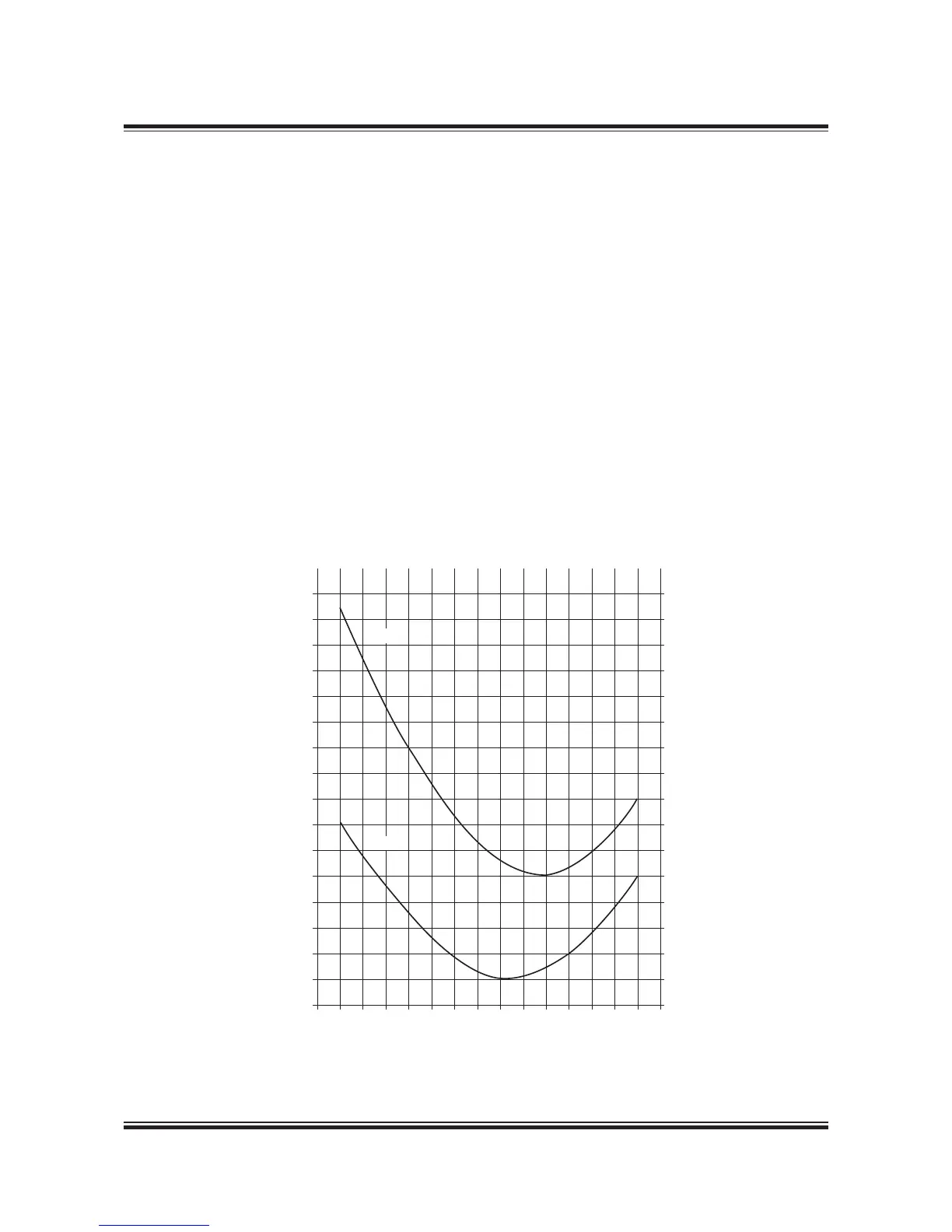

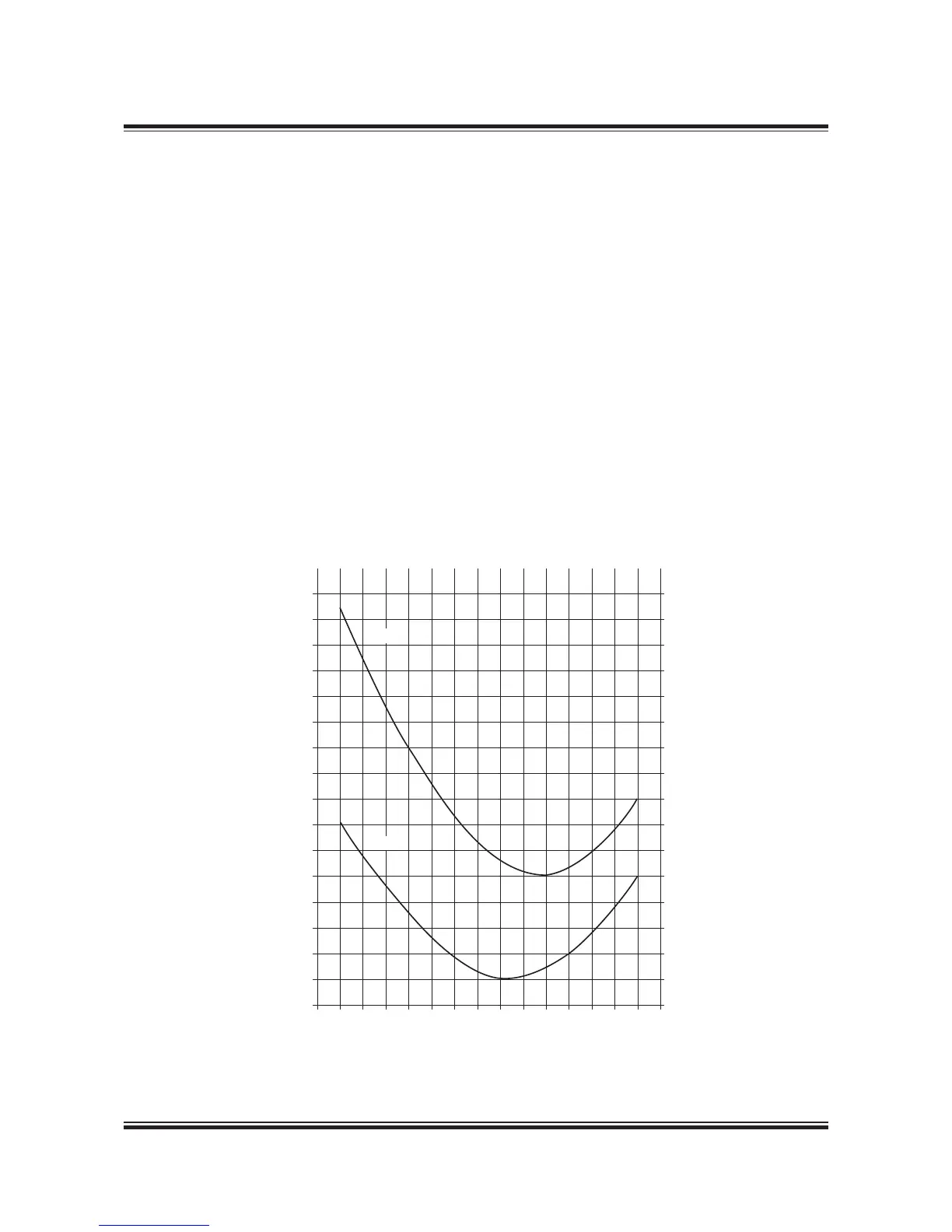

Specific Fuel Oil Consumption, ME versus MC engines

Fig. 2.06.01: Example of part load SFOC curves for ME and MC with fixed pitch propeller

198 97 389.3

As previously mentioned the main feature of the

ME/ME-C engine is that the fuel injection and the

exhaust valve timing are optimised automatically

over the entire power range, and with a minimum

speed down to around 15-20% of the L

1

speed,

but around 20-25% for MC/MC-C.

Comparing the specific fuel oil comsumption

(SFOC) of the ME and the MC engines, it can be

seen from the figure below that the great advan-

tage of the ME engine is a lower SFOC at part

loads.

It is also noted that the lowest SFOC for the ME/

ME-C engine is at 70% of M, whereas it is at 80%

of M for the MC/MC-C/ME-B engine.

For the ME engine only the turbocharger matching

and the compression ratio (shims under the piston

rod) remain as variables to be determined by the

engine maker / MAN Diesel & Turbo.

The calculation of the expected specific fuel oil

consumption (SFOC) valid for standard high load

optimised engines can be carried out by means of

the following figures for fixed pitch propeller and

for controllable pitch propeller, constant speed.

Throughout the whole load area the SFOC of the

engine depends on where the specified MCR

point (M) is chosen.

Loading...

Loading...