Power Supply for Engine Control System

The Engine Control System requires two separate

power supplies with battery backup, power supply

A and B.

The ME-ECS power supplies must be separated

from other DC systems, i.e. only ME-ECS compo-

nents must be connected to the supplies.

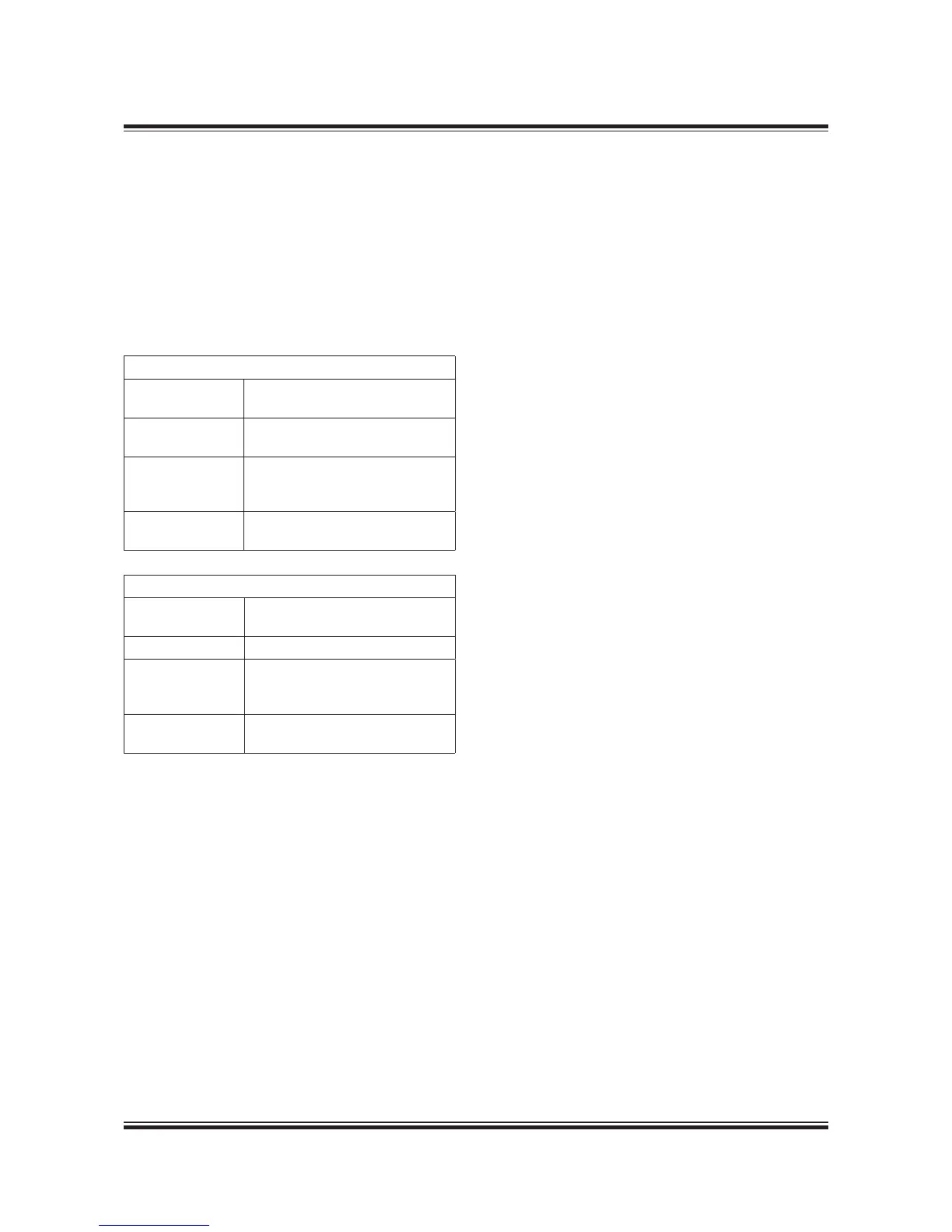

Power supply A

System IT (Floating), DC system w.

individually isolated outputs

Voltage Input 100-240V AC, 45-65 Hz,

output 24V DC

Protection Input over current, output over

current, output high/low

voltage

Alarms as potential

free contacts

AC power, UPS battery mode,

Batteries not available (fuse fail)

