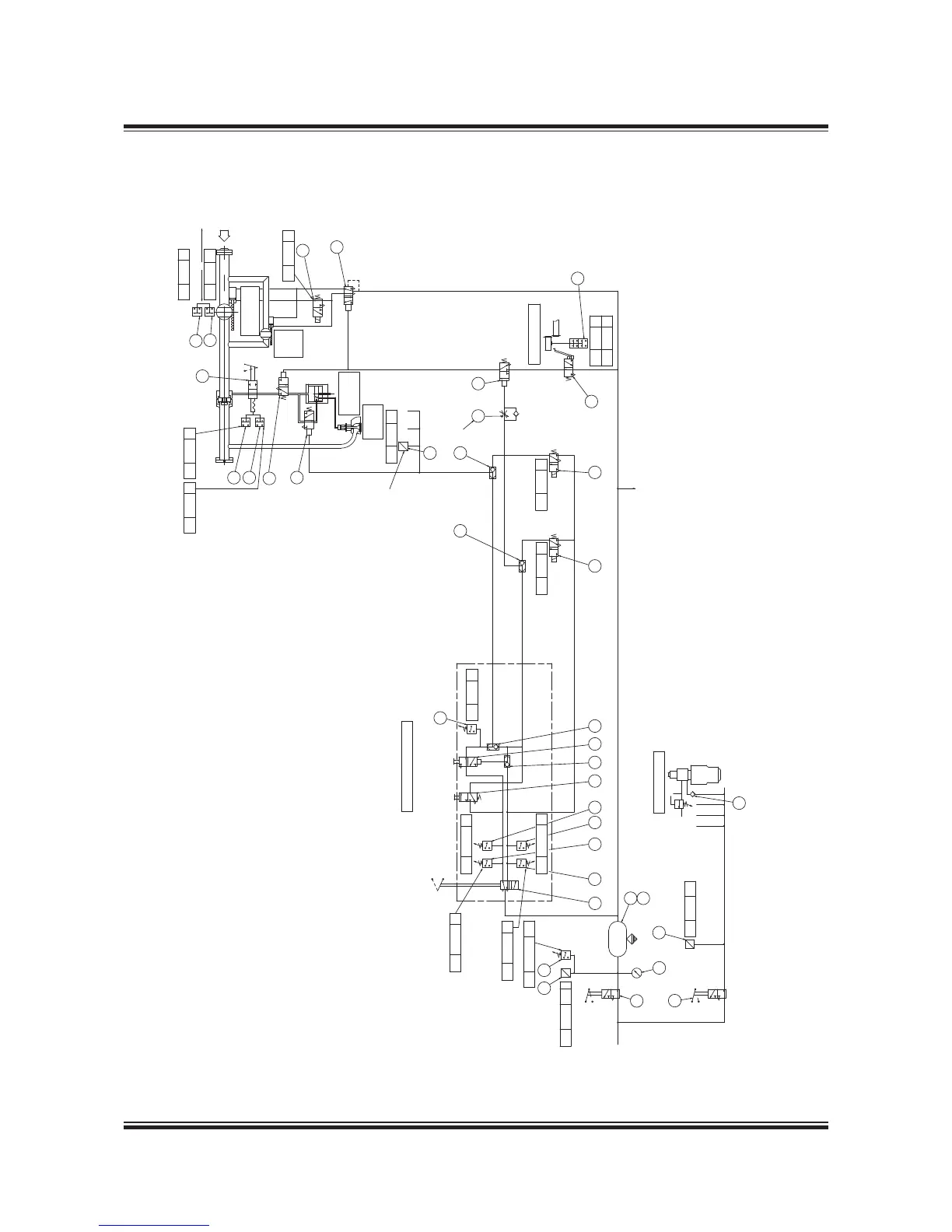

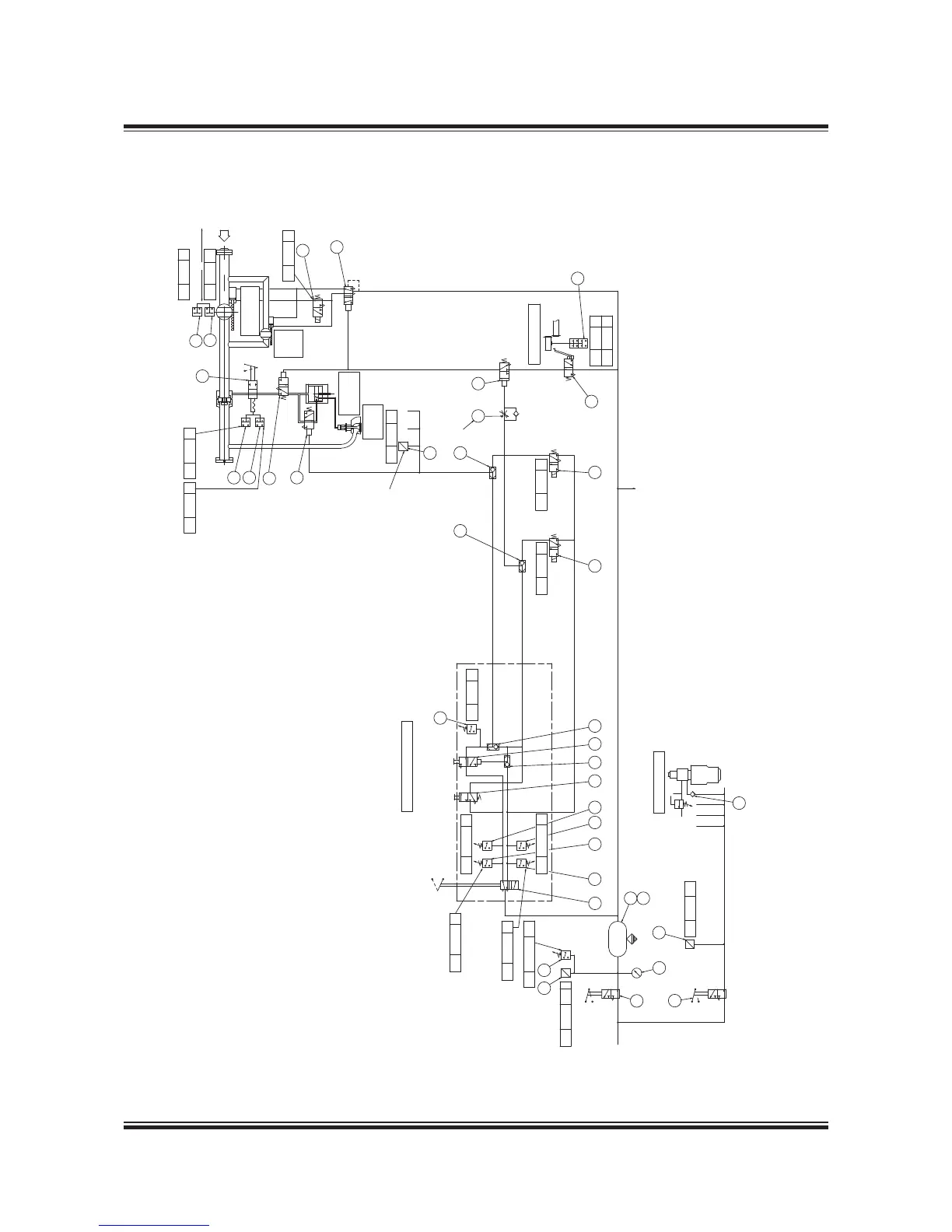

Pneumatic Manoeuvring Diagram, CPP

509 12 04-5.1.0

Fig. 16.01.04b: Pneumatic Manoeuvring Diagram, Controllabe Pitch Propeller (CPP)

Service / Blocked

4

2

14

2

1

3

12

1

3

2

1

ø16x2

Turning gear

2

1

4

14

2

ø16x2

ø16x2

118

121

120

116

32

119

117

5

B

A

P

S

R

115

27

33

90

1

20

6

1

4

12

3

A

R1

P1

A

R1

P1

5

6

162

84

163 103

100

P1

A

R1

R1

P1

A

101 102

B

A, B refer to list of ‘Counterflanges’

A

B

26

A

21

Output for

Oil Mist Detector

Subfunction 217410

48

85

91

137

114

3

5

PS 1106 C

ZV 1136 C

ZV 1137 C

ZV 1109 C

ZS 1112 C

ZS 1111 C

ø16x2

ø16x2

A

R2P2

Slowturning

28

ZV 1114 C

PS 11182 C

PS 11181 C

PS 11301 C

83

107

PS 85032 AH

PT 8503 AL I

2 4

138

PT 8505 AL

ZV 1110 C

PT 1101 C

160

One pressure transmitter

per CCUunit

108

20 L

Pipe dimevnsion ø10x1.5

except where otherwise stated

The drawing shows the system in the following conditions:

Manual control

Stop position,

Pneumatic pressure on,

El. power on,

Main starting valve locking device in service position.

Safety relief valve

set point: 23 bar

Exhaust valve

Control Air

Supply

StopStart

Stop

Stop

Start

Start

Engine side console

Remote control

Manual control

Set point: 1 sec.

Starting

valve

Starting air

distributor

Main starting

valve

Slow

turning

valve

PS 11302 C

ZS 1116 C

ZS 1117 C

Loading...

Loading...