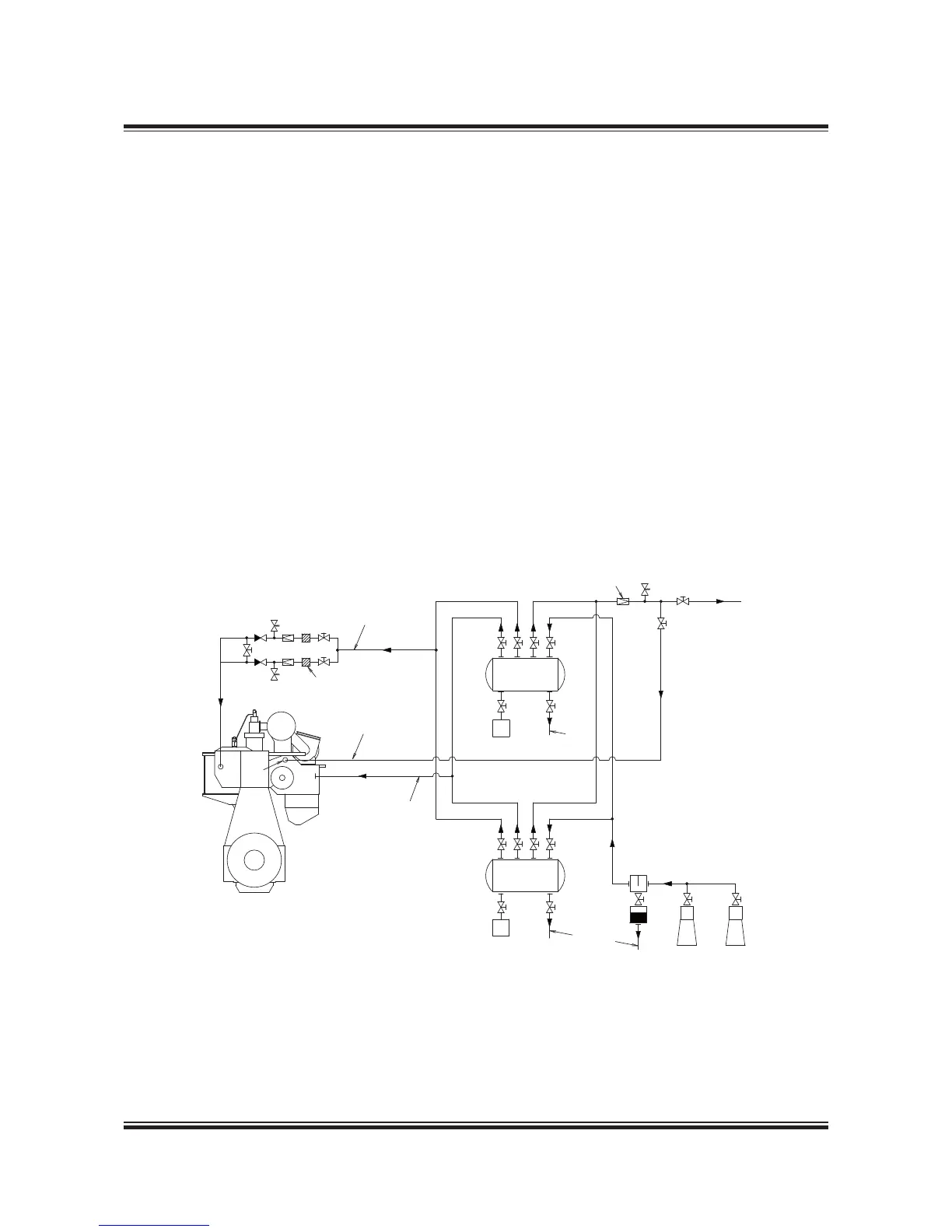

Fig. 13.01.01: Starting and control air systems

The starting air of 30 bar is supplied by the start-

ing air compressors to the starting air receivers

and from these to the main engine inlet ‘A’.

Through a reduction station, filtered compressed

air at 7 bar is supplied to the control air for ex-

haust valve air springs, through engine inlet ‘B’

Through a reduction valve, compressed air is sup-

plied at 10 bar to ‘AP’ for turbocharger cleaning

(soft blast), and a minor volume used for the fuel

valve testing unit.

Please note that the air consumption for control

air, safety air, turbocharger cleaning, sealing air

for exhaust valve and for fuel valve testing unit are

momentary requirements of the consumers.

The components of the starting and control air

systems are further desribed in Section 13.02.

For information about a common starting air sys-

tem for main engines and MAN Diesel auxiliary

engines, please refer to our publication:

Uni-concept Auxiliary Systems for Two-Stroke Main

Engines and Four-Stroke Auxiliary Engines

The publication is available at www.marine.man.eu

→ ’Two-Stroke’ → ’Technical Papers’.

078 83 76-7.3.0

Oil & water

separator

To bilge

Reduction station

Pipe, DN25 mm

Pipe a, DN *)

Starting air

receiver 30 bar

Starting air

receiver 30 bar

Filter,

40 µm

To

bilge

Main

engine

Air compressors

To fuel valve

testing unit

B AP

A

Reduction valve

PI

PI

Pipe, DN25 mm

The letters refer to list of ‘Counterflanges’

*) Pipe a nominal dimension: DN100 mm

Starting and Control Air Systems

Loading...

Loading...