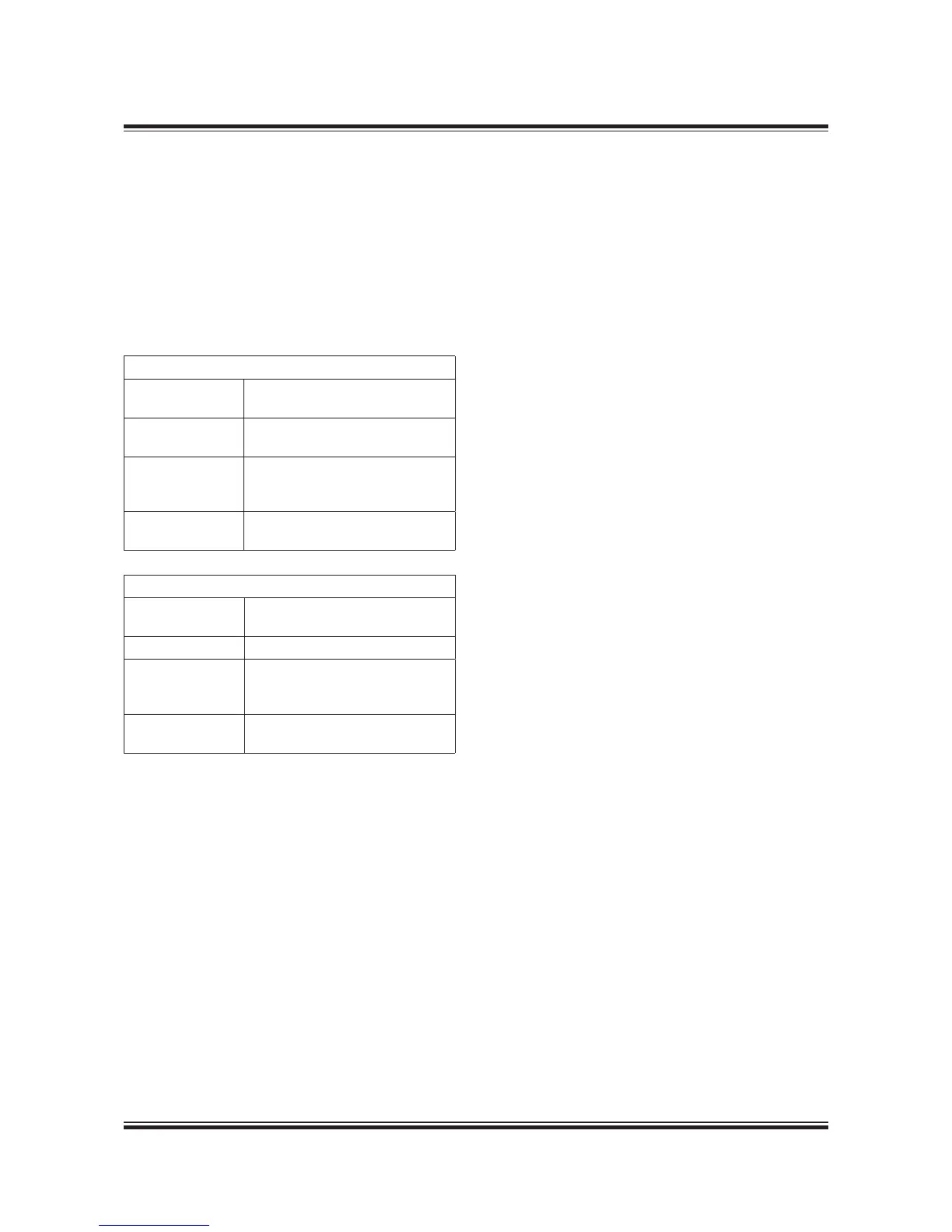

Power supply B

System IT (Floating), DC system w.

individually isolated outputs

Voltage Input 110-240 VAC, output 24V DC

Protection Input over current, output over

current, output high/low

voltage

Alarms as potential

free contacts

AC power, UPS battery mode,

Batteries not available (fuse fail)

High/Low voltage protection may be integrated in

the DC/DC converter functionality or implemented

separately. The output voltage must be in the

range 18-31V DC.

Hydraulic Power Supply (HPS)

The purpose of the HPS unit is to deliver the

necessary high pressure hydraulic oil flow to the

hydraulic cylinder units (HCU) on the engine at

the required pressure (approx. 300 bar) during

startup as well as in normal service.

As hydraulic medium, normal lubricating oil is

used, and it is in the standard execution taken

from the main lubricating oil system of the engine.

Hydraulic power is supplied by two electrically

driven pumps. The pumps are of the variable dis-

placement type and are the same size. The dis-

placement of the pumps is hydraulically controlled

to meet the pressure set point from the ECS.

The sizes and capacities of the HPS unit depend

on the engine type. Further details about the lu-

bricating oil/hydraulic oil system can be found in

Chapter 8.

Loading...

Loading...