PTO/RCF

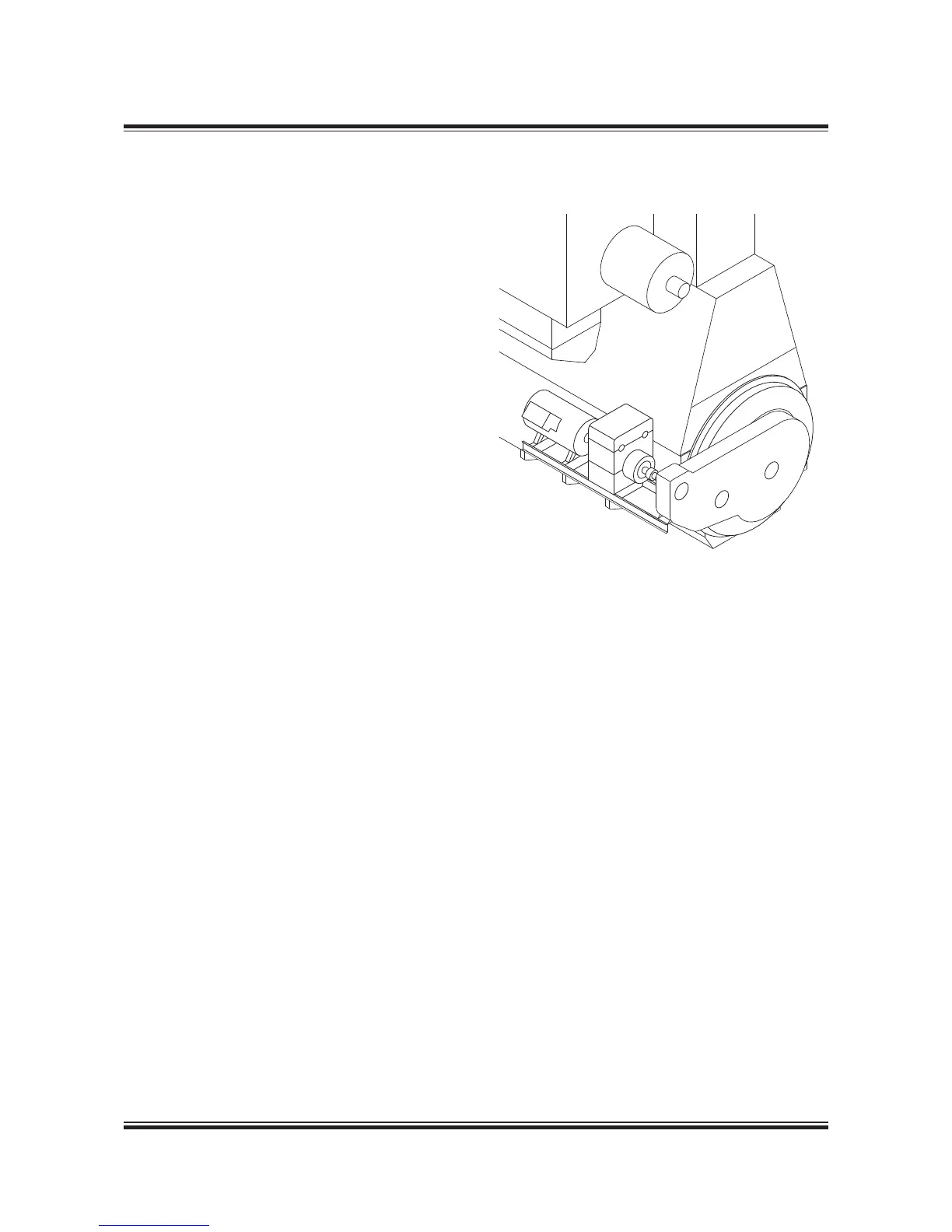

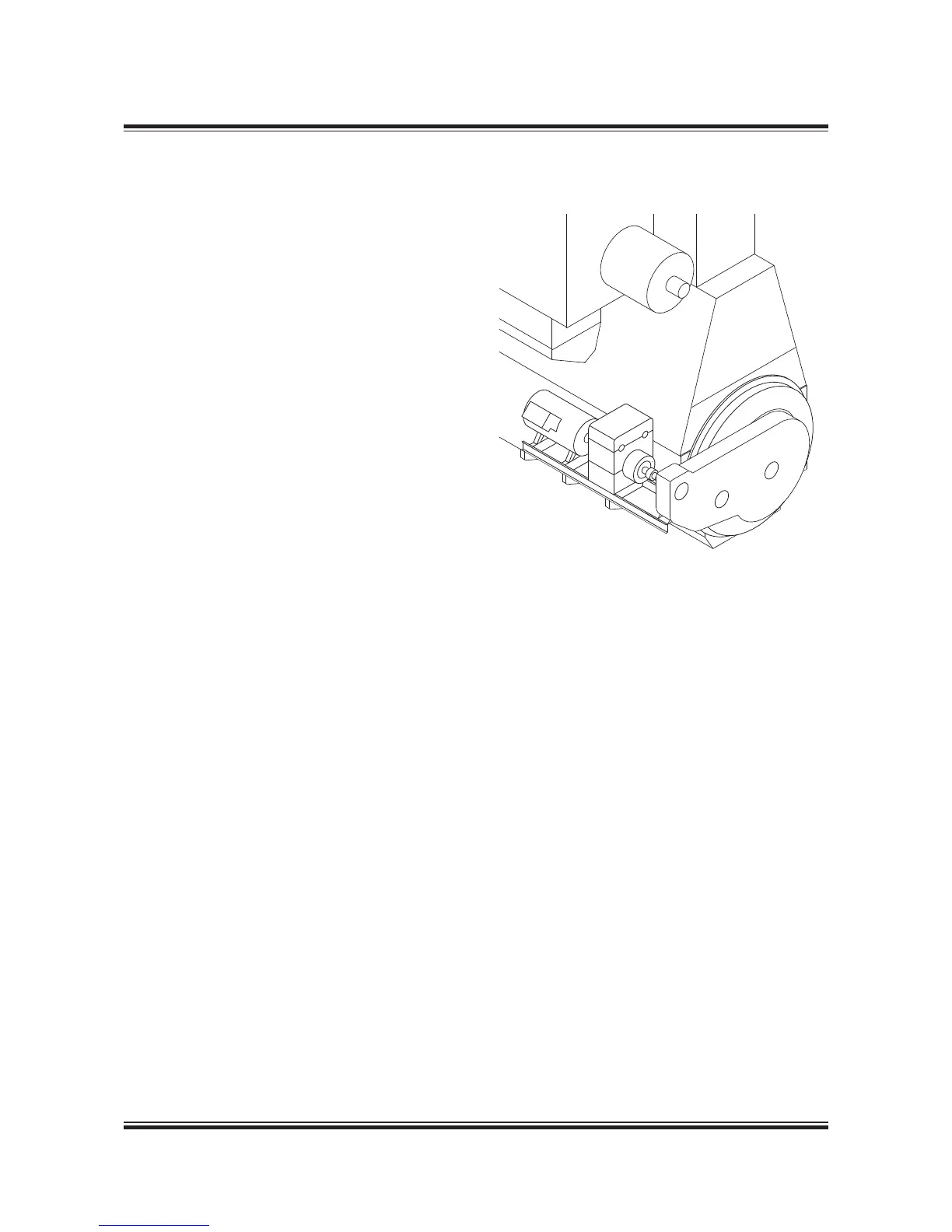

Side mounted generator, BW III/RCF

(Fig. 4.01.01, Alternative 3)

The PTO/RCF generator systems have been de-

veloped in close cooperation with the German

gear manufacturer RENK. A complete package

solution is offered, comprising a flexible coupling,

a stepup gear, an epicyclic, variableratio gear

with builtin clutch, hydraulic pump and motor,

and a standard generator, see Fig. 4.01.04.

For marine engines with controllable pitch propel-

lers running at constant engine speed, the hydrau-

lic system can normally be omitted. For constant

speed engines a PTO/GCR design is normally

used.

Fig. 4.01.04 shows the principles of the PTO/

RCF arrangement. As can be seen, a stepup

gear box (called crankshaft gear) with three gear

wheels is bolted directly to front- and part side

engine crankcase structure. The bearings of the

three gear wheels are mounted in the gear box so

that the weight of the wheels is not carried by the

crankshaft. Between the crankcase and the gear

drive, space is available for tuning wheel, counter-

weights, axial vibration damper, etc.

The first gear wheel is connected to the crank-

shaft via a special flexible coupling, made in one

piece with a tooth coupling driving the crankshaft

gear, thus isolating the gear drive against torsional

and axial vibrations.

By means of a simple arrangement, the shaft in

the crankshaft gear carrying the first gear wheel

and the female part of the toothed coupling can

be moved forward, thus disconnecting the two

parts of the toothed coupling.

The power from the crankshaft gear is trans-

ferred, via a multidisc clutch, to an epicyclic

variableratio gear and the generator. These are

mounted on a common PTO bedplate, bolted to

brackets integrated with the engine crankcase

structure.

178 06 49-0.0

The BW III/RCF unit is an epicyclic gear with a

hydrostatic superposition drive. The hydrostatic

input drives the annulus of the epicyclic gear in ei-

ther direction of rotation, hence continuously vary-

ing the gearing ratio to keep the generator speed

constant throughout an engine speed variation of

30%. In the standard layout, this is between 100%

and 70% of the engine speed at specified MCR,

but it can be placed in a lower range if required.

The input power to the gear is divided into two

paths – one mechanical and the other hydro-

static – and the epicyclic differential combines the

power of the two paths and transmits the com-

bined power to the output shaft, connected to the

generator. The gear is equipped with a hydrostatic

motor driven by a pump, and controlled by an

electronic control unit. This keeps the generator

speed constant during single running as well as

when running in parallel with other generators.

Fig. 4.01.03: Side mounted BW III/RCF

Loading...

Loading...