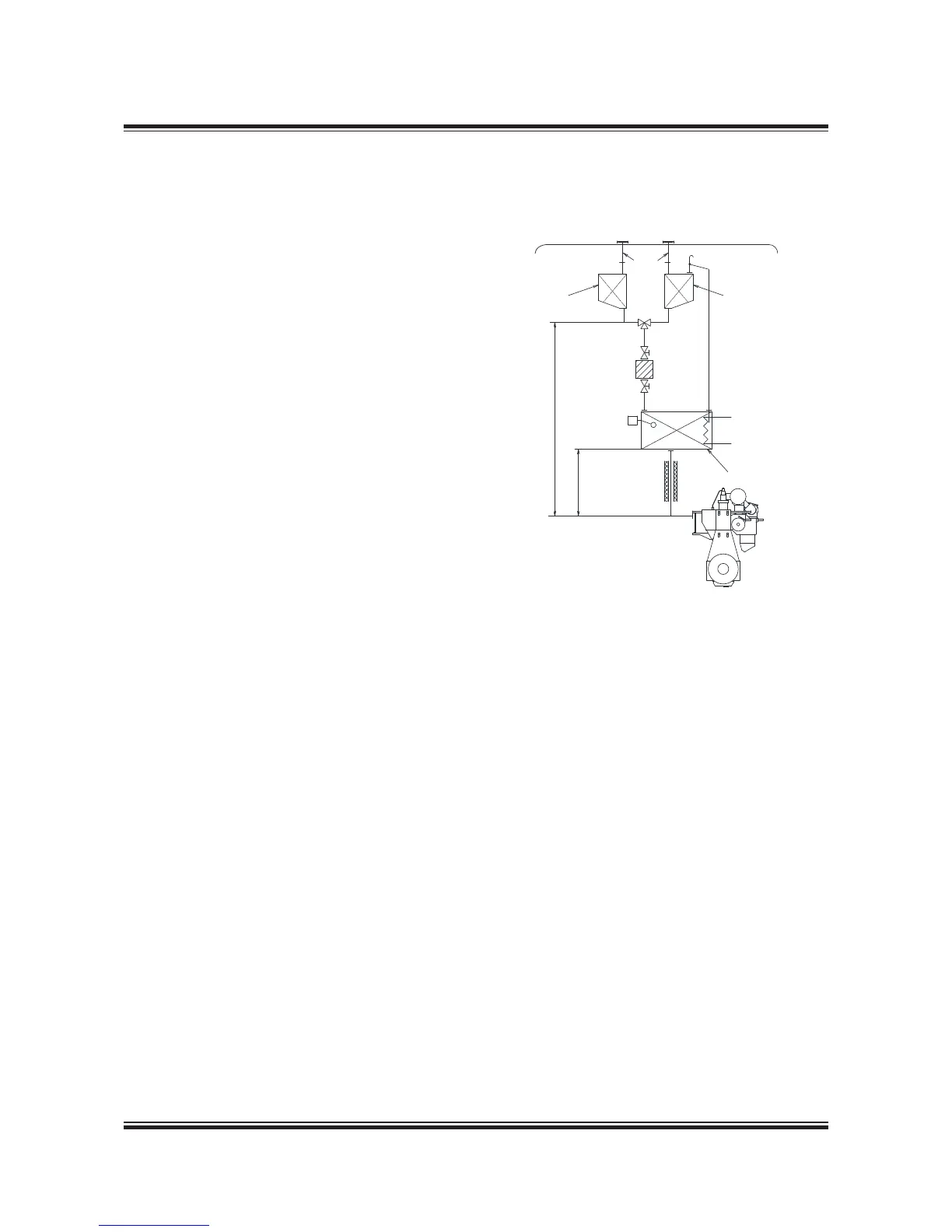

Two-tank cylinder oil supply system

Fig. 9.01.01 shows a cylinder oil supply system

with separate tanks for cylinder oils with high and

low BN.

Cylinder oil feed rate (dosage)

Adjustment of the cylinder oil dosage to the sul-

phur content in the fuel being burnt is further ex-

plained in Section 9.02.

Further information about cylinder lubrication on

different fuel types is available in our publication:

Operation on Low-Sulphur Fuels

The publication is available at www.marine.man.

eu → ’Two-Stroke’ → ’Technical Papers’.

Loading...

Loading...